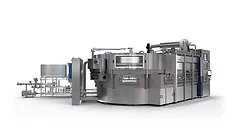

Packaging Equipment

Coverage dedicated to packaging equipment trends, new releases and advancements.

Articles

More ArticlesElevate your expertise in the beverage marketplace with unparalleled insights and connections.

Join thousands of beverage professionals today. Shouldn’t you know what they know?

JOIN NOW!Copyright ©2026. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing