Packaging Equipment

Filler technology turns to AI for future of equipment

Sensitive filling demands continue to proliferate

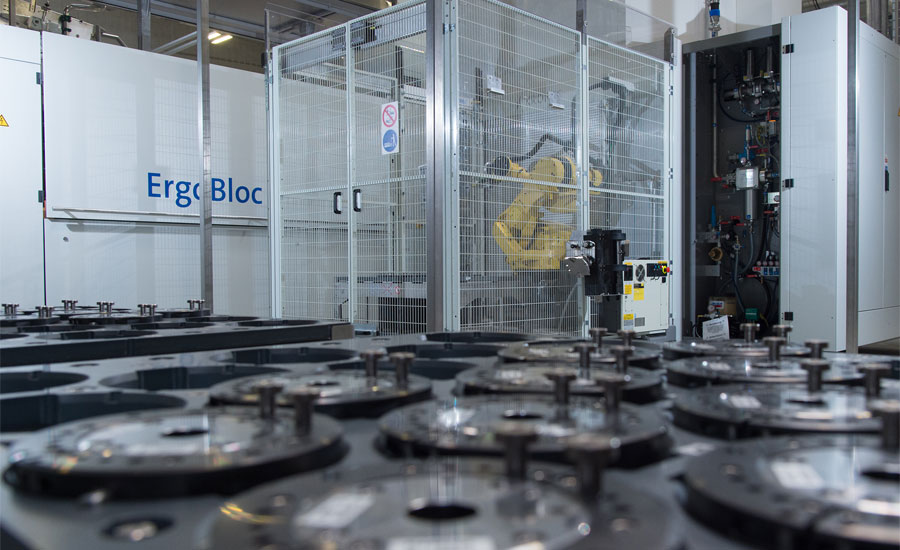

Image courtesy of Krones Inc.

In the animated series “Inspector Gadget,” the title character is able to take down the bad guys with his niece Penny and dog Brain thanks to a host of go-gadgets, including his Gadget Coat, featuring an airbag; the Gadget ‘Copter, which emerges from his hat; Gadget Cuffs, handcuffs that emerge from his forearm, and much more. Despite some of Inspector Gadget’s bumbling, the versatility of his gadgets keep the investigator on task. As beverage-maker’s need to do more with today’s filling equipment, they also are in need of versatile gadgets.

Among the trends driving this has been the proliferation of SKUs whether that be in terms of pack sizes, flavor expansions as well as the use of new age ingredients.

Giacomo Bello, director of aseptic filling technology sales at Krones Inc., Franklin, Wis., notes that the company continuously is challenged to supply equipment that delivers the highest agility when it comes to changeover.

Barry Fenske, technical sales of the filling division at Krones, echoes similar sentiments.

“Designing flexibility into the filler is critical, which allows for running several product types on the same filler,” he says. “There are machines that can run carbonated or non-carbonated beverages, hot or cold fill ― all on one machine. We incorporated a design years ago that allows for quick product changeovers of 10 minutes or less for compatible products.

“Basically, the filler is filling the last bottles with ‘flavor A’ while the blender is ramping up for ‘flavor B,’” Fenske continues. “We have automated product changeover technology called LineXpress which enables a quick changeover of the entire line.”

For example, the LineXpress has the ability to increase line efficiency by up to 20%, according to the company. This is thanks to reduced product changeovers to up to 10 minutes and reduced format changeovers to up to 30 minutes.

Noting the increasing need to reduce changeover times, Krones’ Bello highlights that artificial intelligence (AI) is helping to meet this need state.

“Filling technology has adapted with increased flexibility requests with engineering measures to decrease the changeover times,” he says. “Digitalization and artificial intelligence (AI) are now also key factors guiding the machine when automatic changeover is present, or the operators, when manual changes are required.”

Image courtesy of Krones Inc.

Safe and secure

As much as efficient, quick practices are in demand, suppliers know that those become null and void if efficacy and safety are ignored. As such, original equipment manufacturers (OEMs) are designing filler technology that can support all of these need states.

What’s also influencing the safety and efficacy of filling equipment are shifts in processing trends. Bello notes that proliferation of beverage-makers avoiding preservatives has prompted a shift toward aseptic solutions. He adds that the Food & Drug Administration’s Food Safety Modernization Act (FSMA) is providing rules and guidance for foods and beverages that were not regulated previously.

“This requires the goods’ manufacturers to comply with more stringent protocols and increased standards, which include ingredients and products traceability,” Bello says.

Krones’ Fenske notes given the rise in requests to support these sensitive products, the company has developed equipment to meet those needs.

“More and more requests come in for filling sensitive products,” he says. “Krones has come up with our most hygienic can filler yet ― the Modufill Can Filler with Compact Clean Room Design.”

The machine unites conventional and aseptic filling technology, the company notes, and features a closed cleaning systems to ensure simultaneous exterior and interior cleaning of the treatment area, filling valves and additional pipe system.

In conjunction with safe filling operations, OEMs also are navigating shifts in the materials for primary packaging.

“Continuous light-weighting of packaging materials, and demand for production lines with higher speed are important inputs to design the lines of the future,” Krones’ Bello says.

Given the emphasis put on sustainability of operations as well as safety, Krones’ Fenske says filler technology continues to see “improvements in hygienic design, lowering the carbon footprint, creating less waste, reducing the customer’s total cost of ownership (TCO) and creating a line that adapts to changes on the fly in real time.”

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!