Packaging Equipment

Filling Technology keeps pace with changing beverage landscape

Sustainability, SKU proliferation continue to drive innovations

Singer, songwriter and musician Hank Williams Jr. is quoted for saying: “Listen, ladies and gentlemen. America is still a country of choices and options. And I have a lot of them.”

With beverage-makers offering consumers a wide array of drink options — leading to an increasing number of SKUs — experts note that filling technology has adapted to support these growing portfolios.

“SKU proliferation influences the variety of features required on a given filling machine to manage packaging for properly rinsing, filling and capping of products,” says Karl Walby, director of sales at Holland, MI-based Fogg Filler, a ProMach brand.

“Additionally, SKU variety increases and challenges packaging validation for sterility and shelf life along with the cleaning features, process features, chemistry and rinse combinations required to achieve the preferred product stability while retaining flavor profiles,” Walby continues.

Rick Feuling, sales director for North America at KHS USA Inc., Waukesha, WI, says that with SKU expansion the need for flexible filling equipment is a given.

“The growing volume of SKUs forces equipment manufacturers to be nimble in providing machines that reduce/eliminate the time that it takes to changeover; as well as container or product loss,” he explains.

Barry Fenske, product manager of filling technology at Krones Inc., Franklin, WI, echoes similar sentiments, noting that designing flexibility into the filler is critical, which allows for running several product types on the same filler.

“There are machines that can run carbonated or noncarbonated beverages, hot or cold fill — all on one machine,” he says. “We incorporated a design years ago that allows for quick product changeovers of 10 minutes or less for compatible products. Basically, the filler is filling the last bottles with ‘flavor A’ while the blender is ramping up for ‘flavor B.’

“We have automated product changeover technology called LineXpress, which offers fully automated performance for essential processes,” Fenske continues.

Fogg Filler’s Walby explains how technology designers are working to streamline changeover practices.

“Filling technology designers are evaluating and implementing creative change part designs, bottle neck alignment, fill valve centering features and filler valve designs to better manage SKU varieties and group them according to common geometries focused on limiting changeover frequency,” he says. “Fogg has even patented universal change parts applicable to select types of products that permit in situ adjustment of bottle guides that adapt to multiple SKU families and minimize downtime at roughly 4:1 time savings during SKU changes.”

KHS’ Feuling notes how KHS is making strides in reducing the changeover time for container to container changes, as well as product to product.

“In our latest SmartCan can filler package, jointly developed with Ferrum, we reduce the can diameter changeover from 45 minutes down to 22 minutes (filler plus seamer),” he says. “Making format parts lighter and easier to access attributes to the reduced timing.”

Trends that have influence

Alongside SKU proliferation, experts highlight how sustainability trends are impacting filler equipment.

“Reduction in electricity, water, CO2 and N2 are paramount in new technology design,” KHS’ Feuling says. “Within the industry it’s a race to provide the most flexible equipment while having the lowest carbon footprint possible. All new designs take this into consideration — this wasn’t the case even 20 years ago. Additionally retrofits and upgrades are possible to reduce the amount of utilities consumed.”

Krones’ Fenske echoes similar sentiments, also noting the impact of lightweighting beverage containers.

“Probably the biggest impact I see is the lightweighting of cans and bottles. You can only lightweight so far before an issue arises,” Fenske says. “The main focus for filling sustainably is utility consumption reduction. Using less air, electricity, CO2, water, etc., and filling warm where traditionally you filled cold, which reduces cooling costs ahead of the filling and warming costs post filling without impacting function or quality.”

Fogg Filler’s Walby highlights how the lightweighting of plastics are impacting filling technology.

“Rigidizing ribs required to maintain package integrity influences bottle design as package weight is reduced. Rib orientation in the bottle body and base, bottle dimension and geometry can make sterilization more difficult,” he explains. “Meanwhile, as weight is reduced structural integrity may be compromised encouraging ‘bagging’ through feed screws, bottle pockets and starwheel transfers driving innovative package handling designs to prevent product loss and maintain filling/capping alignment, filler cleanliness, and production rates.

“In the absence of bottle handling innovation machine run rates could slow and subsequently production rates may be compromised to overcome lightweighting influences in new or existing machines,” Walby continues.

Yet, where sustainability trends and SKU proliferation is driving innovation, Walby points to how both issues are influenced by beverage market trends.

“Trends in ready-to-drink (RTD) beverages in a variety of market segments along with subsequent product varieties and processing methods are influencing SKU proliferation, production volumes, and sustainability initiatives that, in turn, influence filler technology,” he explains. “The trend toward distilled spirits over beer and wine and in parallel with RTD are driving innovation toward improved rinsing technologies and greater fill speeds within reduced machine footprints.

“The single barrel trend is also influencing filler innovation to capture contents down to the last drop while expediting barrel change-out,” Walby continues.

KHS’ Feuling points to how packaging trends also are influencing filler innovation.

“Container trends also factor into technology [with] aluminum bottles being at the forefront of innovation,” Feuling says. “Often aluminum bottles are run on glass bottle filling technology. Adaptations and new tech look to showcase aluminum bottle filling capabilities and push the current boundaries.”

Krones’ Fenske points to the increasing demand for technology that addresses filling sensitive products.

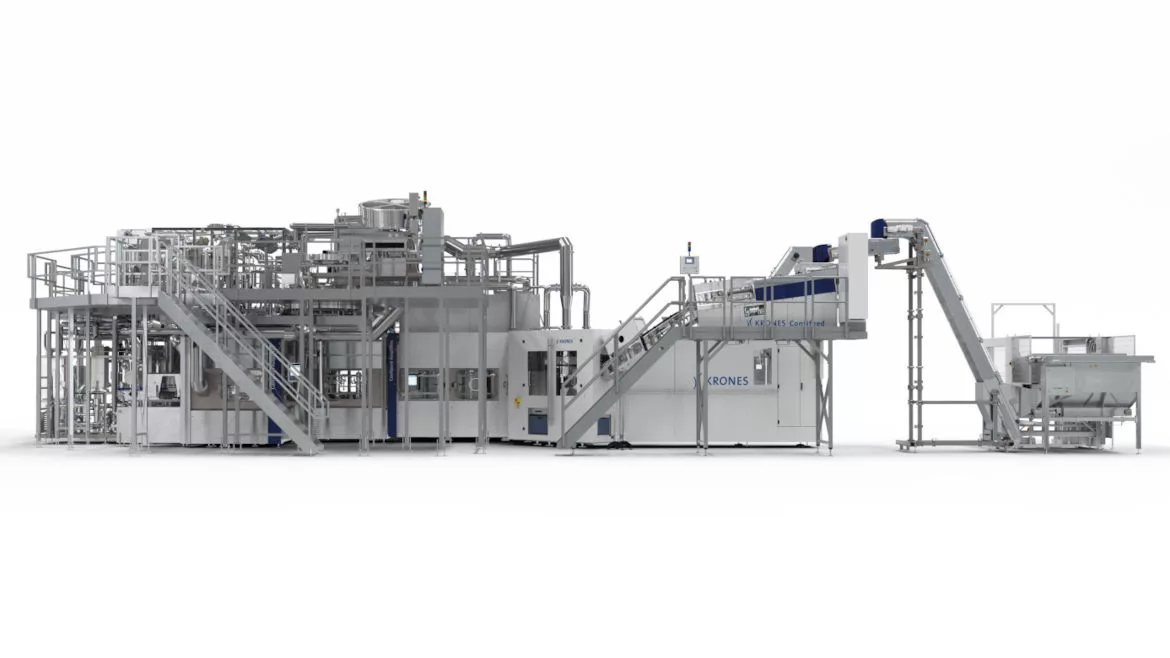

“More and more requests come in for filling sensitive products, which may be why our Contipure AseptBloc has become so popular, as every production step — blow molding, filling and capping is safely included in one aseptic processing chain,” he says. “Also, Krones has come up with our most hygienic can filler yet — the Modufill Can Filler, which is available with Compact Clean Room design with a hygienically designed filler carousel and infeed module construction.”

Innovations for the future

As filler technology addresses product safety issues, supports sustainability measures, SKU proliferation and more, experts highlight that artificial intelligence (AI) shows potential to complement existing technologies.

“AI can complement food safety, sustainability measures, and influential trends through expedited data management, feed forward and post fill inspection and controls with real time data and analysis that can reduce pathogen and microbial proliferation while optimizing and increasing production efficiency,” Fogg Filler’s Walby says. “AI will expedite the future of innovation, design and simulation capabilities for machine designers and food scientists alike.”

Krones’ Fenske notes how the company has already implemented artificial intelligence (AI) into its designs — from the first machine to the last machine.

“Not long from now, lines will be able to diagnose and adjust to changing conditions without human intervention,” he says. “An example of such a technology can be found in our Linatronic AI smart bottle inspection.”

KHS’ Feuling says that AI will be a game changer, especially in the preventative and indicative maintenance sectors.

“Using AI to analyze the existing data can automatically trigger maintenance suggestions, warnings, or even order parts for components in question,” he explains.

Feuling adds that, currently, he is excited about KHS offering “a full scope of industry services, while reducing carbon footprint, implementing AI and keeping up with the changing market trends.”

Krones’ Fenske notes that he’s enticed by the company’s “improvements in hygienic design, lowering the carbon footprint, creating less waste, reducing the customer’s [total cost of ownership] (TCO), and creating a line that adapts to changes on the fly in real time.”

Fogg Filler’s Walby says that he’s excited about contributing to filler innovation, food safety, and being a catalyst in its implementation.

“Microbes will continue to multiply, and pathogens will try to infiltrate our food and beverage products, marketers will continue to be creative, and SKUs will continue to proliferate, trends will be dynamic — filling machine manufacturers and food scientists will continue to innovate,” he concludes.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!