Home » Keywords: » beverage equipment

Items Tagged with 'beverage equipment'

ARTICLES

Government regulations, digitalization have growing influence on plastic bottle equipment

Read More

Plastic bottle manufacturers help beverage operations tackle sustainability goals

Changeover efficacy vital to accommodate new products, packaging

October 24, 2024

Channel Strategies

Foodservice channel demonstrates growth over past year

Experts anticipate channel will continue to grow

July 3, 2023

Channel Strategies

Foodservice industry regains footing after multiple years of decline

New, innovative offerings play key role in beverage’s performance within the channel

June 21, 2022

Coca-Cola Freestyle 8100 brings beverage variety, quality and speed to drive-thrus

Company debuts new dispenser model at 2022 National Restaurant Association Show

May 17, 2022

Operations

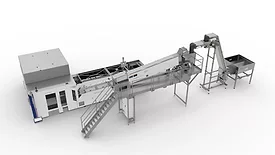

Revamped equipment saves beverage manufacturers time, money

Pandemic contributes to demand for refurbished equipment

August 2, 2021

Packaging Equipment

Inspection equipment offers brand protection, combats counterfeiting

Slim cans create need for more inspection expertise

July 2, 2021

Charles Ross unveils conical vessel that handles 10-30 gallons a minute

Model VSL-400 features 400-gallon mixing and pumping skid system

September 4, 2020

Operations

Refurbished equipment makes mark in beverage industry

Like-new machines save end user about 50 percent

July 22, 2020

Grieve Corp. unveils new electrically-heated belt conveyor oven

No. 853 cures and heat-shrinks plastic

February 25, 2020

Elevate your expertise in the beverage marketplace with unparalleled insights and connections.

Join thousands of beverage professionals today. Shouldn’t you know what they know?

JOIN NOW!Copyright ©2026. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing