Packaging Equipment

Labeling equipment fosters the need for speed

Equipment handles diverse needs of beverage-makers

In Walt Disney’s 1937 animated classic “Snow White and the Seven Dwarfs,” the dwarfs sing “Heigh-ho, Heigh-ho, it’s home from work we go,” as they whistle a happy tune en route from the diamond mine. Like the Seven Dwarfs, labeling equipment suppliers are working hard to find that “diamond in the rough” — fast, flexible and thinner labeling solutions to bolster brand performance and increase recyclability.

Experts note that the COVID-19 pandemic has increased market demand for companies that are adding SKUs to their production and even packaging and labeling specially made hand sanitizer bottles to support COVID-19 efforts and shortages, says Brook Hollo, product manager for labeling and inspection technology at Krones USA, Franklin, Wis.

Given that there are a diverse and widening array of beverages such as craft beers, hard seltzers and wines being packaged in cans, pre-printed cans currently are more difficult to access because of stock shortages, he says.

“As always, speed capability and line flexibility as a whole are the main changes our customers ask for,” he explains. “Our labeling equipment must be the fastest and most accurate as packaging design complexity and consumer demand for high-end products increases. We are seeing thinner materials emerge, which our machines must accommodate, along with unique bottle designs that require our expertise in handling properly.”

Justin Slarks, director of marketing at Little Rock, Ark.-based Sleeve Seal, thinks that the pandemic has increased the need for tamper-evident bands and facilitated the usage of more intelligent automated machines that rely on less operator control to “take the guesswork out of the equation,” he says.

The type of label, particularly thinner recyclable film and shrink labels, and the dimensions of the label are being used more regularly because beverage brands save on the shipping costs of labels, raw materials and changeover times — all good things, Slarks adds.

“The challenge has always been the same — brand recognition and the fight for shelf appeal,” Slarks says. “Our machines are applying labels at high speeds on uniquely shaped containers with very tight tolerances. The ‘tea in square bottles’ has been a home run for one of biggest customers and we have replaced many of our competitor’s machines because we can place a label on a square bottle accurately at speed.”

A seam down the side

With customers needing labeling equipment to perform more tasks, original equipment manufacturers are streamlining today’s machines to fulfill those need states.

Tamper-evident vertical perforations down the side of shrink-sleeve bottles are making it easier for customers to remove the film completely and easily from the bottle while upping the recyclability game, says Michael Johnston, tunnel testing and development technician at PDC International.

The Norwalk, Conn.-based company also is seeing an elevated interest in customers seeking high efficiency machines, while questioning what type of shrink film best fits their packaging and whether there is enough shrink percentage to produce favorable, consistent results.

“Is the coefficient of friction (COF) of the film too low or too high?,” Johnston asks. “Too high and it will cause drag when applying that may lead to a film jam or breakage. Properties, such as coloration, use of metallics, and how the film was manufactured, all play a role in performance. … We look at the line speed, is the container empty or full, or if full, what is the fill temperature? What is the material of the container? Is it prone to melting or deforming?”

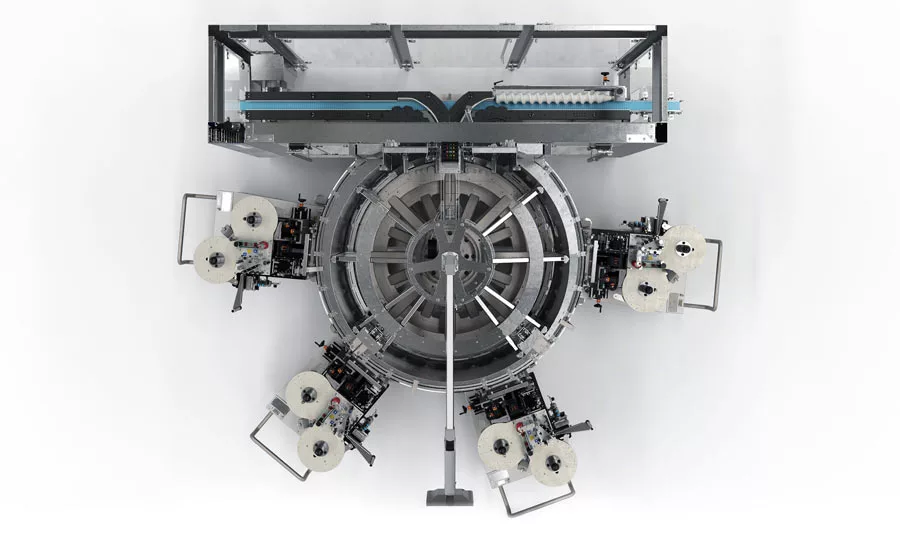

Customers also should carefully consider material type, shape and size of the container and what condition the film will be in prior to labeling. “[W]ill it be hot or cold, wet or dry — these are all very important,” Krones USA’s Hollo says. “… With our latest Ergomodul labeler, we are able to handle all these packaging needs through exchangeable aggregates that dock to the machine when needed.”

Whether the machine is handling self-adhesive labels or roll-fed labels, the Erogmodul labeler can easily handle both setups, Hollo states. “With speed capabilities up to 81,000 containers anr hour and the ability to handle the most popular labeling technologies, our Ergomodul is unmatched.

“This labeler is the ultimate end when it comes flexibility, efficiency and ergonomics which allows our customers to be the most adaptable and successful in the market,” he continues.

The need for speed

To ensure that labeling equipment applies labels properly, PDC’s Johnston points out that sensors, band positioner devices, band placement inspection units or mandrel or tooling design makes sure that the shape of the container matches the equipment.

Krones Inc.'s Hollo notes that inspection technology and labeling equipment go hand in hand through the use of its Checkmate inspection series. “With capabilities to inspect for label presence, correct SKU, label placement, barcodes and much more, our Checkmate provides the ultimate reassurance to our customers that each product coming off the line with meet the quality required for the shelves.”

In addition to the Ergomodul and the Checkmat inspection series, Krones also offers the DecoType, a digital direct print decoration technology for primary packaging; and the Autocol Inline, a pressure-sensitive labeler with a small footprint design that can accommodate different can and round bottles sizes at speeds of as many as 15,000 cans an hour. For larger, higher speed lines, the rotary style Autocol machine has the capability to label as many as 66,000 containers an hour, Hollo says.

Hollo adds, “We expect higher speed requirements, thinner label materials and more unique package designs and sizes to propel the industry forward.”

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!