Home » Keywords: » packaging machinery

Items Tagged with 'packaging machinery'

ARTICLES

Adjusting for the manufacturing market

Frain Industries delivers access to packaging, processing equipment for beverage manufacturers

October 13, 2023

Packaging Equipment

Inspection equipment protects beverages while maintaining speed

Artificial intelligence’s use in inspection systems still in development

June 30, 2023

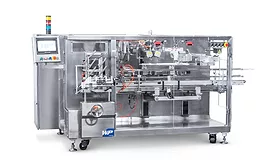

WeighPack unveils automated coffee bagging system

October 5, 2022

Operations Perspective

Packaging lines affected by speed, complexities

Line speed must focus on fillers

September 23, 2021

Packaging Materials

Consumers, trends impact secondary packaging

Sustainability, smart technology influence packaging design

July 6, 2021

New Esko WebCenter 20.0 streamlines packaging development approval process

Software manages packaging and label production

January 29, 2021

Elevate your expertise in the beverage marketplace with unparalleled insights and connections.

Join thousands of beverage professionals today. Shouldn’t you know what they know?

JOIN NOW!Copyright ©2026. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing