Home » product safety

Articles Tagged with ''product safety''

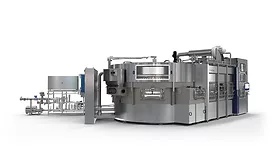

Automation in filling, seaming equipment addresses product safety issue

Read More

Legislation, automation drive lubricant usage in beverage manufacturing

Sustainability, corporate responsibility influence next generation of lubricants

November 25, 2025

High Noon issues recall of Beach Variety pack lots

Some packs contain mislabeled CELSIUS ASTRO VIBE Energy Drink, Sparkling Blue Razz Edition cans

July 31, 2025

Sustainability keeps labeling materials on the front-end of innovation

Suppliers stress importance of compatibility with labels and containers

July 24, 2025

Battling wine fraud with the Internet of Things

New IoT solutions help wine industry implement science-backed authentication

July 15, 2025

Certifications, applications advance beverage development

Association of Vanilla Exporters of Uganda Limited announces record export year

July 10, 2025

Ingredient launches, acquisition heat up supplier market

NutriScience Innovations acquires XSTO Solutions

December 10, 2024

Food grade lubricants protect products, deliver on sustainability

Synthetic, bio-based solutions both in demand for beverage manufacturing

November 19, 2024

Elevate your expertise in the beverage marketplace with unparalleled insights and connections.

Join thousands of beverage professionals today. Shouldn’t you know what they know?

JOIN NOW!Copyright ©2026. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing