Advanced technology helps can filling, seaming equipment meet beverage market trends

Automation in filling, seaming equipment addresses product safety issue

In gymnastics, a sport that requires strength, flexibility and balance, the attire that gymnasts wear is an essential aspect of their performance. Although the design and style of gymnasts’ attire like leotards most likely will evolve with the sport, the basic principle behind their use will remain the same — to enhance a gymnast’s performance.

Similarly, as the beverage industry continues to evolve, can filling and seaming equipment has developed in tandem to address industry challenges such as SKU proliferation, experts note.

“SKU growth and packaging variances have pushed fillers and seamers to deliver faster, simpler and repeatable changeovers,” says Jordan Crawford, product manager at KHS USA, Waukesha, Wis. “Ferrum’s SmartCan seamer was designed with this in mind. Its ultrafast changeovers take half the time of the previous generation of seamers, giving producers flexibility without sacrificing quality.”

Barry Fenske, product manager for filling technology at Franklin, Wis.-based Krones Inc., explains that designing flexibility into the filler is critical for addressing SKU proliferation.

“There are machines that can run carbonated or non-carbonated beverages, hot or cold fill — all on one machine,” he says. “With a filler/seamer block needing to be flexible, changeovers can be impacted, especially at the seamer when there is a lid diameter change. This is especially applicable to co-packers.

Fenske adds that Krones’ fillers are capable of handling a variety of cans on the market with just some additional change parts.

“This makes our canners attractive to co-packers as well,” he says. “Again, changeovers will take longer and if the end user wants to run a slim, standard and King can, the filler/seamer height adjust range needs to be reviewed as well as the lid feeders because some cannot run all the sizes on one unit. This makes faster changeover times a key part of the requirements for the equipment. Further, tool-less change over development and lightweighting of parts must now be handled by operators at higher frequency.”

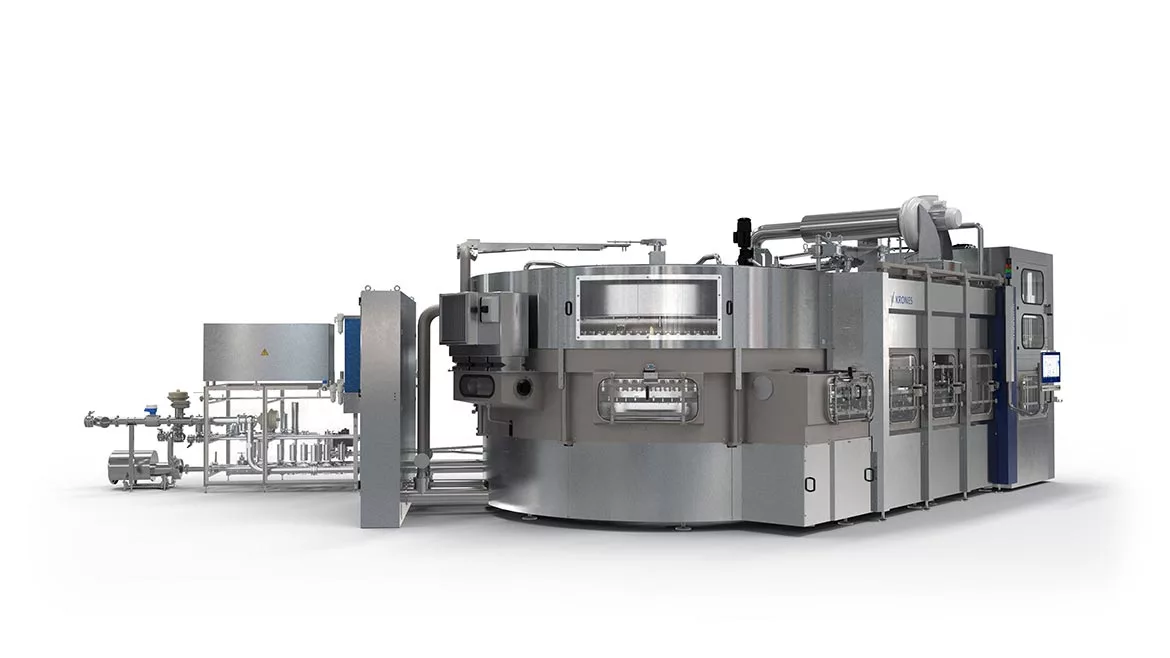

As far as other market trends impacting filling and seaming equipment, Fenske points to more sensitive beverages moving into cans including beverages that normally are packaged by aseptic PET lines.

“Thus, an aseptic can filler/seamer will need to be explored; however, the issue is making the seamer aseptic, which is a tall challenge,” he says. “Krones has come up with our most hygienic can filler yet — the ModulFill VFS-C with Compact Clean Room Design, which also features an optional process area in isolator design in accordance with the dry floor concept.”

KHS’ Crawford also notes how sensitive beverages are impacting filing and seaming equipment.

“The growing market for sensitive beverages and continued lightweighting from can manufacturers are tightening allowable TPO limits and reducing container robustness,” he explains. “In response, filling and seaming equipment must provide tighter oxygen control and gentler format handling to protect both product and package integrity.”

What to consider

As flexibility is a critical factor when selecting can filling and seaming equipment, experts highlight what factors should be taken into consideration when selecting equipment.

“One of the most important considerations is the integration of all system components — from filling and seaming to inspection and packaging,” KHS’ Crawford says. “Each system must work together flawlessly to ensure efficient and consistent production. This level of integration not only reduces the risk of bottlenecks but also enhances overall system performance.

“Flexibility factors like can size, lid size, filling product as well as planned changeover times should be considered,” he continues. “Additionally, future growth opportunities are important, a filler that is just enough to keep up with needs today, might not be fast enough for future endeavors.”

Tommaso Tegoni, product manager for filling at Sidel, Norcross, Ga., echoes similar sentiments.

“Flexibility is key to handling current and future production needs and equipment should accommodate a range of can sizes and beverage varieties, including still, carbonated and hot-fill products, while maintaining accurate fills and consistent seam quality,” he explains. “As a proof of evidence Sidel EvoFILL Can Compact handles formats ranging from 150- to 1000-ml, with no-changeover required for the different can ends (from 200 to 209) and automatic height adjustment.”

Tegoni adds that following the success of Sidel’s original EvoFILL Can filler, the EvoFILL Can Compact addresses the growing demand for flexibility, efficiency and adaptability in the beer and carbonated soft drink sectors, especially within the low-to-medium speed production market.

“EvoFILL Can Compact ensures filling accuracy of plus1-ml (up to 500-ml cans) and product losses below 0.1%. It handles both CSD and hot-fill applications, offering ambient temperature filling for carbonated drinks with carbon dioxide losses of less than 0.2 vol,” Tegoni says. “The system also achieves 98.5% monoblock efficiency, ensuring reliable performance with minimal downtime.”

Krones’ Fenske notes that for can filling equipment, it is becoming more popular to have two seamers blocked to one can filler to help in changeover times for lid diameter changes.

“Handling parts on the fillers need to be quick change,” he says. “Separate recipes in the PLC for each SKU, brought up for that SKU at the touch of a button with very little fine tuning required after changing to another SKU. The machines should be flexible in running various package sizes, and various products and filling temperature considerations. Electrical flexibility for customers that may have multiple locations with different power and utility demands and supplies is also important.”

As far as how filling and seaming equipment is addressing product safety in the face of beverage market trends, Fenske says, “in my opinion, you need more checks and balances.”

“You need a good can (check before rinsing, auto reject if out of spec), correct rinsing media for the application, low oxygen pick-up methods filler/seamer (flush the can at the filling valve with CO2/N2 prior to filling, blanket the can headspace with CO2/N2 prior to lid positioning), check for product fill height post seamer, check the can downstream with an inspection device looking for slow leakers,” he says. “Additionally, lightweighting of change parts that are handled by operators and guarding evaluation and adherence to any unique customer safety specifications specific to the facility.”

KHS’ Crawford explains that automation in filling and seaming equipment can help address product safety issues.

“Further automation of beverage preparation and filling allows producers to monitor product specifications in real time, from their desk,” he says. “This eliminates the uncertainty gaps during production with the traditional periodic lab pull through continuous verification.”

As far as what’s on the horizon in technological advancements, Crawford points to improved performance in hygienic can filling equipment.

“The KHS/Ferrum SmartCan ECO represents the next phase of hygienic can filling with minimized treatment area, fully collected drains across the machine block, and ultra-fast cleaning utilizing a shared CIP & COP concept,” he says. “These advancements are a clear improvement to hygienic performance allowing producers to pack sensitive products with ultimate confidence.”

In a market characterized by rapid SKU proliferation, shifting consumer preferences and a need to deliver on product safety, it’s apparent that advanced fillers and seamers have become crucial to meeting the moment.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!