Home » Keywords: » beverage operations

Items Tagged with 'beverage operations'

ARTICLES

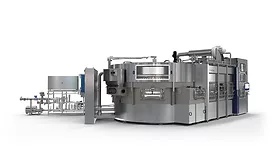

Automation in filling, seaming equipment addresses product safety issue

Read More

The pros of palletizers

Palletizers, depalletizers offer multitude of benefits for beverage brands

June 23, 2025

New facility planning, expansions aim to increase efficiency for beverage operations

Whether starting fresh or expanding, beverage operators have much to consider for facilities

May 27, 2025

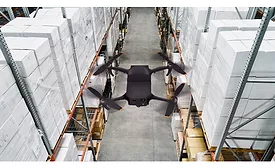

Record-setting ProMat exhibition connects manufacturers, supply chain

Automation, robotics and artificial intelligence dominate topics

May 9, 2025

Elevate your expertise in the beverage marketplace with unparalleled insights and connections.

Join thousands of beverage professionals today. Shouldn’t you know what they know?

JOIN NOW!Copyright ©2026. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing