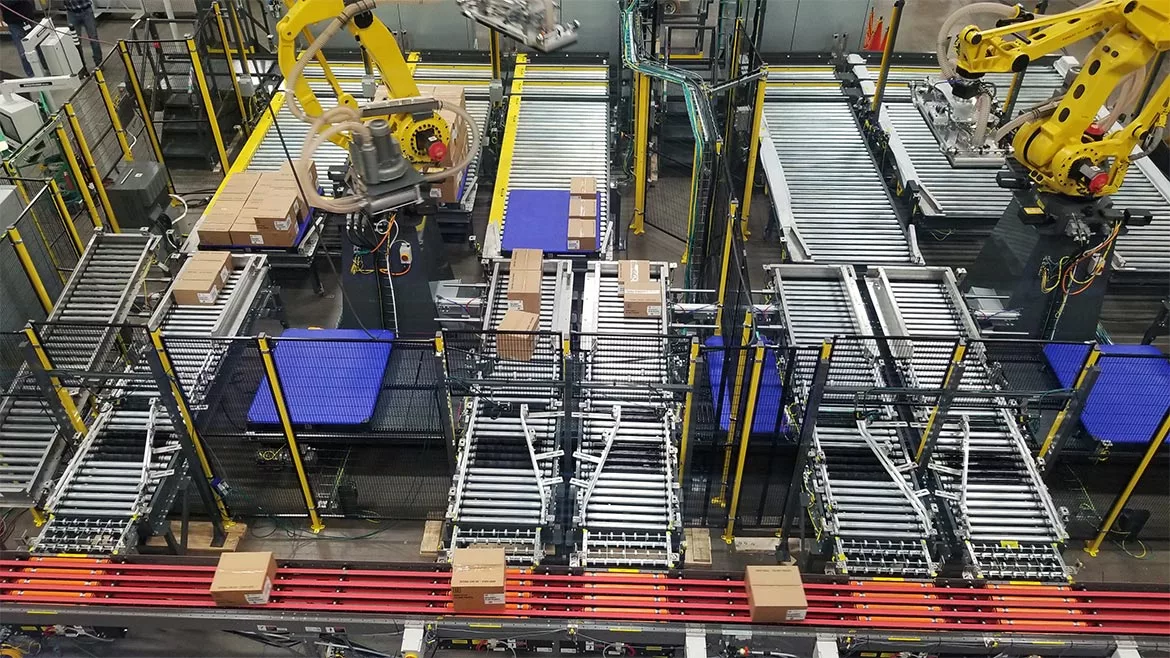

The pros of palletizers

Palletizers, depalletizers offer multitude of benefits for beverage brands

Image courtesy of BWIS

Beverage operations are consistently being tasked to do more and deliver more efficiency with those additional tasks. To support these increasing demands, operations managers are leaning more and more on new age technology and equipment.

When describing the beverage market demands for palletizers and depalletizers, Brandon Duba, solution consultant for Grand Rapids, Mich.-based Dematic, says that demand is continuing to rise as companies face growing operational pressures.

“Automated solutions offer speed, flexibility, and reliability, reducing manual labor, improving safety, and accommodating a wide range of product types,” he notes.

Mike Burns, director of product management at BWIS, Romeoville, Ill., also describes increased demand. He lists several key factors:

- Efficiency and productivity: Palletizers and depalletizers significantly enhance the efficiency and throughput of the beverage packaging processes.

- Labor cost reduction: By automating the palletizing and depalletizing processes, beverage companies can reduce labor costs and minimize the risk of human error/injuries.

- Product quality: These systems ensure that products are stacked and handled carefully, reducing the risk of damage during transportation and storage.

- Adaptability: Modern palletizers and depalletizers are highly adaptable, capable of handling different product sizes, shapes, materials, empty and full packages, etc.

- Market growth: The global market for palletizers and depalletizers is projected to grow significantly, driven by increasing automation in the food and beverage industry.

Ted Yeigh, palletizer division marketing manager at Columbia Machine Inc., Vancouver, Wash., depicts demand as very buoyant.

“There are a significant number of aging machines in the industry that are starting to be replaced, as well as several new production opportunities, especially with co-packers,” he states.

Jake Nieuwenhuis, manager of solutions engineering at Fairfield, N.J.-based DMW&H, says the market need for palletizers and depalletizers remains strong and is driven by the growing complexity of SKU management.

“As the number of product variations increases, manual palletization becomes more decision-intensive for workers,” Nieuwenhuis notes.

Similar to the other experts, Bill Stenger, senior vice president, sales at Swisslog Americas, Atlanta, notes that SKU proliferation is still happening, driven by the continuing evolution of the retail landscape and the changing demands and purchasing behaviors of consumers.

However, Stenger states that some companies and retailers are pulling back on the number of options they offer.

“It is less about the number of flavors and more about the packaging types,” he says. “You can now have 20 different packages for a product, depending on the retail outlet, region of the country, season, special promotions, etc.”

Stenger mentions that more retailers are wanting SKUs to come mixed with a variety of products.

“This demand is driving large beverage companies to expand to mixed-case palletizing,” he notes. “Mixed case palletizing, which involves strategically stacking different products onto a single pallet or cage, maximizes space and ensures stability during transportation, streamlining distribution, reducing handling time and accelerating store replenishment.”

With demand for mixed-case pallets growing, Stenger says more beverage companies are integrating robotic palletizing processes into their automation plans.

Impacts on the market

For original equipment manufacturers, though, the markets they serve and their trends have a great impact on next generation equipment. Dematic’s Duba mentions the host of beverage trends contributing to the need for these forms of machinery.

“Labor shortages and rising costs are forcing beverage distributors and manufacturers to adopt automation that reduces manual labor and ensures consistency,” he explains. “Palletizers and depalletizers help lower operating costs, support high-volume pallet cycles and accommodate the growing volume of SKUs by enabling compact, well-built pallets that maximize warehouse space and shipping efficiency.”

The rise of eCommerce and omnichannel fulfillment also has increased demand for smaller, custom-mixed pallets, Duba states, making scalable, high-speed palletizing and depalletizing systems essential for keeping pace.

BWIS’ Burns notes production output requirements, specifically in terms of labor shortages and automation.

“Manual palletizing/depalletizing can be challenging to hire for, as it is difficult work that can carry the risk of injury,” he says. “Therefore, companies are seeking to automate the process, making palletizing one of the fastest-growing machine segments. Another symptom of labor shortages is that customers value ease of operation, which automation can also support.”

Burns also points to sustainability initiatives.

“Producers can be more sustainable by reducing their use of packaging, including secondary packaging,” he suggests. “This make products more difficult to handle than they used to be. This is related to the trend below of evolving can shapes and sizes, which can make products increasingly challenging to handle.”

In general, Burns says there has been a shift to automation within the beverage industry, which supports greater adoption of automated palletizers and depalletizers.

Columbia Machine’s Yeigh simply says that there are several opportunities for high-speed machines and mixed-load, or rainbow load, palletizers.

DMW&H’s Nieuwenhuis explains that several factors are driving the need for advanced palletization, but notes that the most significant is the rapid growth in SKUs.

“We’re seeing an unprecedented increase in product variants, offering consumers more choices in sizes, flavors and options tailored to health-conscious preferences,” he says.

Swisslog’s Stenger says improving efficiency has become critical for retailers seeking to maintain margins in the face of changing distribution requirements.

“eCommerce hasn’t just created the need for direct-to-consumer (DTC) fulfillment, but along with other trends, has changed the amount of inventory retailers are keeping on store shelves and the frequency with which those shelves are restocked,” he notes.

Stenger also shares that building pallets manually is inefficient and results in pallets that increase workloads across the retail network.

“That has resulted in more retail distribution centers considering automating case picking and palletizing using the new generation of intelligent automation solutions now available,” he states. “For instance, BJ’s Wholesale Club recently announced it was working with Swisslog to build a new ambient distribution center that will feature automated pallet storage, robotics, case-handling equipment and mixed-case pallet building.”

As automation serves a bigger role in warehouse operations, there are many needs to be filled by palletizers and depalletizers. Dematic’s Duba shares his thoughts.

“As automation expands across warehouse operations, palletizers and depalletizers play a key role by integrating with other systems to enable end-to-end handling, from manufacturing lines to automated storage,” he says. “These solutions help build transport-ready pallets safely and efficiently, optimize warehouse space and support dynamic, multi-fulfillment models by automatically breaking down and rebuilding pallets as needed.”

Columbia Machine’s Yeigh says the “obvious one” as far as roles to be filled by palletizers is efficiency gains by having very high OEE and high throughput of automated palletizers and depalletizers.

“The less obvious role that modern palletizers can play is contributing to beverage industry producer’s sustainability initiatives,” he notes. “Modern palletizers are more energy efficient for sure, but specifically for Columbia Machine’s designs, we have worked very hard on developing solutions that allow our customers to reduce packaging materials and still protect the integrity of graphics and packaging through the palletizing process.”

Two examples of such technology include touchless turning via Columbia’s Soft Turn differential roll speed turners and Columbia’s servo controlled Starwheel turners, Yeigh adds.

DMW&H’s Nieuwenhuis says that, as labor challenges continue to grow, the demand for palletizing equipment is rising.

“Beyond addressing workforce shortages, automated palletizers and depalletizers offer faster, more efficient operations while improving worker ergonomics,” he states. “They eliminate the physical strain associated with manual palletizing — especially when building tall pallets, which are essential for maximizing truck space utilization. Automation ensures these pallets are consistently high, stable and safely constructed, something that can be difficult to achieve manually.”

Swisslog’s Stenger explains that automation solutions, including palletizers and depalletizers, can help enable companies to grow and expand to meet new business opportunities and demands more easily.

“They allow companies to grow with smaller capital requirements to expand, and can also be retro-fitted into existing warehousing, which reduces the need for new facilities or expansions,” he says.

As for addressing labor shortages, Dematic’s Duba says palletizers and depalletizers offset these shortages by automating repetitive, physically demanding tasks like building consistent pallets and unloading inbound cases.

“This reduces the need for manual labor, allows fewer workers to manager higher output and shifts key employees into higher-value roles,” he states. “Automation also improves safety by minimizing injury risks, which can lower workers’ compensation claims and reduce turnover in roles that are typically hard to fill.”

BWIS’ Burns echoes similar sentiments.

“Automated palletizing and depalletizing systems reduce labor costs, offer safety advantages and address threats to output from lack of human production resources,” he shares.

With minimum 98% OEE and easy to operate controls packages found on most conventional palletizers, Columbia Machine’s Yeigh says these machines “just work.” He notes that palletizers and depalletizers eliminate the need for undesirable, repetitive motion hand stacking of relatively heavy packages.

DMW&H’s Nieuwenhuis states that manual mixed palletizing is particularly challenging to staff because it requires workers to make smart, real-time decisions about product placement to ensure pallet stability.

“This means the role demands a higher level of skill to meet performance targets,” he explains. “From a productivity standpoint, automated palletizers and depalletizers can often double or even triple the throughput of manual processes. This increased efficiency reduces the overall labor requirement, helping to lower headcount while maintaining or improving output.”

Swisslog’s Stenger shares his thoughts regarding labor shortages, echoing the thoughts of the other experts.

“A number of companies are also using automation technology as a way to attract potential employees who are looking for opportunities to work with technology and want to be a part of a modern, enhanced work experience,” he says. “Finding people who are willing to spend their workdays manually case-picking in the warehouse is becoming increasingly difficult. So, anything that a grocer does to reduce the physical effort at the distribution center level will become a much bigger multiplier and make its stores even more efficient.”

Improvements in technology

The new age of palletizing equipment has come with advancements in technology.

“Modern palletizing equipment is becoming more agile and efficient, with advanced vision systems and robust software enabling stable mixed-SKU pallet builds,” Dematic’s Duba states. “As distributors ship a broader range of products to more destinations, custom pallet plans are increasingly common. Mixed-case palletizers streamline labor-intensive tasks and can follow multiple preprogrammed building guidelines.”

These systems also feature versatile end effectors that can quickly interchange without tools, he notes, some even operating simultaneously with multiple tools, such as top suction and side clamps, to handle varied product types.

BWIS’ Burns notes advancements such as dunnage sorting and handling at high and low levels, as well as human-machine interfaces (HMIs) that are improving the ease of operations and maintenance.

“Producers are leveraging robotics for palletizing and depalletizing versus legacy bulk palletizing and depalletizing systems,” he says.

Meanwhile, Columbia Machine’s Yeigh states that new electronics and more refined variable frequency drives (VFDs) allow for quicker and more precise movements leading to higher throughputs and easy recovery from downtime events.

DMW&H’s Nieuwenhuis shares his insights.

“Modern robotic palletizers now feature highly adaptable end effectors capable of handling a wide range of case sizes, shapes and materials,” he explains. “These tools often combine vacuum, mechanical and sensor-based gripping technologies, enabling precise and damage-free handling — even in mixed SKU environments.”

Nieuwenhuis also says that traditional static pick zones are being replaced by dynamic pick face systems that adjust in real time based on both product flow and availability.

“This is increasingly being enabled by smart robotics such as AMRs, which can reposition inventory and present cases to palletizers in the most efficient sequence,” he expresses. “This flexibility reduces cycle times, increases throughput and allows for seamless adaptation to changing product mixes.”

Dematic’s Duba feels that artificial intelligence (AI) will have significant influence on the palletizing and depalletizing market by enhancing load stability through AI-driven vision systems that detect errors, damage and improper stacking.

“These systems can also identify anomalies such as misaligned labels or irregular orientations,” he says. “AI will enable real-time optimization of pallet patterns, improving efficiency and maintaining load integrity. Looking ahead, AI will allow systems to learn and adapt, reducing the need for reconfiguration and minimizing programming requirements for new products.”

BWIS’ Burns anticipates AI will lead to improvements to machine monitoring and predictive maintenance.

Similarly, Columbia Machine’s Yeigh expects AI to assist in troubleshooting and machine recovery, more than it already does.

“This goes along with enhanced predictive maintenance and even the ability to integrate with a customer’s spare parts inventory and automated parts ordering capability if so desired,” he adds.

DMW&H’s Nieuwenhuis shares several ways AI could affect the palletizing and depalletizing market. He notes that AI is enabling smarter, more efficient operations.

“One of the key impacts is the development of advanced load-building algorithms,” he says. “These AI-driven systems can analyze product dimensions, weights and packaging constraints to create optimized pallet configurations that are not only larger, but also more stable. This leads to better space utilization and reduces the risk of product damage during transit.”

Additionally, Nieuwenhuis states that AI is enhancing the return on single pallet shipments by maximizing the number of units per pallet without compromising stability.

“This means fewer pallets are needed for the same volume of goods, lowering shipping costs and improving overall logistics efficiency,” he says. “In essence, AI is helping companies move beyond traditional, rule-based palletizing by introducing dynamic, data-driven decision-making that adapts to real-time variables — making operations more agile, cost-effective and scalable.”

Predicting the future

The experts share expectations for what is next for palletizers and depalletizers within the beverage market.

Dematic’s Duba expects equipment to become more modular, compact and collaborative.

“Future systems will increasingly feature scalable robotic solutions that safely operate alongside human workers, even in space-constrained environments,” he says. “These robots will be fully integrated with upstream and downstream systems — including labelers, fillers and warehouse management software (WMS) — for seamless facility-wide automation.”

Meanwhile, BWIS’ Burns predicts that the market will grow significantly, driven by the increasing need for efficiency and throughput.

“Market trends indicate a shift toward more intelligent, efficient and sustainable palletizing and depalletizing solutions in the beverage industry,” he states.

Columbia Machine’s Yeigh shares that the beverage industry can anticipate ultra-high-speed palletizers being introduced in the near future, specifically from the company itself.

“I believe we are just at the beginning of what AI and predictive maintenance can offer to both machinery manufacturers, but more importantly, to our beverage industry customers,” he says.

DMW&H’s Nieuwenhuis expects continued advancements in AI-driven pallet-building algorithms, enabling more efficient and stable load configurations tailored to a wider variety of product types.

“Additionally, the development of more sophisticated end-of-arm tooling will allow robotic systems to handle an even broader range of case sizes, shapes and packaging materials — enhancing flexibility and performance in high-mix beverage operations,” he says.

Swisslog’s Stenger anticipates advancements is the growth of connected and intelligent solutions.

“As solutions become more standardized, it becomes easier to leverage data (e.g., edge data, sensor data, product data, operational data) to make more insightful and effective operational decisions,” he notes. “This standardization is especially important for AI-enabled solutions. Maturity in solution design and software platforms will enable companies to leverage these technologies and the information that are more widely in use outside of our industry.”

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!