Home » Keywords: » can filling and seaming

Items Tagged with 'can filling and seaming'

ARTICLES

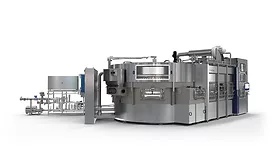

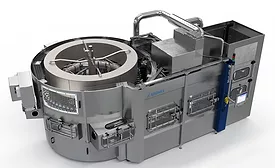

Automation in filling, seaming equipment addresses product safety issue

Read More

Changing consumer preferences call for updates in packaging equipment

Can filling and seaming equipment manufacturers prioritize flexibility, product safety

December 19, 2024

Packaging

Can filling, seaming equipment adapt to beverage trends

Popularity of cans, SKU proliferation driving innovation in filling equipment

December 20, 2023

Packaging Equipment

Can filling, seaming equipment supporting flexible operations, safe practices

Connectivity enables better guidance, adjustment in filling

December 19, 2022

Packaging Equipment

Flexibility vital for can filling and seaming equipment

Quality control, safety important on filling lines

December 30, 2021

Operations Perspective

Flexibility key to vital beverage packaging environment

Real-time changes impact manufacturing, packaging lines

December 29, 2021

Wilkens-Anderson enamel rater tests metal exposure

Machine measures metal exposure inside beverage cans

June 16, 2021

Oktober Can Seamers facilitates to-go packaging of alcohol drinks

Artfully designed branded cans market bars, restaurants

March 11, 2021

Wilkens-Anderson enamel rater tests metal exposure

Machine measures metal exposure inside beverage cans

March 9, 2021

Packaging Equipment

Demand for can packaging impacts filling, seaming equipment

December 22, 2020

Elevate your expertise in the beverage marketplace with unparalleled insights and connections.

Join thousands of beverage professionals today. Shouldn’t you know what they know?

JOIN NOW!Copyright ©2026. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing