Home » aluminum cans

Articles Tagged with ''aluminum cans''

Kids’ canned water brand encourages hydration, creativity

Read More

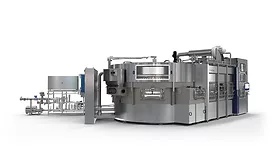

Advanced technology helps can filling, seaming equipment meet beverage market trends

Automation in filling, seaming equipment addresses product safety issue

December 18, 2025

Packaging helps Cheerwine Holiday Punch expand reach

Seasonal beverage debuts 12-packs of 12-ounce cans this season

November 12, 2025

Sustainability, convenience drive demand for aluminum packaging

Recycling efforts can support sourcing, supply chain issues impacting aluminum market

February 20, 2025

The Best Beverage Packages of 2024

Sustainability, pop culture partnerships motivate this year’s top selections

December 6, 2024

Elevate your expertise in the beverage marketplace with unparalleled insights and connections.

Join thousands of beverage professionals today. Shouldn’t you know what they know?

JOIN NOW!Copyright ©2026. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing