Filler technology hitting on all cylinders

Filling machines address beverage trends, flexibility and hygiene

|

As beverage-makers continue to develop new and exciting beverages, manufacturers of filling machines also continue to develop technology and products to accommodate the industry’s new directions.

Italy-based SIPA sees the importance of flexibility for beverage manufacturers. Through the years, it has advanced the technology of its products to address the demands for flexibility and fast changeover. “Flexibility is one of the key elements of the bottling lines of today and tomorrow,” the company says.

Recently, SIPA released a new series of volumetric filling valves: the Isotronic SC, for carbonated product applications, and the Unitronic SC, for still product filling. “These valves, replacing versions already present in the range, show new aspects that are absolutely state-of-the-art,” the company says. “Our goal [is] to go beyond the standard quality normally requested for this type of application.”

The Isotronic SC is an isobaric volumetric and electronic filling valve version and is suitable for filling liquids with or without gas into PET bottles, such as soft drinks, water and clear fruit juices, while the Unitronic SC is a gravitation volumetric and electronic filling valve version for products such as still water, juice, tea, energy drinks and milk in PET bottles.

“In the development of the new generation of valves, the aim was to achieve higher quality and levels of efficiency, while maintaining key features of the previous generation: simplicity and flexibility, high performance, ease of use and maintenance, and extreme cleanliness inside the system,” the company says.

However, the key features of its newest products are not the only thing SIPA sees driving the need for advancements with filling machines. “One of the major trends is to have more and more compact and integrated filling lines,” it says. “We are noticing that the market is following two main parallel directions: on the one side, extremely high-speed lines working with a single product and single size that are often realized with direct integration of the blow molder; on the other hand, [are] the rest of the lines with lower output handling many types of products and sizes.”

Particle variables

With some beverage-makers exploring juice drinks that contain pulp as well as sizable pieces of fruit, filling machine manufacturers have developed products to address this growing trend.

“The consumption of beverages including pulps or particles is becoming more and more popular and corresponds to a request for more natural and value-added products,” said Gero Von Stackleberg, product manager for sensitive products with Sidel Group, in a statement.

Swiss company Sidel addresses this need with its new Veloce ISD hot filler with integrated slurry dosing. The Veloce ISD is designed to fill beverages such as pulpy juices, flavored waters with fruit pieces, Chinese specialty drinks, aloe vera and coconut-based drinks in PET containers. It can dose particles up to 10-by-10-by-10 mm. in size and with particle quantity concentration ranges from 10 ml. to 200 ml., depending on the recipe and bottle size, the company says.

The Veloce ISD in-line filler features double stage filling, beginning with a dosage of particles in pumpable slurry, followed by filling the bottle with liquid. Sidel says the accurate dosage from the Veloce guarantees that a steady and precise quantity of particles is administered in the final beverage product. The filler guarantees the quality of the filled beverage and maintains the physical integrity of the particles, it adds.

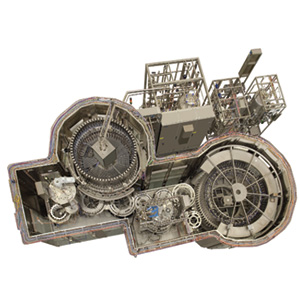

The Monobloc Veloce ISD machine handles plastic bottles by the neck and is composed of a rinser, doser, filler and capper. The company also ensures that during the capping process, no microbiological risk can occur between the neck thread and the cap.

Safety first

Hygienic practices were front of mind for Dormund, Germany-based KHS and its new Innofill Glass filling system.

“The chief feature of the new Innofill Glass system is the consistent implementation of the hygienic design concept,” the company said in a statement. “The optimization thereof results in a range of additional benefits, such as consumer protection thanks to increased product safety, and cost reductions through simpler cleaning and maintenance.”

No electrical elements, pilot valves and control hoses in the filling valve are in the hygiene area, it says.

The glass bottle filling machines provide a basis for various electronic KHS filling systems that can be tailored to suit the individual criteria of specific filling methods. The company’s first release on this platform was the Innofill DRS-ZMS pressure filling system for the beer industry.

Innofill Glass systems were designed with no corners and edges but with curves and slopes, enabling a rapid runoff of liquids. It also features a bottle transfer frame that connects the stars and capper modules using open pipes with no flanges, the company says.

Efficiency also was important with the system. Drives with torque motors have an efficiency of 96 percent, KHS says. BI

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!