Packaging Equipment

Automation in filling, seaming equipment addresses product safety issue

Read More

Plastic bottle manufacturers address energy reductions, lightweighting

Government regulations, digitalization have growing influence on plastic bottle equipment

October 21, 2025

Efficiency drives labeling equipment

Beverage-makers seek machinery that supports diverse portfolios

August 26, 2025

Industry trends task coding technology to meet growing list

Sustainability, automation prompt innovation for coding, marking suppliers

July 23, 2025

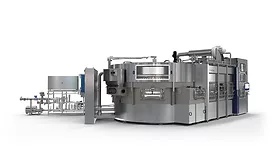

Filler technology has required recent innovations, updates to keep up with trends

SKU proliferation, premiumization and sustainability all impacting filler technology

March 27, 2025

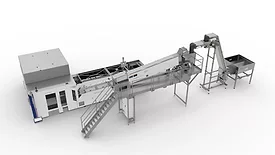

The case for case packers and wrappers

Beverage-makers utilize case packers, wrappers to support SKU increases

February 14, 2025

Changing consumer preferences call for updates in packaging equipment

Can filling and seaming equipment manufacturers prioritize flexibility, product safety

December 19, 2024

Plastic bottle manufacturers help beverage operations tackle sustainability goals

Changeover efficacy vital to accommodate new products, packaging

October 24, 2024

Elevate your expertise in the beverage marketplace with unparalleled insights and connections.

Join thousands of beverage professionals today. Shouldn’t you know what they know?

JOIN NOW!Copyright ©2026. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing