Home » palletizers

Articles Tagged with ''palletizers''

Operations

Automated palletizer systems optimize manufacturing, save time

Increased efficiency, space utilization improve operations

June 26, 2020

Supplier's News

Spa Springs provides co-packing, labeling and palletizing services for beverage companies

April 12, 2020

Emerson, Arrowhead Systems create machine health monitoring solution

Real-time solution brings data together for accessibility, visualization and analysis

December 11, 2019

Universal Robots presented comprehensive portfolio at Pack Expo

Company launched new rapid response program, Service360 Now

October 11, 2019

eCommerce trends impact palletizing market

Beverage packaging options also influence palletizing solutions

August 2, 2019

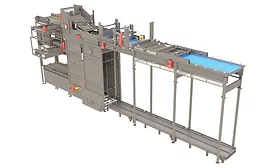

Alvey palletizer handles diverse packaging types

Palletizer proves real-time monitoring, diagnostics to boost reliability

January 16, 2019

Palletizers, depalletizers, backbone to packaging operations

Flexibility, speed and safety paramount for palletizing equipment

July 23, 2018

FTA drum-handling unit assists with loading and unloading steel drums

‘Parrot-Beak’ clamping system works with standard lift trucks

May 22, 2018

Palletizing equipment drives beverage operations

Suppliers release new high-speed palletizers

July 14, 2017

Elevate your expertise in the beverage marketplace with unparalleled insights and connections.

Join thousands of beverage professionals today. Shouldn’t you know what they know?

JOIN NOW!Copyright ©2026. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing