Operations

Reusable container systems help reduce companies’ carbon footprint

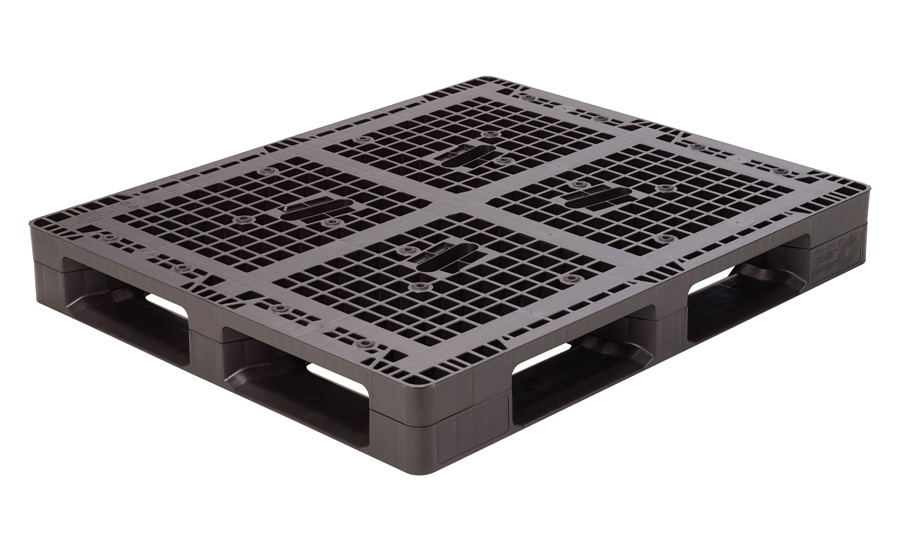

Plastic pallets helps reduce CO2 emission during transportation

Image courtesy of Getty Images

When it comes to the sustainable use of plastic, often what comes to mind is recycling it. However, as the packaging sector is one of the largest consumers of plastics, this material also is helping to reduce the carbon footprint of the industry by reducing carbon dioxide emissions during transportation.

“We have seen, through data proved by ORBIS RPM [reusable packaging management], that customers have plastic packaging in their supply chain that is 20 years old and has traveled 100 plus loops through the supply chain,” says Christopher Wood, pallet product manager at ORBIS Corp., Oconomowoc, Wis. “This sustainability of plastic packaging compared to a higher damage rate on wood packaging has allowed our customers to be more efficient for their operations and sustainable for the environment.”

Additionally, plastic packaging offers durability, ease of use and ease of cleaning, making it more cost-efficient than single-use packaging, experts note.

Wood explains that ORBIS RPM works with its customers to sort, clean and manage assets to ensure that they have the right amount of packaging to keep them running efficiently.

Moreover, utilizing reusable packaging systems helps eliminate the repeated need to manufacture single-use packaging, which can save companies the cost of raw material, energy and labor, the company notes.

Image courtesy of ORBIS Corp.

As companies drive global sustainability through operations, reusable packaging such as reusable plastic containers, pallets, dunnage and bulk systems improve product flow along the supply chain, it adds. This not only helps reduce costs and enhances profitability, but perhaps most importantly, helps a company significantly reduce its carbon footprint, it notes.

In September, ORBIS Corp. added the new Universal Container Pallet (UCP) to its suite of reusable plastic pallet offerings in Latin America. Engineered to protect and transport foodservice products with ease, the 44-inch-by-56-inch, two-piece snap-designed injection foam UCP optimizes daily operations in the food and beverage industry, the company says.

“The new UCP, designed with durability and sustainability in mind, will bring efficiency to food and beverage distribution throughout Latin America,” said José Ramón Ramírez, director de ventas of ORBIS Corp. Latin America, in a statement. “We’re proud to offer companies complete food and beverage systems to optimize their supply chain for sustainability, while protecting and transporting their products. The introduction of the UCP further solidifies our leadership in reusable packaging as we grow our footprint in the LATAM region.”

Additionally, the UCP is compatible with palletizers, depalletizers, automatic strapping/banding systems, conveyors and pallet washing systems, solidifying its place in ORBIS’ product lineup as a complete solution, the company notes. With the additional option of adding advanced radio-frequency identification (RFID) or barcode configurations, this product can help provide visibility into where products are located, preventing loss and increasing productivity, it adds.

More efficiencies

Experts note that as the COVID-19 pandemic has impacted manufacturing across the globe, many companies are relying, more than ever, on reusable packaging systems to track individual assets like pallets, trays and other reusable transport containers in real-time with RFID.

Wood notes that ORBIS’ RFID and BLE (blue low energy) are being used in specific situations to do more in-depth tracking of an asset’s data, allowing customers to see their asset’s path through the supply chain, creating a more efficient supply chain for the end user.

Image courtesy of ORBIS Corp.

“Currently the largest impact is in the aluminum can expansion,” Wood says. “The shortage of aluminum beverage cans in the U.S. has caused expansion in the inbound markets and, therefore, increased the amount of reusable packaging needed in the market to deliver cans from the can manufacturer to the fillers to distribution to the end user.

“It is more important than ever, as the inbound market continues to expand, for customers to track their assets in the supply chain to get as many uses as possible,” he continues. “It allows customers to be more sustainable and keeps customers from experiencing any downtime in manufacturing.”

As the pandemic has shined a light on the need to find efficiencies and reduce unnecessary cost for businesses to not only survive, but also thrive, new strategies are intensifying efforts for resource-efficient supply chains, experts note.

In November, Pullach im Isartal, Germany-based IFCO, a leading provider of reusable plastic containers (RPCs) for fresh food packaging, presented its comprehensive ESG (Environment Social Governance) 2025 strategy to thrive in the circular economy.

The main objectives include combating climate change, embracing diversity and inclusion as well as reducing food waste and single-use packaging, according to IFCO.

“We have already achieved considerable success with our measures to be more environmentally friendly. At the same time, we acknowledge that it is time for further action,” said Micheal Pooley, CEO at IFCO, in a statement. “Together with our partners, we are working every day to make our business model even more sustainable. Our new ESG strategy helps us to fulfill our purpose to make fresh grocery supply chains sustainable and have a meaningful positive impact on our planet and society.”

“It is more important than ever, as the inbound market continues to expand, for customers to track their assets in the supply chain to get as many uses as possible. It allows customers to be more sustainable and keeps customers from experiencing any downtime in manufacturing.”

-Christopher Wood, pallet product manager at ORBIS Corp.

As IFCO’s business model fosters the principles of circular economy — a tenet in place since the company’s founding almost 30 years ago — its European Lift-Lock range of RPCs was awarded the Cradle to Cradle Certified Silver certification, the company says. IFCO RPCs are reused up to 120 times, cleaned, disinfected and granulated at the end of their lifecycle to produce new containers, it adds.

Suppliers also are highlighting the lifecycle length that accompanies reusable container systems.

According to a recent study, ORBIS Corp. validated that its 40-inch-by-48-inch Odyssey plastic pallet has approximately 36 times the lifespan of a 40-inch-by-48-inch whitewood stringer pallet. “Researchers from the Virginia Tech Center for Packaging and Unit Load Design used the center’s FasTrack lifecycle analysis to compare relative durability,” the company said in a statement.

The FasTrack lifecycle analysis simulated rough handling of palletized unit loads, using a multi-step handling sequence. In testing, the Odyssey plastic pallet completed the sequence 400 cycles without failure, while the wood pallet’s average failure occurred after 11 cycles, according to ORBIS Corp.

“In completing this testing, we wanted to quantify the life and durability of plastic pallets to help companies understand the long-term cost savings associated with reusable plastic pallets,” said Achim Banik, ORBIS’ lead engineer. “The FasTrack lifecycle analysis confirms just one of the many advantages plastic pallets have over wood. More companies are transitioning to plastic pallets not only for their durability, but also for their uniform design for seamless integration with automated systems, cleanability and sustainable benefits.”

As manufacturers are evolving to meet the distribution needs of 2022 and beyond, more conversions from wood and fiber layer pads onto plastic packaging will enable supply chains to be more efficient and sustainable, ORBIS’ Wood says.

“There is still a lot of wood and fiber in supply chains, from manufacturers to the end users, causing issues with sustainability and downtime on the operations,” he concludes.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!