Plant Focus

Anheuser-Busch invests $16M in Los Angeles brewery

Investment will help increase facility’s capabilities and capacity

September 26, 2024

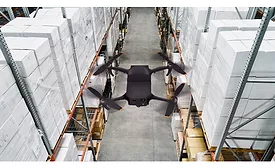

Automation, data collection make robotics more appealing to beverage warehouses

Business case highlights benefits of robotic investment

September 24, 2024

Proactive solutions

Voice picking technology brings efficiency to fast-paced beverage operations

Voice-directed solutions with integrated AI offers advantages in beverage market

September 19, 2024

Elevate your expertise in the beverage marketplace with unparalleled insights and connections.

Join thousands of beverage professionals today. Shouldn’t you know what they know?

JOIN NOW!Copyright ©2026. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing