JBT Corp releases system that reduces retort water volume by 45 percent

Hybrid layer pad reduces breakage of glass containers

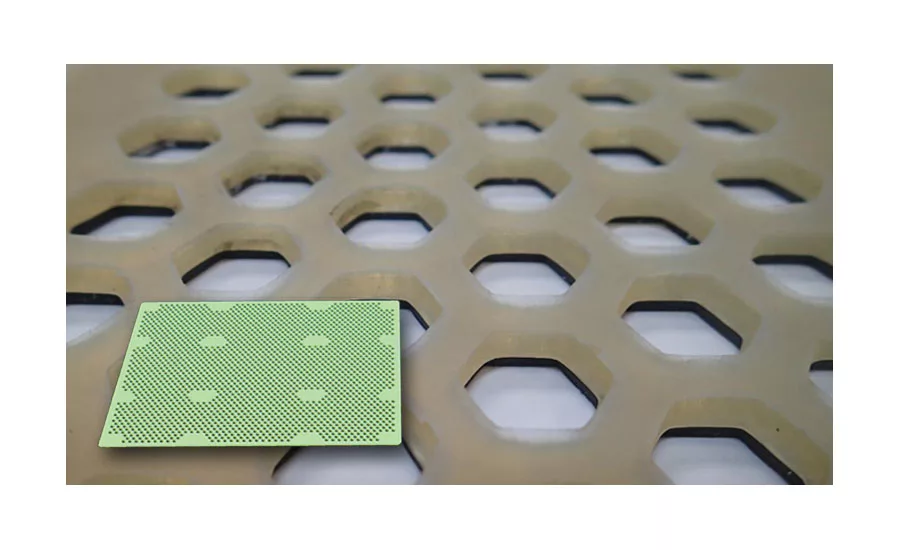

JBT Corp. recently launched two new solutions: the Low Energy Suction System (LESS) for static retorts, which can deliver significant energy savings by reducing retort water volume by up to 45 percent; and the Hybrid Layer Pad, a unique-to-market system developed for glass bottles, especially coffee drinks, during sterilization. Designed for static 1800mm Steam Water Spray retorts, LESS is a bolt-on solution that saves energy by decreasing heating and cooling costs through the use and re-use of a more limited volume of water, the company says. A special distributed suction circulates the water while maintaining a high enough level to avoid complications, such as pump cavitation, while improving the handling of sensitive packages. The Hybrid Layer Pad works by securely holding irregularly shaped glass containers during rocking or end-over-end agitation so the packaging looks as good after the process as when it first entered the retort. It also works well with glass bottles of varying heights that have lids with lithograph prints that can rub off on contact with metal. To overcome this challenge, the pad features a spongy rubber material combined with a stiff metal base that protects the sensitive lithograph cap from damage and when the layer pad is compressed on top of the bottles, securely hold them in place, regardless of differences in height. The layer pad, which has been in development for several years, potentially eliminates the risk of breakage or damaged containers that can’t be sold, the company says.

JBT Corp.

400 Fairway Ave.

Lakeland, Fla. 33801

863/683-5411

jbtc.com

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!