Suppliers release products for beverage packaging and storing operations

New innovations available for filling and printing operations

Filling it right

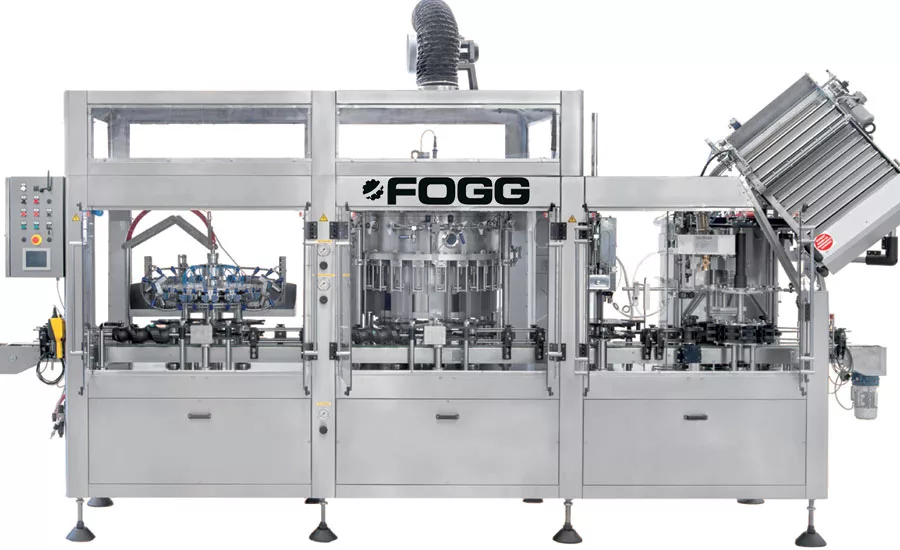

A supplier of liquid rotary filling systems, Fogg Co. introduced its carbonated filler machine that features double pre-evacuation with intermediate carbon dioxide purging (flushing) before filling. The combination of an analogue probe, for monitoring the filling tank level, and a modulating valve ensures gentle handling of the product and better control of undesired foaming, the company says. The machine is equipped to fill 355-ml (12-ounce) glass bottles at rates of 25 to 40 bottles a minute. It also caps the bottles with a metal crown cap that has been sorted by the attached automatic vibrating hopper, it adds. The machine can be adjusted to various specifications and fills anything from still or carbonated water to beer and wine.

Fogg Co., 3455 John F. Donnelly Drive, Holland, Mich. 49424; 616/786-3644; foggfiller.com.

Packaging innovation

At All4Pack 2016, Nov. 14-16, in Paris, KHS GmbH will showcase its digitally printed PET bottles and its new Direct Print Powered by KHS innovation, which enables brand owners to quickly launch new bottle decorations. Based on specially developed low-migration LED-UV cure inks, Direct Print combines a secure cloud-based artworks management platform with off-site sample printing for design and approvals. The technology also leverages image variability for future PET bottling lines, it says. KHS offers a variety of filling and packaging systems, including the KHS Innopack Kisters DP, which provides flexibility for packaging and palletizing, and the KHS InnoPET TriBlock, which incorporates a stretch blow molder, labeler and filler while providing consistent neck handling for the processing of lightweight PET bottles, it says.

KHS USA, 880 Bahcall Court, Waukesha, Wis. 53186; 262/797-7200; khs.com.

Driving digital printing

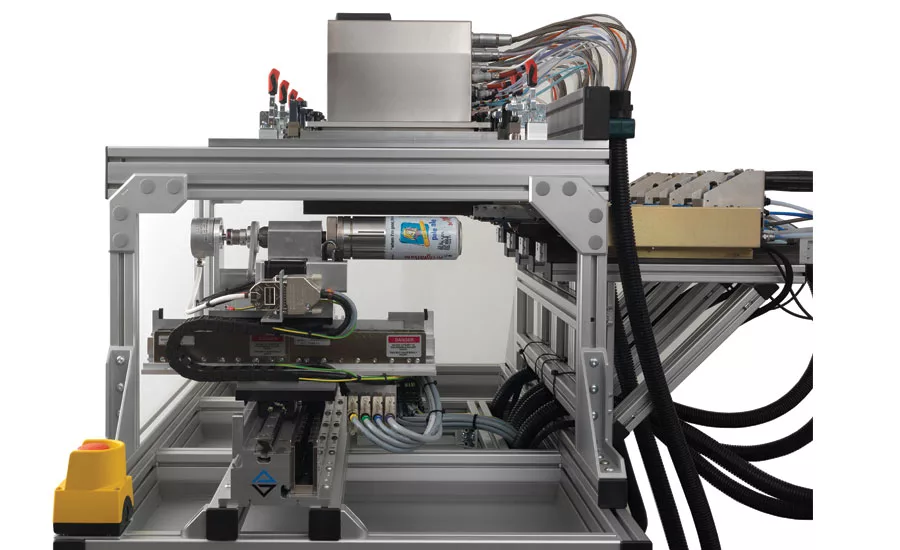

Tonejet Ltd. offers its Digital Printing Engine that provides direct-to-can digital printing, which is particularly useful in the craft beer market that typically requires short- to medium-print runs, the company says. The high-resolution digital-imaging process allows different images to be printed without the need to stop the production line, change printing plates or change printing inks, it adds. Designed with an electrostatic drop on-demand deposition technology, the print engine enables high-quality print on a wide variety of substrates at high speeds. It also features the ability to deposit concentrated pigmented inks and to continuously vary the droplet volume, without impacting throughput, the company says. Additionally, Tonejet’s technology also helps facilitate customized print runs for event- and location-specific products, premium products, and special market promotions, it adds. Other features include Tonejet’s proprietary nozzle-less print heads, an electronic and ink management system, data control and image management, and automated print head and ink system maintenance, it adds.

Tonejet Ltd., Melbourn Science Park, Melbourn, Hertfordshire, SG8 6EE, United Kingdom; +011/44-20-1763-266566; tonejet.com.

Safety first

Charles Ross & Son Co. announced that its tumble blenders now come equipped with an electro-magnetic brake to provide an added safety feature, the company says. A safety gate around the blender also prevents operation of the tumbling vessel while the brake motor allows the tumbling V-cone or double-cone vessel to safely decelerate to a complete stop at the proper upright position, it adds. Designed for mixing products with bulk densities as much as 150 pounds, Ross’s 50-cubic-foot V-Cone Tumble Blender gently blends free-flowing solids and a high-speed intensifier bar breaks up lumps and agglomerates, if necessary. Additionally, the intensifier bar includes multiple spray nozzles for introducing minor liquid ingredients to the batch. The tumbling vessel is driven by a 30-horsepower brake motor, while the intensifier bar/chopper is driven by a 15-horsepower motor, it adds. Available in sizes from 0.25 to 100 cubic feet, Ross Tumble Blenders are available with such options as vacuum capability, heavy-duty design for high-density applications, a heating/cooling jacket, explosion-proof motors and PLC controls, the company says.

Charles Ross & Son Co., 710 Old Willets Path, Hauppauge, N.Y. 11788; 800/243-7677; mixers.com.

High-speed snapshot

Fastec Imaging offers its IL5 high-speed 5MP cameras to help beverage manufacturers record and analyze fast-moving production lines and provide easier troubleshooting via its slow-motion replays, it says. The four models boast crisp, clean videos that can record more than 3,200 frames per second (fps) with a high-quality video graphics array and more than 18,000 fps at smaller resolutions, it adds. Images also can be saved to an SSD or SD card while recording high-speed bursts of thousands of images at a time, it says. Built for flexibility and ease of use, the Fastec IL5 camera can be controlled by Gigabit Ethernet via Fastec FasMotion software on a PC or Mac or through a built-in web interface with a web browser on a PC, Mac, tablet or smartphone, it adds. The camera records, pauses and follows the action with the ability to append additional footage and also can record at high speed and resolution for extended minutes or for hours at reduced resolutions, it adds.

Fastec Imaging, 17150 Via Del Campo, Suite 301, San Diego, Calif. 92119; 858/592-2342; fastecimaging.com.

Rugged power

UniCarriers Americas Corp. offers new FK Series forklifts that provide as much as 7,000 pounds of capacity and are powered by low-emission Advanced Turbo Diesel engines, which require no regeneration time, it says. With capacity options between 4,000 and 7,000 pounds, the new EPA Tier 4, CARB-certified diesel industrial engines feature electronically controlled fuel injection, cooled exhaust gas recirculation and a diesel oxidation catalyst to provide low-emission levels and near elimination of particulate matter, it adds. Additionally, no regeneration or “burn off” time is required, resulting in more uptime and increased productivity. The series includes full-suspension seats with lumbar-support adjustments and non-cinching seatbelts for operator comfort and support. The series’ Operator Presence System automatically locks lift-and-tilt operations when the operator leaves the seat and includes audible and visual warnings if the seat belt is not engaged or if the parking brake has not been applied prior to the operator exiting the compartment, it adds. Other features include a computer-controlled electronic engine system with common-rail fuel injection and a multifunctional LCD with onboard diagnostics and programmable service reminders.

UniCarriers Americas Corp., 240 N. Prospect St., Marengo, Ill. 60152; 815/568.2563; unicarriersamericas.com.

Holding out for a hero

SIG Combibloc offers a secondary packaging solution for tall, slim beverage cartons that are not the same height as the carton-packs, the company says. The new HERO tray ensures carton-packs are evenly stacked and safely protected during transport. The tray also can be used to present the product on retail store shelves. The cost-effective solution provides shallow trays at the front to ensure the front communication panel is visible, while the back of the tray, which is the same height as the carton-packs, ensures that the carton packs are not crushed during transport, according to the company. The tray formation of two-by-four carton-packs (stacked in five layers) enables 800 1-liter carton-packs to fit on a Euro pallet without overhang, a unique solution in the market, it adds. The HERO trays are being used in German convenience stores, with further market launches planned.

SIG Combibloc Inc., 2501 Seaport Drive, Chester, Pa., 19013; 610/546-4200; sig.biz.

Software support

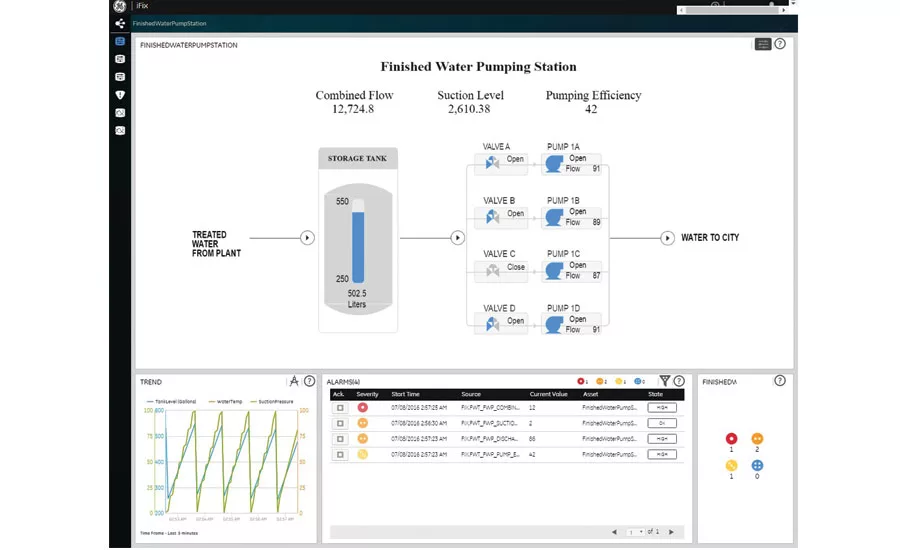

GE Digital unveiled a new generation of its automation software portfolio. The new GE HMI/SCADA software offers comprehensive, best-in-class monitoring and visualization capabilities, as well as work-process management, analytics and mobility, the company says. Based on the International Society of Automation’s high-performance design principles, the fourth-generation software features task-management capabilities and a context-rich human machine interface (HMI) that changes as the user moves through the system, while the navigation, which is derived from a structured asset model, guides operators with the most-informed view of the problem or task at hand, it adds. New Workflow 2.5 and Mobile 2.0 solutions extend the capabilities of Decision Support HMI/SCADA further, helping companies achieve their critical business outcomes, the company says.

GE Digital, 2623 Camino Ramon, San Ramon, Calif. 94583; 925/242-6200; ge.com/digital.

Coming through in a clutch

Force Control Industries Inc. introduced Posidyne long coupled C-Face clutch brakes for high-cycle applications of 50 to 300 cycles per minute (cpm). The clutch brakes reduce motor shaft and keyway damage, which is common in high-cycle count applications, the company says. When indexing with a clutch brake, each clutch engagement transfers a torque spike to the connection between the motor shaft and the input shaft of the clutch brake. The shrink-fitted C-Face offers a 360-degree connection that transfers the torque through the shaft, not just the key, which prevents the continuous, severe hammering on the shaft connection, it adds. The long coupled Posidyne clutch brake also offers the simplicity of C-Face mounting and a tight-fitting coupling. It also features oil shear technology that allows rapid and precise stopping, starting, reversing, speed change and positioning, it adds. With cycle rates as high as 300 cpm, the motion control device also offers production times as much as 10 times longer than traditional (dry) clutch/brakes, reduced downtime, no adjustments, minimal maintenance and a multi-year service life, it adds. The Posidyne clutch brake is available in multiple sizes, from ½- to 350-horsepower (99- to 79,000-pounds), with cooling options, control logic and mounting arrangements to simplify and speed installation, it says.

Force Control Industries Inc., 3660 Dixie Highway, Fairfield, Ohio 45014; 513/868-0900; forcecontrol.com.

Nature’s Way is now USHydrations

Nature’s Way Purewater Systems announced that it is changing its name to USHydrations to meet ever-increasing market demand. The premier beverage contract manufacturer, which has doubled in size during the past three years, serves a variety of global brands with custom formulation and co-packing services.

“Our new name — USHydrations — better reflects our expanded operations, high-volume capabilities, commitment to our clients, high-premium mountain spring water and what we actually provide our clients,” said Prashant Shitut, president and chief operating officer, in a statement. “We have been in business for more than 20 years and have grown with the industry. What have remained constant are our experienced management team, our high-level certifications, our rigorous testing and quality control, and our excellent customer service.”

USHydrations offers spring, purified, carbonated and flavored premier water products for prominent regional, national and global brands. Its mountain spring water is sourced from two spring sites, each within 25 miles from the 300,000-square-foot production and warehousing facility, which sits on a 50-acre site, the company says. Purified water is sourced from a reservoir located in the Pennsylvania countryside.

Shekhar Patel, director of innovation and quality, added: “Our commitment to our clients’ brands is reflected in a quality systems approach where people, processes, technology and infrastructure come together to provide safe products that meet or exceed quality benchmarks. In addition, we follow a systematic risk-based approach to meeting [current good manufacturing practice] CGMP requirements.”

USHydrations maintains a Level 3 Safe Quality Food (SQF) Certification, the American Institute of Baking (AIB) International Certification, the Food Marketing Institute Certification, as well as Orthodox Union and U.S. Army certifications.

The company has made significant capital investments and technological upgrades in order to remain at the forefront of the highly competitive beverage industry, it says. Also, it has heavily invested in its in-house testing laboratory in an effort to make it one of the most scientifically advanced in the industry, it adds.

Located in northeast Pennsylvania with easy access to major interstates, USHydrations is accessible to more than 100 million consumers, it says. The company’s production processing options include cold fill, mineral injection, ability to fill custom bottle designs, pressure-sensitive and roll-fed (glue) labeling equipment, as well as a variety of diverse packaging options.

“As the beverage industry continues its evolution, USHydrations is positioned and poised to help both existing and new customers achieve their goals,” Shitut added.

USHydrations, 164 Commerce Road, Pittston, Pa. 18640; 570/655-7755, ext. 228; ushydrations.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!