Packaging trends drive flexibility in case packers and wrappers

Beverage equipment suppliers offer flexible, fast case packers and wrappers

After being carefully set in a line, when a single domino is knocked over into the next, the entire line will fall. Similar to the cascading effect of falling dominos, changes within the front-end of beverage operations often will cascade through the manufacturing facility all the way to the end-of-line operations, even to case packing and wrapping.

Case packers and wrappers are a part of one end-of-line process that has felt the effects of the changing beverage industry. Whether it’s the growing numbers of SKUs or changes in packaging materials, suppliers of this equipment have had to innovate their offerings to provide solutions to beverage manufacturers.

Quick to change

Like other processes within the beverage industry, case packing and wrapping machinery must meet the demands for flexibility and speed, experts say. According to Jonathan Jenkins, applications engineering manager at Brewerton, N.Y.-based Schneider Packaging Equipment, the consistent evolution of packaging has required more flexibility from case packers and wrappers.

“Consumer demands have required beverage case packers to become more flexible to accommodate varying product shapes, sizes and capacities,” he says. “This ultimately leads to more opportunities for packaging companies.”

He adds that flexibility is one of the most important factors for case packers and wrappers. “Equipment should have the ability to accommodate current products and adapt to future needs,” he says, adding that overall ease-of-use is important, too.

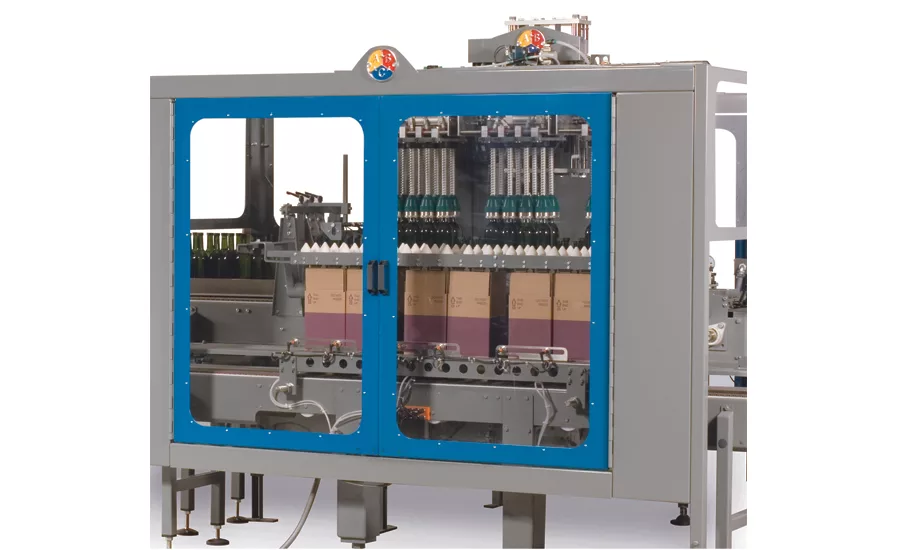

Bryan Sinicrope, vice president of sales and marketing for A-B-C Packaging Machine Corp. (A-B-C), Tarpon Spring, Fla., echoes similar sentiments. “It’s more important than ever before to offer highly flexible equipment to help processors react to changing market demands,” he says. “It is important for packers to be flexible and offer quick changeover, as beverage processors are packaging in more bottle sizes and styles. This is a change from the past where dedicated lines ran the same container every day.”

Jenkins notes that manufacturers require case packers and wrappers that can handle various products and case sizes. “Machines must feature increased flexibility right out of the box, so operators can maximize their packaging potential from the moment the machine hits the plant floor,” he says. “Consumer packaged goods companies want freedom to create new designs and drive sales through various marketing initiatives. Production must be able to accommodate these changes.”

Environmental concerns also are contributing to flexibility demands, particularly in relation to lightweighting. “As more sustainable measures are incorporated into beverage packaging, more challenges arise for case packing,” Jenkins explains. “Lightweighting, which includes using lighter materials or less packaging in general, creates challenges because gravity is often used to drop products in a case. As a result, additional design considerations are necessary.”

He notes that Schneider packing machines are designed to maintain control over the product at all times. “More control means less margin of error,” he says. Schneider offers a high-speed horizontal case packer that accommodates all case styles at 30 cases a minute, Jenkins adds. The company also offers vertical-loading, monoblock case packers that specifically are built to pack gable-top cartons.

He adds that bottle packaging trends are showing an increased use of shrink-wrap in place of corrugated cardboard. “This saves on costs, but ultimately leaves the product more vulnerable to mishandling during transit,” Jenkins says.

A-B-C’s Sinicrope also highlights the challenges sustainable beverage containers can present. “Lightweighting has affected case packing as plastic bottles are not as strong and in some cases can’t be stacked without support,” he says. “This impacts the secondary packaging, and necessitates a review of the packaging, palletizing and warehousing standards to make sure they are designed to ensure the package integrity. Likewise, with glass containers, they require gentle handling during packaging to ensure product integrity and performance throughout distribution and at the end-user.”

He notes that robotic offerings are highly flexible and can be more cost effective than a high-speed wraparound case packer.

The company offers its Model 101 Pick and Place Case Packer, which provides smooth and gentle product handling to maintain product integrity, it says. During case packing, synchronized operation also keeps containers under complete control, and PLC electronics implement all operating commands to ensure accurate placement. It also offers instant response to changing production conditions, the company adds.

Norcross, Ga.-based Gebo Cermex’s Key Market Director of Non Alcoholic Beverage Jean-Marie Vasseur also notes the effects of lightweighting and other sustainability concerns. “Today, we do not supply only a machine. We propose a complete solution including a performant infeed and collating system being able to manage lightweighted bottles,” he explains. “Our automation platform uses new servo-driven technology, which helps us reduce electric power consumption significantly.”

He also highlights the importance of speed for case packers and wrappers in the beverage industry. “End-of-line, globally, is still under a huge trend of automation to reach higher line speeds, increase productivity of the line (if done manually before) and reduction of musculoskeletal disorders for the operators,” he says.

Vasseur adds that Gebo Cermex offers a range of case packing and wrapping solutions with speeds as fast as 120 cycles a minute for bottles and cans.

Schneider’s Jenkins notes that as manufacturers require efficient operations, automatic changeovers can provide one solution. “[Automatic changeover] requires less time, fewer parts and less labor to switch from one product to another,” he says.

Fulfilling the need for speed, Douglas Machine Inc., Alexandria, Minn., launched its Axiom ARC Continuous Motion Case Packer in May 2015, which caters to the coffee creamer market. The case packer meets needs for high line-speeds when packaging coffee creamers for large outlet retailers in six-packs at 98 cases a minute, the company says. The machine utilizes a five-paddle loader, Slipstream pinless metering technology and an enhanced blank setup design, it adds.

Easily integrated

As new products constantly are launched, beverage manufacturers and warehouse operators continue to seek out the most efficient use of their warehouse space, and equipment suppliers have developed machinery that accommodates both efficient use of time and space as well as flexibility. This has resulted in combination end-of-line machinery.

“Customers are looking for an overall [total cost of ownership] TCO reduction with high-efficiency and flexible systems, with automatic changeover and manpower optimization thanks to a compact end-of-line layout,” Gebo Cermex’s Vasseur says.

He highlights the company’s VersaBloc. “VersaBloc combines the technology of shrink-wrapping and palletizing to form a block encompassing all end-of-line operations,” he says.

He notes that the combination machine offers several benefits, including single operator control of the entire packaging area from a single booth. Like many combination machines, it also offers a compact size that reduces the amount of floor space needed for end-of-line operations.

Noting the benefits of combination machines, in February 2015, Douglas Machine announced that its intermittent-motion Invex IM wraparound case/tray packer and VS-25 shrink-wrapper now are fully integrated. The integrated case-packer-and-shrink-wrapper creates a compact and economic solution for those seeking the flexibility of a full case, pack or tray with shrink wrap for mid-range applications, the company says. The integrated machine also can pack as many as 25 packages a minute within a single platform and is designed for quick changeover, it adds.

In April 2015, the company released its TriVex RLi, a top-load case packer with integrated erect, load and seal features. The machine features a small footprint by utilizing robotic staging and loading, which eliminates the traditional cross-push section, thus saving production floor space, the company says. The integrated platform erects cases, loads cartons in multi-tiers, and then seals and discharges, it adds.

Most recently, the company launched a single-cell top-load case packer, which integrates several steps into one case packer, saving floor space. In December 2015, it expanded its offerings with fully integrated top-load case packing machines for wine bottles. Integrated single-cell solutions include case erecting, loading, partition inserting and case sealing, the company says. Case print and label integration also are available, it adds.

Also noting the benefits of integrating processes, St. Paul, Minn.-based Delkor Systems Inc. offers its LIF Series Casepacker, which offers speed and efficiency in a compact footprint, the company says. The versatile case packer features a flex loader and flange-seal closer as well as customizable multi-flavor infeed options and infeed reject parameters. The LIF series will load multiple case-pack patterns in a single packaging line, including single or multiple flavors into a variety of retail-ready or distribution-style packages, it adds.

Packing on

Just as the beverage industry will continue to evolve, case packing and wrapping equipment suppliers will do the same. Sustainability will continue to have an effect on both the beverage industry and the industries that support it, experts note.

“As consumers look to reduce their carbon footprint, case packers and wrappers will need to accommodate less corrugated cardboard and fewer plastic materials in an effort to be more eco-conscious,” Schneider’s Jenkins says.

Additionally, Gebo Cermex’s Vasseur notes that further implementation of automation also will continue going forward. “Systems [that are] more and more autonomous, [and] user-friendly to ease the life of operators and maintenance people,” he says.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!