Automation adoption surges with food & beverage manufacturers

Cobots support end-of-line optimization within food & beverage

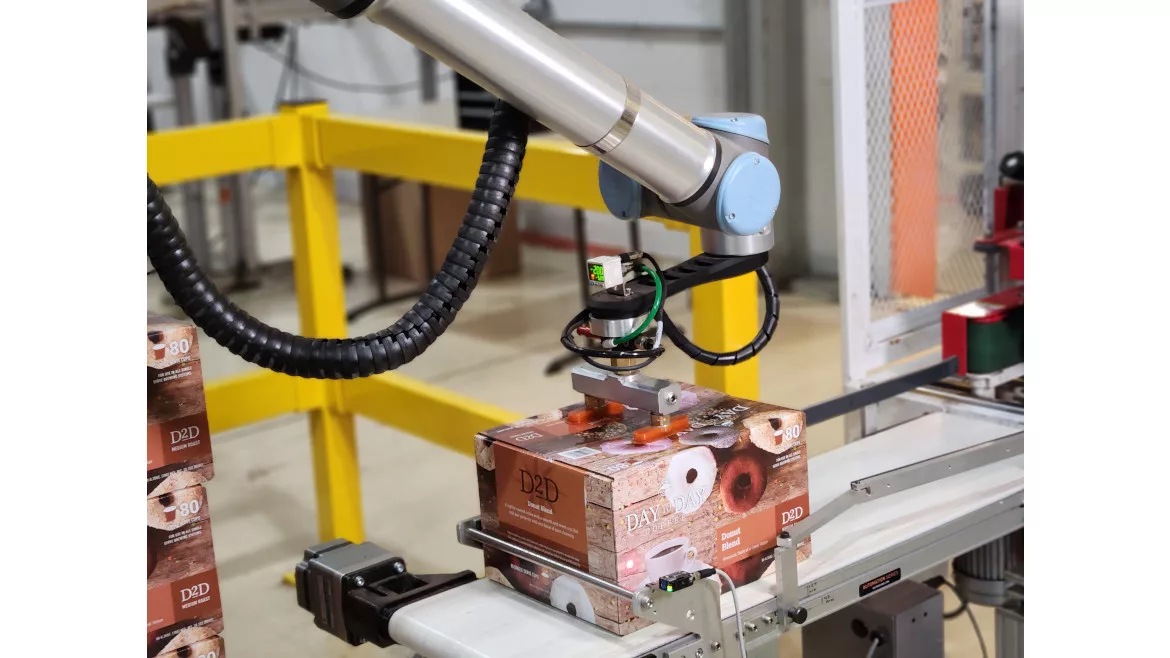

Two palletizers powered by Universal Robots and Robotiq help Chicago-area Napco Brands grow its private-label coffee business despite labor shortages, increasing productivity 15% and reducing injury risk while freeing up eight workers per day for more valuable tasks.

According to the latest International Federation of Robotics (IFR) World Robotics 2025 U.S. companies in the food and beverage (F&B) sector have been feasting on flexible industrial robots, driving the number of installations up by 21% in 2024.

But not all automation is the same, and the F&B sector has unique concerns and requirements, so a little strategic thinking can go a long way to maximizing your automation investment.

Seen from a F&B perspective, the biggest headline grabber from the IFR’s latest World Robotics report is automation adoption increasing year-over-year by a stunning plus-20%.

From pick-and-place, material handling, and palletizing to labeling applications and from food and beverage processing to packaging lines, robots are boosting productivity and profits across the nation’s F&B facilities.

This surge is not just about numbers — it reflects a deeper shift in how packaging and end-of-line processes are being reimagined. Across the sector, manufacturers are seeking ways to keep pace with business demands, and automation is increasingly seen as the answer to packaging at the speed of business.

How cobot-powered automation plays a role

Meanwhile, the ‘Trends’ section of the IFR report notes the important role of cobots in enabling companies to automate such applications via easy-to-use, cost-effective automation with a small footprint that can be deployed next to people. And a case study on cobot-powered automated carton palletizing at a wine maker reinforces the benefits that cobots can bring from improved ergonomics to fast ROI. According to company owner, Volker Raumland, cobots “will unlock new opportunities for the wine industry.”

In truth, there are good reasons to deploy cobots in any sector, but why have collaborative robots found such synchronicity with the requirements of the F&B industry?

For many, the answer lies in the ability to optimize everything at the end of the line. Intelligent automation solutions are now capable of maximizing uptime and productivity, often increasing output by up to 40%. These systems are designed to thrive in dynamic environments, handling frequent changeovers and high-mix product runs with ease —qualities that are essential for F&B producers facing seasonal demand and shifting consumer preferences.

Dynamic environments for every season

Companies in the F&B sector know all about dynamic manufacturing environments with high growth and high variability. Unlike more standardized industries such as automotive or electronics, F&B producers must constantly adapt to changing consumer tastes, seasonal demands, volatile raw-material costs, and shifting regulatory requirements around safety and hygiene.

This churn results in product runs that are often shorter with frequent changes. And this high mix environment requires automation with flexibility to match. It also means that F&B companies are looking for automation that can be both deployed and redeployed quickly by non-experts with minimal downtime between changes. Traditional automation remains a powerhouse for static, highly repetitive tasks, but cannot compete with cobots when it comes to rapid deployment, changeovers and flexibility.

Moreover, in most F&B facilities, floorspace is at a premium, which means companies are looking for automation with a minimal footprint that can (following a risk assessment) be deployed safely next to humans without any fencing. Due to their small form factor and safety features, cobots can be deployed in areas that traditional automation can’t reach, which creates opportunities for F&B companies to implement automation in ways that aren’t possible with traditional solutions. By enabling flexibility, cobots provide a fast way for F&B companies to boost productivity and quality.

Future proofing operations

Faced with labor shortages as its business grew, coffee bean roasting and packing specialists Napco Brands explored whether automation could assist but found the cost of traditional palletizing equipment prohibitive.

“There’s a large barrier to entry when you’re talking millions of dollars in a single packaging line that may or may not help you,” says Eric Latsch, vice president of pperations.

Napco turned to cobots instead, due to the lower capital investment involved, faster ROI, and general ease of use. The company’s cobot palletizers run two shifts, operating 18 to 20 hours a day. Each palletizing cell fills 1,500 boxes, totaling 180,000 single-serve coffee cups packed daily between the two cells. Productivity has increased by about 15%. The company avoided the risk associated with traditional automation investments. ROI was achieved in under a year. Injury risk has fallen. And for eight shifts a day, humans were freed to focus on more valuable tasks.

Because Napco’s costs are now fixed rather than variable, and the system has significantly reduced overtime, the company is able to be more aggressive on bidding new business.

“Having this automation with a higher efficiency has made it possible for us to acquire new customers. We have several new private-label customers that we couldn’t have dreamed of two years ago,” Latsch explains.

While traditional robots can be behemoths with massive reach that are capable of handling massive payloads, cobots are no slouches in either department.

The latest generation of cobots brings more than just efficiency. With advanced motion control, predictive analytics, and future-ready innovation, these systems are built to adapt and scale as business needs evolve. For manufacturers, this means not only faster deployment and supercharged ROI, but also the confidence that their automation investment will remain relevant as the industry continues to change.

Automation hesitation not a factor

Bob’s Red Mill, a whole grain specialist based in Milwaukie, Ore., deployed a cobot palletizing solution with a reach of 68.9 inch (1750 mm) to ensure that the robot could handle the 81-inch pallets used in the facility.

The solution, dubbed ‘miniPAL+’ handles up to 14 cases a minute and the cobot’s 44.1pound (20 kg) payload enables the system to double-pick boxes that each weigh between 4-10 pounds. And automation hesitation wasn’t a factor among workers.

“The employees here at Bob’s were really excited to see this palletizing technology come to their production line; if you are producing well, we all get a share of the company,” explains Nick Chow, engineering and fabrication manager at Bob’s Red Mill. “Automation is key in helping us grow and share our profits, while also reducing injuries so everybody goes home safely.”

As the sector continues to evolve, the ability to deploy intelligent, future-ready automation — solutions that are not only efficient but also flexible and scalable — will be central to maintaining competitiveness. For North America’s food and beverage manufacturers, the message is clear: end-of-line anything, optimize everything.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!