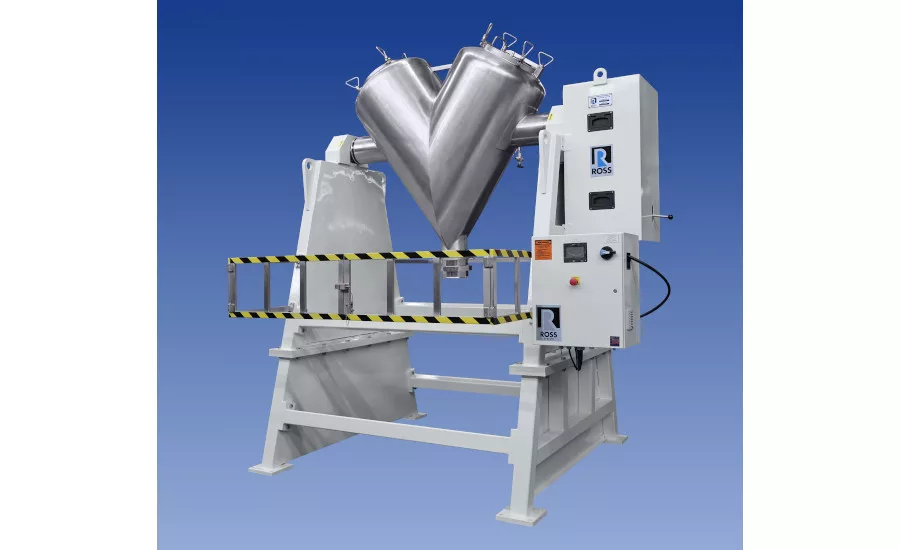

New ROSS blender offers precise mixes of free-flowing solids

The latest blender from ROSS was engineered for applications that require gentle, yet thorough mixing. The ROSS V-Cone Blenders are used across numerous industries where consistency is essential, the company notes. The blenders rotate a V-shaped vessel along its horizontal axis, creating a cascading action that continuously exposes and redistributes materials, it says. The low impact tumbling motion is good for friable ingredients, trace components or materials with significant differences in particle size and density, it adds. The new purpose-built ROSS Model VCB-10 blender was constructed with stainless steel product contact surfaces, featuring a 10 cubic foot working capacity. It supports a maximum bulk density rating of 125-pounds per square foot. ROSS is offering designs for higher densities as well. The vessel rotation is powered by a 7.5 HP TEFC motor, which can achieve speeds up to approximately 20 rpm. A safety rail assembly prevents unintended contact with the blender’s rotating assembly, with a two-section front gate equipped with a limit switch and safety interlock switches and a fixed rear guard rail. A manually operated 8-inch stainless tell type 304 dust-tight butterfly valve provides efficient discharge, with support legs providing a 54-inch clearance beneath the valve to the floor. The NEMA 12 Control Panel includes a 4-inch color touch screen interface for viewing and controlling blender operations, a cycle timer, jog function and an emergency stop pushbutton, the company notes. The control system is pre-mounted and wired to the blender for streamlined installation and startup.

Charles Ross & Son Co. 710 Old Willets Path, Hauppauge, N.Y. 11788; 800/243-ROSS; www.mixers.com

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!