Distribution

Carts, hand trucks indispensable in last mile delivery

Maneuvering loads in tight retail spaces key for carts, hand trucks

Pallet jacks are battery operated equipment that can help operators with delivery, order picking and horizontal transport needs in stores, restaurants and other venues, Chad Kritzman says.

Image courtesy of The Raymond Corp.

The idiom “Don’t put the cart before the horse” illustrates the importance of approaching events or life in the correct order — e.g., before someone has the money in hand, avoid making plans on how to spend it. In beverage distribution operations, hand trucks and carts are indispensable pieces of material handling equipment that help transport heavy, bulky beverage cases from delivery trucks to point-of-sale at retail stores.

Quite simply, hand-operated hand trucks and carts facilitate moving products from point A to point B, making direct-store-delivery (DSD) tasks easier and more productive, and most importantly, safer. The rise in eCommerce also has necessitated the need for effective, efficient equipment to maneuver heavy loads while ergonomically protecting employee’s backs, knees and shoulders from heavy lifting.

MarketWatch suggests that hand truck market sales are projected to increase with a “significant growth rate” during the forecast period of 2021-2027. Manually powered vehicles, which include hand trucks and carts, are most commonly utilized in the manufacturing and production utilities with the retail and logistics segment to be the No. 1 segment, it states.

Image courtesy of Toyota Material Handling

“They provide much-needed maneuverability in tight spaces, such as the back of trailers in transport and store stockrooms to load and unload product,” says Chad Kritzman, product manager for pallet trucks at the Raymond Corp., Greene, N.Y. “Ride-on pallet jacks are also a cost-effective option in long, horizontal travel situations, such as put-aways.”

The material handling industry is evolving to meet transportation, safety and battery requirements, experts note.

“Immense change in the transportation and logistics industries considering independent movement, lifting, and placement of discrete loads in a specific facility has pushed the hand truck market positively,” MarketWatch states. “… As a result of the pandemic, the hand trucks market also experienced a slowdown. Statista estimates that the hand trucks market total worldwide revenue stood at approximately $3.94 trillion in 2019. In 2014, the hand trucks market generated revenues of $5.4 trillion at a record high.”

In 2021, the growth of Class 3 hand-operated and powered-pallet jacks had a significant year-over-year growth of around 40%, says Jena-Christine Lawrence, product planning manager at Toyota Material Handling (TMH), Columbus, Ind.

“As a result of the rapidly evolving supply chain due largely in part by the rising eCommerce demands, customers are driving the demand for pallet trucks to increase their efficiencies in their operations,” Lawrence says.

Raymond Corp.’s Kritzman notes that companies trying to keep up with the eCommerce boom need to make sure that their equipment has the power to last through their shift. “We are seeing many customers switch to onboard and long-lasting energy solutions, such as lithium-ion power to help keep operations running with less downtime,” he says.

In addition to less downtime, NexSys PURE battery is 24% more energy efficient for each charge than flooded lead acid batteries. The Reading, Pa.-based company’s Thin Plate Pure Lead batteries also can help companies cut carbon dioxide and eliminate the use of 13 gallons of distilled water each week, it said in a statement.

As far as how carts and hand trucks are being designed, The Raymond Corp.’s Kritzman notes that more ergonomic features and operator assist technologies are moving carts and hand trucks to the next level.

“One of the first trends being seen is that pallet jacks are now being designed with the operator in mind showcasing innovative tools and ergonomic features that support proper operation,” Kritzman explains. “Another trend that is being seen across the industry is the integration of technology, such as operator assist technologies, into the pallet truck itself. These new technologies help to support efficient operation and reinforce operator best practices.”

“More and more carts and hand trucks are being replaced with electric pallet jacks load backrests and belts to secure the loads. Ergonomically, electric units and the ability to adjust heights is helping workers restrict back problems.”

- Bill Byrd, senior sales manager at Toyota Material Handling

Pivotal to company success

TMH’s Senior Sales Manager Bill Byrd explains that the design of carts and hand trucks is changing, but the main benefit has not: “to make deliveries across uneven parking lots and fit through tight doorways,” he says. “Pepsi developed a ‘GEO’ pallet truck system for store deliveries to use a highly modified 8HBW23 to deliver to stores.”

Additionally, carts and hand trucks are invaluable with last mile delivery, and more companies are adopting electric hand carts to improve ergonomics for delivery drivers who are seeing an increase in SKUs, Byrd says.

Raymond’s new 8910 enclosed end rider pallet truck is engineered with the operator in mind, Kritzman says. For example, the operator compartment has been redesigned to offer additional space and wraparound padded lean points and vibration-absorbing floor pads to maximize operator comfort and reduce fatigue during a busy day.

The company also offers a few styles of walk-behind electric pallet jacks in its portfolio. This includes the Raymond 8210 walkie pallet jack with AC power and the Raymond 8250 walkie pallet jack powered by lithium-ion.

“Both the Models 8210 and 8250 are highly maneuverable and offer the energy efficiency to get the job done,” Kritzman notes. “These are very durable in a variety of applications, which means more uptime and productivity.”

Image courtesy of Toyota Material Handling

TMH’s Lawrence agrees that pallet jacks offer the versatility, flexibility and productivity efficiencies that many customers are looking for in their beverage operations.

“With different capacities, power types, fork lengths and sizes available, they can become an integral part of a total solution offering,” she says.

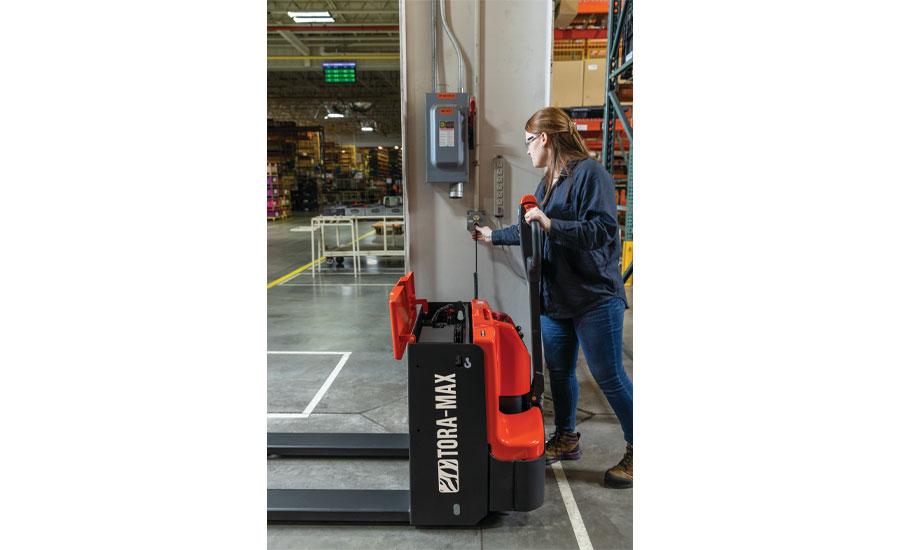

Depending on customer needs, TMH offers a robust range of hand pallet and powered pallet jacks, including 22 new models that launched this year. These include the end rider pallet jack (ER1-ES60.80), low level order picker (CR1-LP60.80), and two new Tora-Max electric walkie pallet jack models (2TWB40 and 2TWB33).

An ideal choice for entry-level pallet truck applications, the Tora-Max Electric Walkie Pallet Jack (2TWB40) includes two 12V maintenance-free lead-acid batteries, an onboard charger, and is designed to efficiently handle as much as 4,000 pounds, the company says. Meanwhile, the new Tora-Max Compact Electric Walkie Pallet Jack (2TWB33) is a great choice for customers looking to replace manual pallet trucks in applications with loads as much as 3,300 pounds, it adds. The new Toyota Enclosed End Rider (ER1-ES60.80) and Low Level Order Picker (CR1-LP60.80) can both handle 6,000-8,000 pounds, in single, double and even triple length forks.

“The ERI-ES60.80 and CR1-LP60.80 are ideal solutions for customers looking to maximize pallet transport or customers creating mixed pallets from lower racking locations,” Lawrence explains.

Moving on up

Experts note that in today’s automation-fueled world and the customization and advanced manufacturing capabilities that accompanies it, hand or electric-powered hand trucks are adapting to provide the delivery and merchandise that employees need to do their jobs efficiently, effectively and safely.

Additionally, when operations shift to implementing new technologies to help move product without the need of labor, Raymond Corp.’s Kritzman predicts that beverage operations will see an increase of warehouses, distribution centers and stores adapt to automated storage systems.

TMH’s Byrd notes: “More and more carts and hand trucks are being replaced with electric pallet jacks load backrests and belts to secure the loads. Ergonomically, electric units and the ability to adjust heights is helping workers restrict back problems.”

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!