Operations

OEMs prioritize sanitation, efficiency for conveyor solutions

Web tools support customization of conveying operations

“Clean up, clean up, Everybody clean up, Let’s work together, Everyone do their share,” is what Dora sings in the “Cleanup Song” from the animated Nickelodeon TV show “Dora The Explorer.” For beverage operations, a growing importance has been placed on using equipment that supports sanitary practices without impeding productivity.

For manufacturers of conveyor systems and supporting materials, sanitation measures have been driving the innovations emerging from this market.

“[W]e are seeing more requests for sanitary rated drive systems for conveyors,” says Chris Wood, industry account specialist at SEW Eurodrive, Lyman, S.C. “End users are looking for easier to clean, non-corrosive units with higher IP wash down ratings to meet FSMA ‘Sanitation Zones.’”

One of the ways that suppliers are supporting more hygienic operations is with the application of drum motors.

(Image courtesy of SEW Eurodrive)

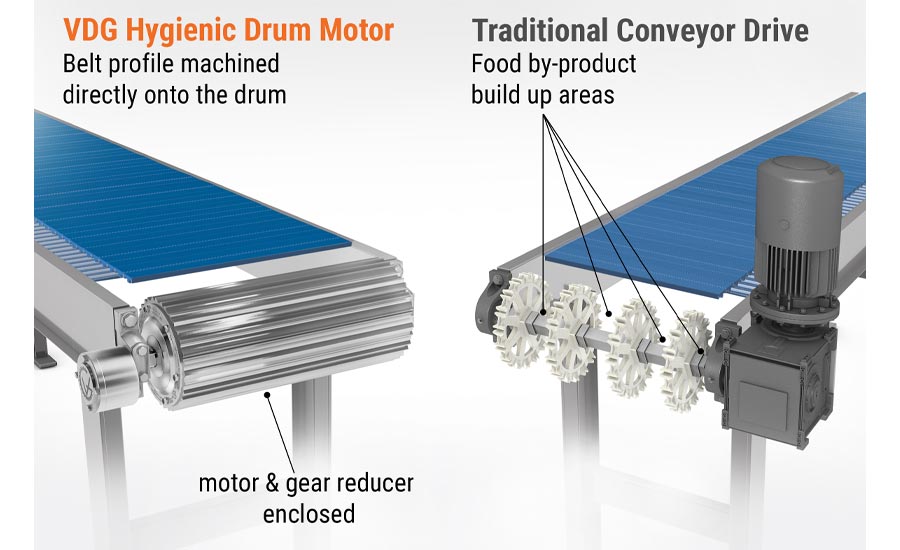

Van der Graaf (VDG), Shelby Township, Mich., has been manufacturing drum motors for the past 35 years to provide reliable solutions to the material handling industry. Noting that VDG’s drum motors are among the most sanitary drives in the market, Alex Kanaris, president of VDG, explains that because the motor, gear reducer and moving parts are all enclosed within the drum, sprockets are not required since the belt profile is machined directly onto the 316-stainless steel drum to drive modular style conveyor belts, and reduces wash down time.

Because the COVID-19 pandemic has heightened sanitation practices, these design systems are becoming more essential.

“VDG always had a strong focus on hygiene, however, the COVID-19 pandemic has heightened the importance to further elevate the hygiene level of our product and therefore decided to eliminate the manufacture of older designs that use sprockets to drive modular style conveyor belts,” Kanaris says.

Driving efficiency

Although sanitation has received increased attention as of late, experts know that supporting efficient operations remains a driving force within conveyor systems.

SEW Eurodrive’s Wood explains that the company offers efficient, complete drive systems that feature decentralized controls, which use two-thirds less energy and half the installation time.

“This in conjunction with the highest efficient IE-5 Movigear Permanent Magnet drive system will boost overall efficiency of the bottling line,” he says. “The Movigear has higher starting torques, uses smaller motors and offers wider speed ranges reducing drive variants and the spares that are needed in the store room.”

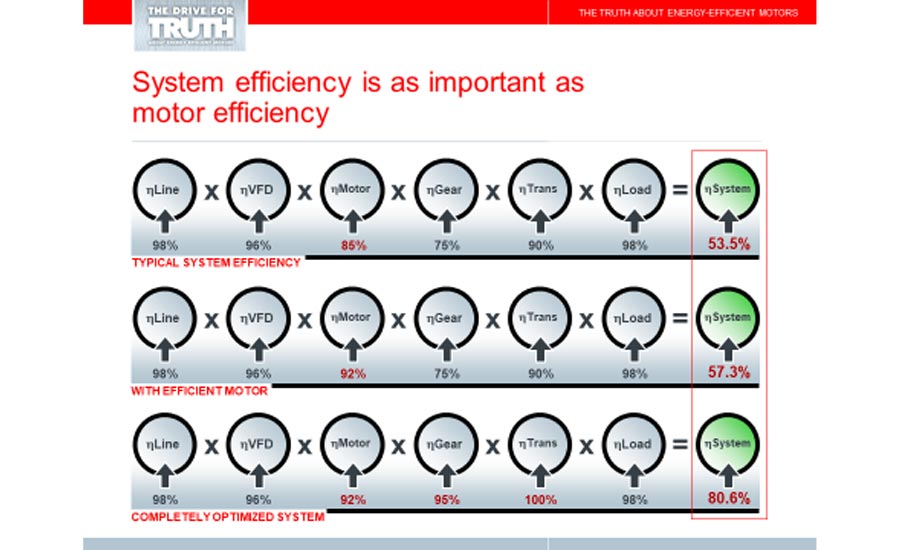

When working with partners, Wood highlights that the company advises operators to consider total drive efficiency when updating conveyor solutions.

“By changing the conveyor drive design to a more efficient motor, gear reducer and eliminating inefficient external drive components like roller chains and belts, efficiency can be boosted to over 40 percent or more,” he says.

(Image courtesy of VDG)

VDG’s Kanaris also highlights how drum motors support efficient operations. In addition to space savings, Kanaris notes that efficiency is among the key benefits that can be realized by VDG customers.

“It uses approximately 25 to 30 percent of the energy that the traditional conveyor drive is using,” he explains. “It’s much safer because you have no external rotating components outside the conveyor frame that can be hazardous to workforce safety.”

The drum motor has a 96 percent mechanical efficiency and does not require any scheduled maintenance. Kanaris explains that VDG drum motors are designed for 80,000 hours of continuous operation, reducing total cost of ownership.

But like many industries, original equipment manufacturers recognize that customers’ adoption of technology and customized needs are evolving. To support this trend, Hartland, Wis.-based Dorner announced earlier this year that Helix CAD models are now available for download in Dorner’s D-Tools, Dorner’s online conveyor configurator. Using D-Tools, project managers now can design a FlexMove Helix conveyor to fit their exact application within minutes.

Dorner’s D-Tools provides instant validation of fit with complete 3-D CAD assembly models, the company says. Operators can create simple or complex Helix Conveyor packages, as well as individual components such as gearmotors and mounting packages, support stands and accessories, it adds.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!