Supplier's Marketplace

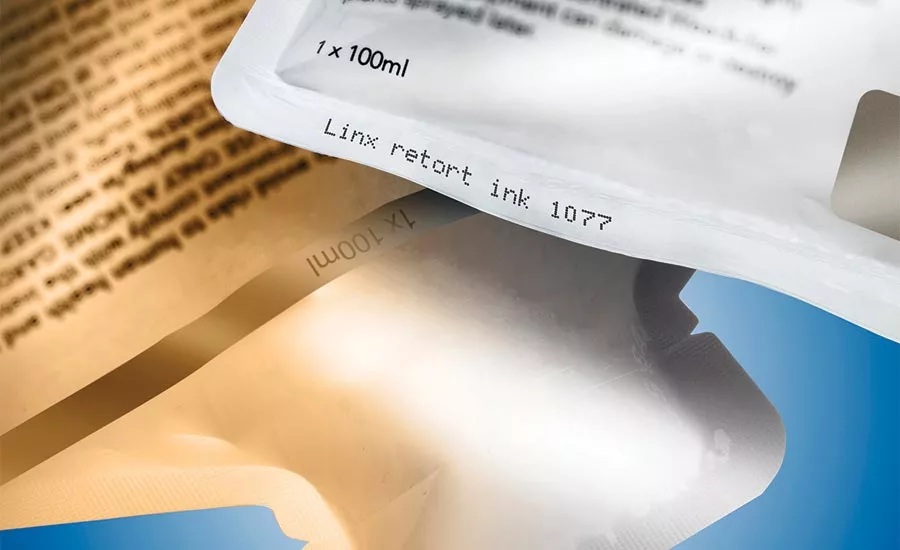

Linx Printing adds new retort ink to foster consistent coding of pouches, cans

Dye-based ink works in wet retort and high-temperature conditions

Linx Printing Technologies Inc. announced it has added a new ink to its Linx range to meet increasing customer demands for retort applications. The ink has been specially formulated to resist moisture, color change and transference, is designed to foster consistent coding through pouch, and can retort applications where the contents are cooked in the packaging after they are coded, the company says. Developed for the company’s Linx 8900 and 8800 Series of continuous ink jet (CIJ) coders, the Linx Black retort ink 1077 is a dye-based MEK ink specifically designed for use in typical sterilization and wet retort process conditions. The ink’s special formulation enables the printers to code through a thin layer of oily film or grease, while its components enhance its adhesion under moist and high-temperature conditions. The ink also delivers consistent adhesion and transfer resistance, as well as excellent durability and legibility on a range of materials after processing, it says. Ideal for products that are coded before cooking, the ink is suitable for use on many materials including metal cans, formed aluminum and plastic packaging such as polyester (PET) pouches.

Linx Printing Technologies Inc., 8 Stocks Bridge Way, St Ives, Cambridgeshire, PE27 5JL, United Kingdom; +011/44-0-1480-302-100; linxglobal.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!