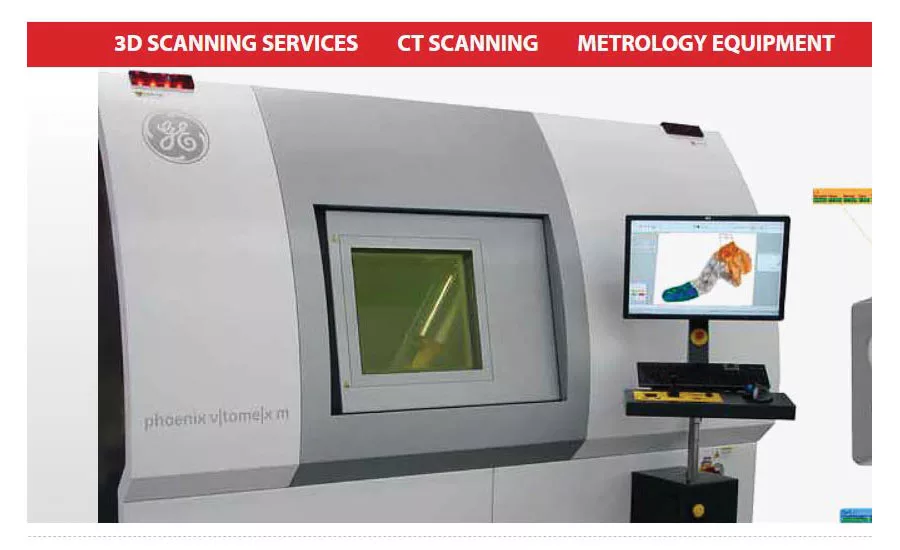

Exact Metrology expands 3-D scanning operations

CT scanner checks seals on bottles, cans

Exact Metrology expanded the company’s capability in 3-D scanning to microns by adopting the new Metrology Grade GE Phoenix v|tome|x m, a CT scanner system with dual tube technology, nanofocus to 180Kv and microfocus to 300Kv. The new equipment will enable measurement to 2 microns, even on denser parts. The new system, which includes full CT automation, click-and-measure capability and dual tube technology, can perform analyses on an extremely wide range of samples, from high-resolution nano CT of low-absorbing samples to the high-power micro CT applications such as engine turbine blades. Within the beverage industry, bottlers and canners are able to use the unit to check the tightness of seals, the company says. Other applications for the device include light metal castings, electronic assemblies, thermoplastic molded and composite parts, plus all types of machined metals. The Phoenix system features a temperature stabilized detector array — as many as 30 fps — for fast CT data acquisition on workpieces as wide as 500 mm diameter and 600 mm in height, weighing as much as 110 pounds, it says. Compared with conventional tactile or optical CMMs, this new scanner system can generate a first article inspection report including internal dimensions in less than one hour, with high accuracy and repeatability, the company says.

Exact Metrology Inc.

11575 Goldcoast Drive

Cincinnati, Ohio 45249

866/722-2600

exactmetrology.com

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!