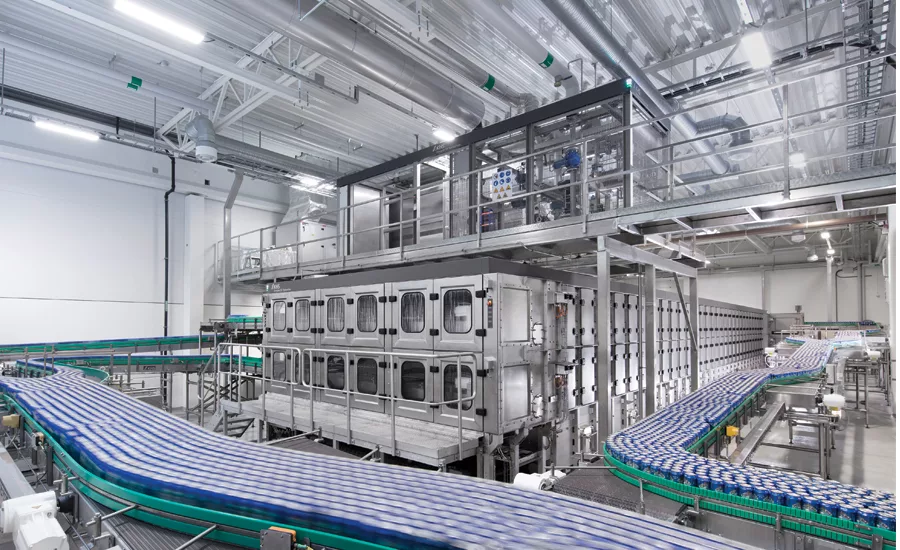

KHS releases new tunnel pasteurizer

Innopax SX maintains consistent temperature regardless of conveyor speed

KHS USA announced the release of Innopas SX, which is designed to give bottlers greater flexibility in the pasteurization process. The tunnel pasteurizer offers a high degree of microbiological safety, new functions that can be quickly and easily retrofitted, and a modular design with optimized spare part management, according to the company. The Innopas SX facilitates the necessary pasteurization of filled and sealed beverage containers in cans, glass and PET bottles and products that require longer shelf lives, the company says. The pasteurization unit (PU) also reacts variably to changes in conditions. For example, if a fault occurs during the pasteurization process, the process temperatures are kept under control in the hot zones of the tunnel pasteurizer to ensure product safety and flavor stability, it adds. The new pasteurizer also features flexibility and yield savings in energy and media; a speed regulation function; and individual zone temperatures that are automatically raised or lowered depending on the conveyor speed. In addition, the pasteurizer can adjust to match the line behavior within a range of 50 to more than 100 percent of the nominal capacity for most processes without making any drastic changes to the pasteurization units and maximum product temperature, it adds. The tunnel pasteurizer is designed for easy operation with optimal access to the maintenance and cleaning system.

KHS USA

880 Bahcall Court

Waukesha, Wis. 53186

262/797-7200

khs.com

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!