Beverage equipment suppliers' new products aid operations

New innovations in conveyor systems, reusable pallets

Sustainable stacking

Orbis Corp. introduced its new StakCap, a top cap and pallet system for the packaged goods and food processing industries, the company says. The new system will secure 40- by-48-inch pallet loads for easier and more efficient material handling while enhancing the safety and maneuverability of double-stacked pallets, it adds. Additionally, its low-profile design allows for a high nesting ratio, creating more floor space in the plant, storage areas and trailers. Designed to create more secure loads with an interlocking top cap, StakCap also can be recovered, recycled and reprocessed at the end of its service life, it adds.

Orbis Corp., 1055 Corporate Center Drive, Oconomowoc, Wis. 53066; 262/560-5000; orbiscorporation.com.

Greasing the bearings

Klüber Lubrication NA LP offers Klübertherm HB 88-182, a versatile, long-term grease that provides enhanced protection against friction and wear-on rolling bearings operating at high thermal loads, medium speeds and at temperatures as hot as 180 degrees Celsius, the company says. Based on a thermally stable base oil, polytetrafluoroethylene thickener and special additives, the synthetic HB 88-182 closes the performance gap between greases based on perfluorinated polyether oils and conventional high-temperature greases when exposed to high thermal loads, it adds. The Klübertherm HB 88-182 features enhanced degradability at high temperatures and can be used for rolling bearing applications in corrugating machines, rotary unions, generator bearings, conveyors, hydraulic couplings, smoke extractor motors and ceramic ovens, it adds.

Klüber Lubrication NA LP, 32 Industrial Drive, Londonderry, N.H. 03053; 603/647-4101; klueber.com.

Can innovation

Crown Holdings Inc. partnered with La Colombe Torrefaction to create a textured draft latte in a can, which is currently being sold in La Colombe cafes and online, using Crown’s new, proprietary InnoValve can. The InnoValve can is a 10-ounce sleek-styled pressurized beverage can that is specifically designed for textured drinks, the companies say. It features a one-way valve that is inserted into the bottom of the container and allows nitrous oxide gas to be infused into the coffee beverage resulting in café-style foam. The can also features an attached lip guard that is designed to imitate the feel of a to-go coffee container, it adds.

Crown Holdings Inc., One Crown Way, Philadelphia, Pa. 19154; 215/698-5100; crowncork.com.

Increasing line efficiency

Butler Automatic Inc. introduced its SP3HSL series automatic film splicer, which can improve line efficiency in consumer packaged goods and shrink-sleeve packaging operations, the company says. The automatic web splicing system eliminates downtime caused by film-roll changing and increases line efficiency in sleeved packaging operations by 9 percent, generating a return on investment of fewer than three months, it says. Running at speeds as fast as 450 feet a minute, the SP3HSL automatically splices the end of each expiring roll of film onto the new roll, which increases production time. It can work on new production lines and also can be retro-fitted for existing packaging lines, it adds.

Butler Automatic Inc., 41 Leona Drive, Middleborough, Mass. 02346; 508/923-0544; butlerautomatic.com.

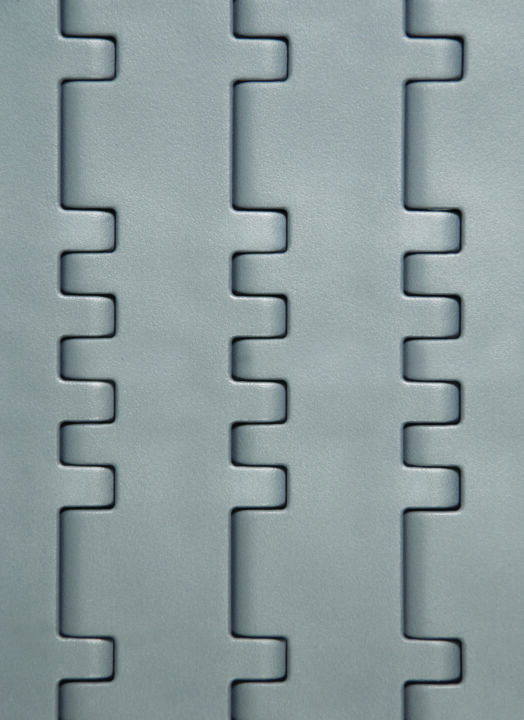

Safety in container conveying

Rexnord announced the launch of a new flame-retardant, low-friction (FRPLUS) material for the aluminum and steel can manufacturing industry. Designed for container conveying applications, the FRPLUS requires little or no external lubrication to maintain low friction between the containers and chain, the company says. Other features include stability in container flow and behavior during conveying, the ability to withstand chemicals and drawing fluids used in can manufacturing, and minimal dusting. Additionally, the company’s proven chain-sprocket interaction requires no take-ups while using a catenary sag to absorb chain wear and elongation, it adds. The Rexnord FRPLUS can be used with the Rexnord MatTop Chain 500, 1000, 1500, 5930, 7700 and 8500 series.

Rexnord, 4701 W. Greenfield Ave., Milwaukee, Wis. 53214; 414/643-2366; rexnord.com.

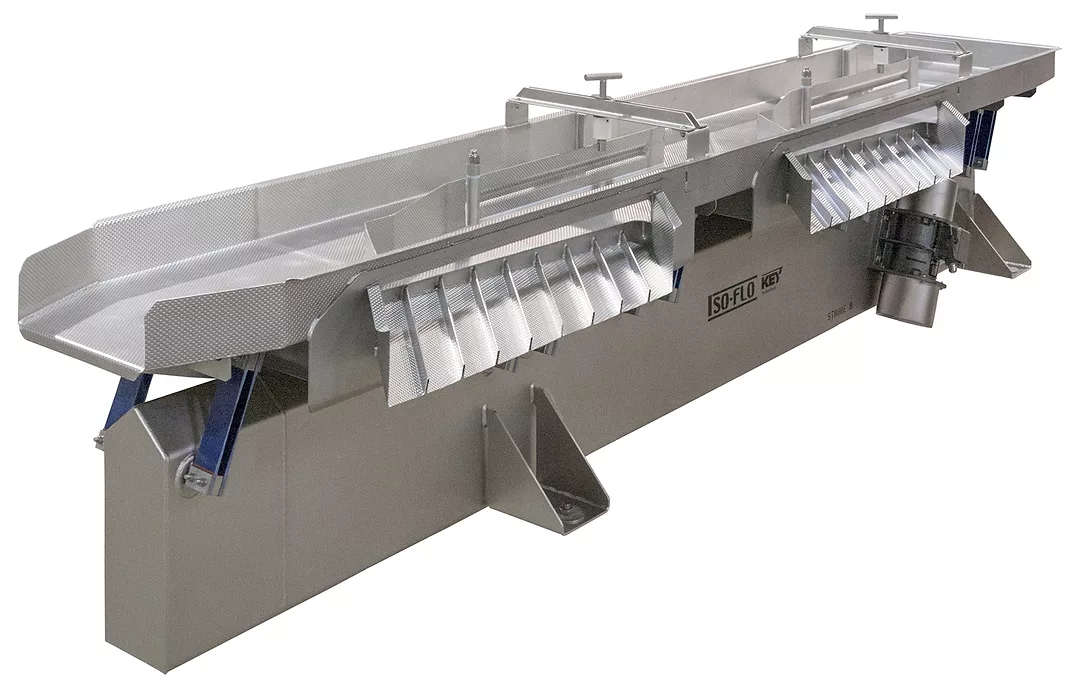

Re-engineered conveyor construction

Key Technology Inc. introduced its re-engineered Iso-Flo vibratory conveyors with mono-beam construction, which features an innovative single-structure frame that can be completely tucked under the conveyor bed, the company says. Ideal for a wide range of food processing and packaging applications, the conveyor’s mono-beam architecture has a sleek design that can be used on distribution shakers with side discharges as well as transfer shakers, collection shakers, feed shakers and inspection shakers, it adds. Because the frame and spring arms are located under the conveyor bed rather than on the sides, mono-beam inspection shakers enable operators to get closer to the bed for improved product visibility and ergonomics. The UL-certified Iso-Flo conveyors feature oil-free drives, elastomer isolators, scalloped flat bars, internal ground arms and contain no laminations, which maximize equipment hygiene and help meet rising sanitary standards and regulatory requirements. Additionally, the versatile mono-beam conveyors can be floor-mounted with four legs or two legs on T-bars, or they can be mounted to other machinery or suspended from overhead, it adds.

Key Technology Inc., 150 Avery St., Walla Walla, Wash. 99362; 509/529-2161; key.net.

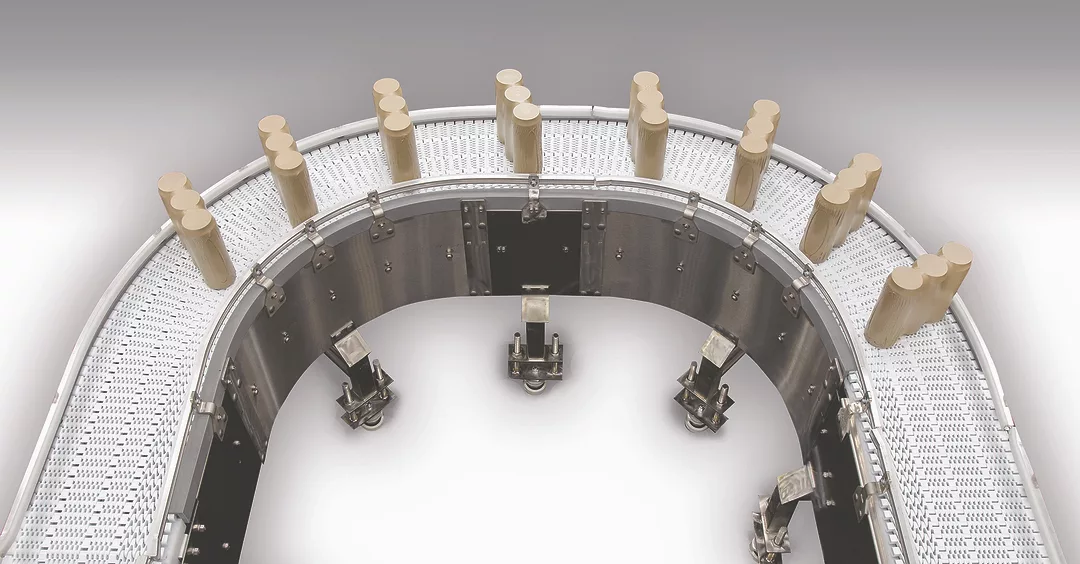

Turn-key solution

To keep pace with smaller packaging sizes and smaller plant footprints, Intralox LLC announced the release of its Series 2300 flush grid nose-roller tight turning belt, which is designed to achieve optimal function between belt speed, load distribution, and turn and width severity, the company says. The patent-pending design allows the belt to run around a 0.75-inch (19.1 millimeters) diameter dynamic nose-roller while executing side flexing turns as wide as 180 degrees without edge bearing, it adds. Other features include improved load-sharing and a robust design; enhanced belt life and minimized unscheduled downtime; layout flexibility with a turn ratio of 1.7 times belt width; and a maximum belt opening of 0.24 inches (6.2 millimeters) for increased safety in high-load, high-cycle applications, it adds.

Intralox LLC, 301 Plantation Road, Harahan, La. 70123; 800/535-8848; intralox.com.

Consistent temperature control

RAE Coils, a division of RAE Corp., announced the launch of new insulated coil boxes, which are designed for applications in which maintaining different room temperatures is necessary, the company says. Unlike traditional HVAC systems, where temperature is controlled on an equipment level, RAE’s coil boxes control temperatures on a by-room basis or by floor in heating, cooling or dehumidification systems, it adds. Available in galvanized or stainless steel, the coil boxes feature a double-wall construction with two-inch fiberglass insulation. Its 18-gauge stainless steel interior construction is ideal for wash-down applications, it adds. The coil boxes can be designed and built to customers’ specifications, it says.

RAE Coils, P.O. Box 1206, Pryor, Okla. 74361; 918/825-7222; rae-corp.com.

Laser sharp focus

NII Laser Technology PJSC introduced its dynamic laser marker (DLM) equipment, specifically developed to provide integrated high-power, additive-free laser marking systems on the inside and outside surfaces of beverage closures, caps and crowns, the company says. Its DLM-BC Pro-D system combines two laser technologies and provides additive-free laser marking on most closures’ colors at maximum speeds with sharp precision and efficiency, it adds. UV and fiber lasers are virtually free of maintenance and are safe for food and beverage applications, it says.

NII Laser Technology PJSC, 14 Nauki Ave., Kharkiv, Ukraine 61166; 011/380-57-702-12-07; niilt.com.

Gauging guards

Griffco Valve Inc. introduced a new line of gauge guards and instrument isolators to enhance the performance of chemical feed systems. The Griffco Gauge Guard helps ensure that optimal pressures are maintained and diaphragm isolators protect instruments against chemical attack, the company says. Additionally, the gauge guards and isolators will perform in any position and feature a calibration screw for zeroing, it adds. The guards and isolators have a maximum operating pressure of 250 pounds per square-inch (psi) at 70 degrees Fahrenheit, with a standard pressure range of 0 to 160 psi with pressure gauge options of 60, 100 and 200 psi. The unit is available with or without the gauge in economy, mid-range and premium gauge options, and 3-D CAD drawings in several formats also can be downloaded from the company’s website, it adds.

Griffco Valve Inc., 6010 N. Bailey Ave., Suite 1B, Amherst, N.Y. 14226; 800/474-3326; griffcovalve.com.

Centrifugal force

Kurt Manufacturing Co. introduced the Kurt Top-Load Gage System that measures in real time the downward axial forces exerted on a container during sealing operations and transit, the company says. After measuring the forces at the source, data is wirelessly transmitted via Bluetooth or can be downloaded by wired connection, it adds. Beverage line operators can adjust sealing pressures while filling or correct shipping and handling to ensure containers withstand axial forces. Additionally, the gage can record downward forces to cans or bottles weighing between 500 and 1,000 pounds at data-collection speeds of as high as 500 readings a second with a peak capacity of 20,000 samples, it adds. The user-configurable system is available for 12- and 16-ounce cans, 12-ounce slim cans, 330-ml European cans, and aluminum-threaded bottles and glass bottles; other specific sizes also can be accommodated, it adds.

Kurt Manufacturing Co., 9445 E. River Road NW, Minneapolis, Minn. 55433; 877/226-7823; kurtworkholding.com.

A water-softening solution

Watts Water Technologies offers its OneFlow anti-scale system for commercial applications. Available in cartridge and tank-style units for both hot and cold water lines, the systems are designed with inlet sizes from one-half inch to two inches (15-50 mm) and flow rates between 0.5 and 450 gallons a minute for each housing or tank, the company says. Additionally, the system prevents scale buildup and requires minimal maintenance while using no salt, regeneration or electricity. OneFlow treatment technology uses template-assisted crystallization to break away calcium and magnesium minerals in the water, enabling the inert microscopic crystals to harmlessly move through the plumbing while preventing hard scale buildup inside pipes or appliances, it adds.

Watts Water Technologies, 13700 Highway 90 West, San Antonio, Texas 78245; 800/659-8400; watts.com.

Elbowing in

Paul Leibinger Inc. announced the release of the Elbow, an printhead for JET3up and JET3up PRO inkjet coding machines, the company says. At just 19 centimeters (7.48 inches), the Elbow can be installed on virtually any production line, even those with very limited space, it adds. Made in Germany, Leibinger printhead coding machines enable manufacturers to mark, number and code products from above when space is lacking for standard printheads because the transition to the umbilical is made at a 90 degree angle, it adds. Other features include an automated Sealtronic nozzle seal, which prevents ink from drying out even during long shut-down periods because the gutter and the nozzle form an airtight circuit — just like a sealed paint can —keeping the ink fluid and the inkjet printer always ready to go, according to the company.

Paul Leibinger Inc., 2702 #B Buell Drive, East Troy, Wis. 53120; 262/642-4030;leibinger-group.com/en.

Product purity

ULVAC Technologies Inc. offers vacuum distillation systems, such as the Centrifugal Vacuum Distillation CEH-400B II, which is designed for highly functional, efficient small-lot manufacturing and features quick changeover to handle a variety of raw materials, the company says. Ideal for liquid-separation applications in the healthcare, electronics and food industries, the system provides product purity and removes unwanted materials by using heat to vaporize and separate compounds within a liquid, it adds.

ULVAC Technologies Inc., 401 Griffin Brook Drive, Methuen, Mass. 01844; 978/686-7550; ulvac.com.

Lighting it up wirelessly

Legrand North America offers a new two-button, programmable keypad that provides wireless, full-scene lighting control, the company says. The Vantage RadioLink EasyTouch II keypad provides seamless scalability, is designed for quick installation without the need to run new wires and is ideal for retrofit projects, replacing standard 3- or 4-way switches, it adds. The keypad also fits the needs of any new construction projects and features a robust communication protocol, incremental system expansion, and fully synchronized on/off and ramp up/down of lighting loads. Other features include an expanded wireless distance for keypad-to-controller communications; multi-event programming; control of discreet loads or scenes on a single button, hidden, ambient light and IR sensors; and custom color options.

Legrand North America, 600 Woodlawn St., West Hartford, Conn. 06110; 877/295-3472; legrand.us.com.

Paper perfection

Zanders GmbH, a manufacturer of specialty papers and boards, relaunched its Silver digital range, which is designed for toner-based digital printing, the company says. The two-sided, double-coated paper and board is available in both gloss and matte finishes, it adds.

Zanders GmbH, 51465 Bergisch Glabbach, Germany; 011/49-02202-15-0; zanders.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!