Filling machines give beverage categories their fill

Filling systems address packaging, category formats

Years ago, the word “flexibility” carried a different meaning in the filling systems space — it might have referred to different packaging formats and beverage

|

categories. Today, proliferation of SKUs and the increasing number of particle-filled beverages have stretched the word’s definition in the beverage industry.

“Flexibility nowadays is not only related to the possibility of managing multiple sizes but also to having the widest range of products to fill,” says Federico Zannier, filling lines global sales manager for SIPA SpA, Vittorio Veneto, Italy. For instance, the company’s new generation of EVO valves is capable of working with multiple product types, including pulpy beverages, fruit-filled drinks, carbonated soft drinks, cold-filled juices and more.

Likewise, one of Krones USA’s most recent introductions is its FlexiFruit system, which utilizes two filling carousels — one for pulp and another for juice — to deliver a more homogenous mixture with better mouthfeel for the consumer, explains Barry Fenske, product manager of the filling division for the Franklin, Wis.-based company.

Consumers are increasingly demanding healthier and more natural drinks. As a result, beverages produced with fruit pulp and particles are on the rise, according to Sidel Inc., Norcross, Ga. To meet this rising demand, the company added technologies for hot-fill and aseptic bottling of products with particles or pulp in polyethylene terephthalate (PET) bottles to its portfolio.

In addition to new particle-filled beverage categories, SKU proliferation is causing the number of packaging or product changeovers to increase, says Bob Pease, director of the wet end product group for KHS USA Inc., Waukesha, Wis. As a result, one of the company’s most common requests from its customers is for rapid, toolless changeovers, he says. Therefore, the company has reduced and simplified its container handling components, particularly for PET bottle applications, which in turn reduces container changeover times. In addition, it redesigned internal product-contact channels and surfaces for maximum sanitation, he adds.

“This means that minimum product is lost at changeovers,” Pease explains. “The machines are rinsed and sanitized quickly and thoroughly, saving water and energy. The changeover processes are now augmented by automation, not only contributing to time savings but also ensuring that quality protocol is followed time after time.”

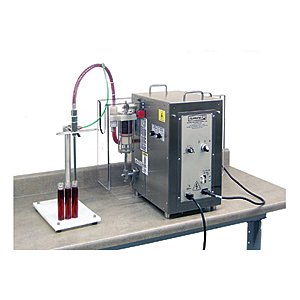

Aaron Saxton, director of sales and marketing for Baltimore-based Filamatic, adds that changeover in less than 30 minutes, unique container handling, multiple metering technologies on a single system, clean-in-place (CIP) systems, disposable product-contact parts, and a combination system of volumetric fills with a product level are requested most among the company’s customers. Featuring a modular design, Filamatic’s DFS filling system allows customers to select their metering technology, and it features a patented trolley system that enables quick changeover, Saxton says.

“Changeover, system flexibility, built-in system intelligence, clean-in-place, validation [and] throughput are all things that our customers challenge us with on a daily basis,” he says.

Universal Packaging reduces changeover time by offering CIP-compatible filling valves and snap-in vent tubes for high-speed rotary machines, says Elihu Rivera, sales engineer for the Orange City, Fla.-based company.

Furthermore, many beverage-makers are looking for high-speed lines that focus on packaging optimization, SIPA’s Zannier says. Sustainability and total cost of ownership are the main drivers for these operators, he adds.

“With the many changes in PET bottles, filling equipment has adapted to keep up with the growing demand of these different packages,” Universal Packaging’s Rivera says. This includes faster, bigger volumetric filling machines, faster filling valves, better depalletizers, faster case packers, faster cappers and more, he says. “Our industry changes constantly, and in order for us to compete, we have to change with the times.”

Krones USA’s Fenske notes that operators want to run lighter-weight PET bottles and caps, and they want their filling systems to be better for the environment. Krones USA has lightweighted its change parts and includes locking systems on its filling systems that require fewer hands to change the parts out, he adds.

KHS’s EVO Glass Filling Platform features a design for beer and wine, offering eco-friendly operation, flexibility and hygienic features, Pease says.

The introduction of multiple can sizes — as well as glass and PET bottles — have made a significant impact on filling systems, according to experts. Can filling operators need the flexibility to run lids of various diameters as well as cans of different heights, explains Ed Ruble, engineering manager for Adcor Packaging Group LLC, Baltimore.

“We have adapted can fillers to accept these multiple can sizes, adding improved elevating systems to change can heights as well as developing quick change-handling parts to help facilitate faster and more efficient changeovers from can size to can size,” he says.

To accommodate the diversity of packaging options in the market, Adcor’s customers are upgrading older equipment to newer technologies and designs, such as electronic level, pressure control and temperature systems, Ruble says.

Equipment manufacturers also are transitioning to modular-designed systems that can be combined from the start or retrofitted with cappers, blowing machines or labeling machines, according to a drinktec 2013 press release.

For instance, KHS introduced the Innoblow-Fill Bloc, which combines the self-manufacture of bottles in-line with filling operations, Pease says. Additionally, SIPA recently launched its Blendfill solution, which features complete integration between the mixer and the filler, minimizing changeovers, CIP systems and total cost of ownership, Zannier says.

Equipment that merges blow molding and filling is standard in the beverage industry, and solutions that combine blow molding, labeling and filling also are popular, he says. “If you consider that only a few years ago air conveyor-based solutions were the only alternative, what can we expect for the future?”

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!