Recyclability, convenience among reasons beverage brands opt for aluminum packaging

Product protection and size variation add to aluminum’s appeal

Image courtesy of Mananalu

In the Nickelodeon series “The Fairly OddParents,” fairies Cosmo and Wanda are assigned to 10-year-old Timmy Turner. As Timmy’s fairy godparents, Cosmo and Wanda are required to grant Timmy’s wishes, no matter how demanding or out-there the wishes might seem.

Although no fairies are involved in the growing demand for aluminum beverage packaging, the primary packaging seems to be on every beverage-makers’ wish list.

Ron Skotleski, vice president of sales and marketing for the North America beverage division at Crown Holdings, Tampa, FL, describes demand for aluminum beverage packaging as strong and steadily increasing.

“As consumers continue to reach for convenient and sustainable packaging formats, brands are leaning into expanding and launching beverages via aluminum cans,” he says. “Currently in North America, over 80% of new products introduced in the market are launched in cans first.”

Skotleski notes that there is a beverage for every aspect of life, from water and nutritional drinks to cocktails. He suggests that the landscape for beverages, especially those in aluminum cans, will only continue to expand.

“New beverages are being launched left and right based on consumer preferences — ready-to-drink (RTD) cocktails, energy drinks, sparkling water and better-for-you sodas are top of mind for consumers and areas where we are seeing the most action,” Skotleski explains. “Convenience and sustainability are two of the main requests coming from consumers.”

The expert goes on to say that the aluminum can is “ideal” because its lightweight, recyclable and circular format gives consumers the convenience of “on-the-go” while remaining one of the most environmentally friendly beverage packages.

“In addition, the branding opportunities through aluminum cans are endless — sleek, striking colors and designs, tactile finishes and varied portion sizes allow brands to carry through their messaging to provide a premium, more personalized customer experience,” Skotleski says.

Daniel Wachter, CEO of Chromatic Technologies Inc. (CTI), Colorado Springs, CO, also notes that demand for aluminum packaging is steadily increasing.

Wachter points to factors such as environmental concerns, lifestyle preferences, visual marketing strategies, product quality considerations, craft beverage trends and the efficiency of aluminum recycling processes as driving the demand.

“Aluminum is highly recyclable, and existing infrastructure supports efficient collection, processing and reuse, aligning with the broader sustainability goals,” Wachter explains. “The rise in on-the-go consumption contributes to the popularity of convenience packaging like aluminum cans. As new entrants join the beverage industry, aluminum cans are preferred for their premium and distinctive packaging, especially craft beverages, sodas and energy drinks.”

Moreover, aluminum cans are a creative canvas for eye-catching designs, making them visually appealing and conductive to effective branding, Wachter says.

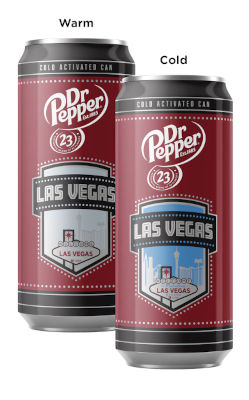

“At CTI, we leverage our expertise in color-change ink technology to enhance brands, creating interactive and distinctive consumer experiences,” he explains. “The surge in craft beverages, encompassing craft beer and specialty soft drinks, has created a niche for unique and visually appealing packaging, further driving the demand for aluminum.”

Further, Wachter notes that aluminum stands out for its exceptional protective properties, guarding against light and air while ensuring the preservation of beverage freshness and quality.

He explains that this attribute is crucial for products like beer and soft drinks, where maintaining the original flavor profile is extremely important.

The sleek and modern aesthetic of aluminum cans also attracts consumers, Wachter says, and contributes significantly to brand recognition — especially in a market full of premium and specialty beverages.

Expanding expectations

As aluminum beverage packaging has moved beyond traditional formats, including cups and bottles, experts highlight how the packaging material is ripe for innovations.

Crown Holdings’ Skotleski says that the market constantly is evolving and that aluminum packaging has plenty of opportunities to address the needs of various beverages — with the potential to expand outside the traditional can format.

“However, while aluminum can be utilized in numerous fashions, we see the beverage can itself remains the most dynamic packaging option across categories and consumption settings,” he explains. “ … The size options and design possibilities with aluminum cans are endless and have increased opportunities for brands that may not have existed previously.”

CTI’s Wachter expresses similar sentiments, noting that the evolution of aluminum beverage packaging has paved the way for new growth and innovation in the market.

“This diversification enables reaching a broader consumer base by tailoring packaging to diverse preferences and needs,” he states. “Additionally, the trend toward premiumization in packaging, particularly for sleek and premium appearances, elevates the perceived value of brands, especially within the premium and specialty beverage sector.”

Wachter says that introducing aluminum cups and wine cans to the market has offered new features, like resealable lids in aluminum bottles and stackable cups for convenience. The outdoor and on-the-go convenience of such products, he adds, makes them ideal for various events, such as concerts, festivals and picnics.

Image courtesy of Chromatic Technologies Inc.

“Furthermore, expanding wine into aluminum packaging creates an excellent opportunity to support a more comprehensive recycling beverage infrastructure,” Wachter notes. “As an innovation partner, CTI helps to promote this growth through our expertise in color-changing inks applied to metal deco. Concept tests and sales results demonstrate high consumer acceptance, brand recognition, preference and improved market performance.”

Although supply chain constraints have influenced the market, Wachter notes that challenges have come in the form of design flexibility and recycling complexities.

“At CTI, we recognize these limitations and work collaboratively with our dedicated suppliers to address these issues proactively,” he explains. “Our suppliers are actively exploring innovative solutions to enhance the versatility and recyclability of aluminum packaging.”

To overcome challenges related to design flexibility, Wachter says CTI employs its expertise in color-changing ink technologies. The company contributes to the expanding possibilities for aluminum packaging by focusing on creative and visually engaging designs.

“Our aim is to demonstrate that aluminum packaging can be sustainable while offering diverse and attractive design options,” he explains.

Crown Holdings’ Skotleski says that, during the height of the COVID-19 pandemic, supply and transportation issues challenged the industry, but the challenges have since been addressed.

“The surge in demand during this time and beyond certainly created the need for greater industry capacity — Crown has answered that call with three new facilities in the last few years that are serving brands and helping them meet increased demand from consumers,” Skotleski explains.

Making it in the market

As for which beverage categories are turning to aluminum packaging, CTI’s Wachter says there has been an uptick in different categories embracing aluminum.

“Some of the most noticeable increases in aluminum packaging usage have been observed in categories like craft beers, hard seltzers, ready-to-drink beverages such as cocktails, teas, regular coffee and cold brew coffee, energy and sports/functional drinks, wine and even sparkling water,” he states. “The effective barrier properties of aluminum cans further contribute to preserving the flavor and quality of these diverse beverages.”

Crown Holdings’ Skotleski suggests that brands are adopting aluminum cans at higher rates than any other substrate across all beverage categories. He notes seeing a spike in demand in popular segments, like RTD cocktails, non-alcohol beers, energy drinks, sparkling water and better-for-you sodas for aluminum cans.

“We are even seeing coffee brands utilize the format to give consumers the on-the-go convenience for their favorite morning or midday pick-me-up,” he says. “The various size options for aluminum cans are a major reason brands continue to lean into this format. In addition to the standard 12-ounce can size, brands are seeking the 16-ounce, sleek or miniature 8-ounce (or smaller) can sizes to fit their beverage’s profile and consumer needs.”

Skotleski echoes similar sentiments, noting that brands are turning to aluminum more and more often to support sustainability commitments, “including improving the circularity of product lifecycles and reducing overall carbon footprint.”

In terms of sustainability and recycling goals, Skotleski says that the industry’s push toward more ambitious sustainability goals is “revealing more than ever” that aluminum cans inherently offer unparalleled sustainability benefits.

“When striving to make more responsible choices, both brands and consumers are finding it easier to rely on the beverage can, which already stands as a truly circular option without the major industry changes other substrates require,” he shares. “In fact, the beverage can boasts a 60-day turnaround from the point of consumption to the point at which it appears back on the shelf — and it is unique in that, through that recycling process, it experiences no loss of properties.”

Skotleski explains that the same beverage can will essentially be used six times a year, “which helps to explain why 80% of the aluminum ever produced is still in use today.” He proposes that such credentials are what drive beverage brands to appreciate and use aluminum at increasing rates.

“When setting a long-term Net Zero goal or other targets, the beverage can serves as a market-ready ally that falls into sustainability roadmaps with ease,” he says. “While the aluminum beverage can is already the most recycled beverage packaging in the world at a current rate of 69%, evolving regulations and industry goals are requiring the format to progress even further toward its full potential.”

Despite the achievements made around aluminum collection and recycling so far, Skotleski states that there are still educational and legislative challenges to overcome to increase rates to as close to 100% as possible.

“We work closely with industry organizations such as the Can Manufacturers Institute to educate consumers and metal packaging industry players around the benefits of aluminum cans, importance of proper recycling and the policy shifts needed to ensure the aluminum beverage can maintains its circular and sustainable attributes,” he explains.

CTI’s Wachter shares similar statements, noting that aluminum is infinitely recyclable without compromising quality.

“Industries are committing to circular economy practices, emphasizing closed-loop systems where recycled aluminum is incorporated into new packaging production,” he says. “The aluminum packaging market responds with innovations like easily recyclable designs and alternative coatings supporting recycling efforts.”

He notes that, in this landscape, CTI plays a vital role, engaging in initiatives to communicate eco-friendliness and responsibility through color-changing ink technology and its interactive effects on packaging graphics, which aim to educate consumers on properly recycling aluminum cans.

“There’s a collective effort to enhance sustainability in the aluminum packaging market, and we are actively contributing to this positive shift,” Wachter concludes.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!