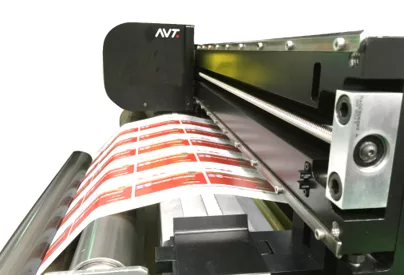

Print inspection solutions delivers inline measurement, quality reporting faster

Esko released its latest AVT innovation for print inspection: the SpectraLab XF. The SpectraLab XF delivers accurate, fast inline color measurement and quality reporting while helping packaging converters deliver measurements a “hundred times faster,” the company says. Unveiled at the recent Esko Innovation Summit, AVT SpectraLab XF is a unique inline color measurement solution based on a new, super-fast X-Rite sensor. With XRGA-compliance, AVT SpectraLab XF delivers the ability to measure during make-ready and production, ensuring color and quality consistency across the entire print cycle. It also provides color consistency and high-quality printing for packages and labels, helping to further brand recognition, trust and loyalty among consumers, it adds. The printer also enables converters to print to the numbers and monitor color accuracy at high speeds and volumes, something handheld manual measurement falls short of. Delivering accurate and automated color measurement for the full array of packaging applications, the AVT SpectraLab XF incorporates a new X-Rite spectral sensor and can measure a complete vertical color bar in a single repeat. Smaller, 4-5mm patches can be supported depending on press speed and a new LED lamp with M0, M1, and M2 correlates to offline inspection standards, it says.

Esko USA, 8535 Gander Creek Drive, Miamisburg, Ohio, 45342; 937/454-1721; www.esko.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!