How to pick a label applicator

Beverage packaging, packaging material essential considerations

Establishing an efficient labeling system can streamline operations, lower costs and lead to a more consistent product. When chosen correctly, a versatile label applicator will lead to a healthier bottom line.

But it’s not always easy to find the right applicator for your operations. Some businesses will require highly application-specific equipment, but for many, the right piece of equipment for applying pressure-sensitive labels can serve as an all-around productivity enhancer, greatly simplifying the process of bringing new products to market while maintaining consistency for a brand.

What they are and how they bring value

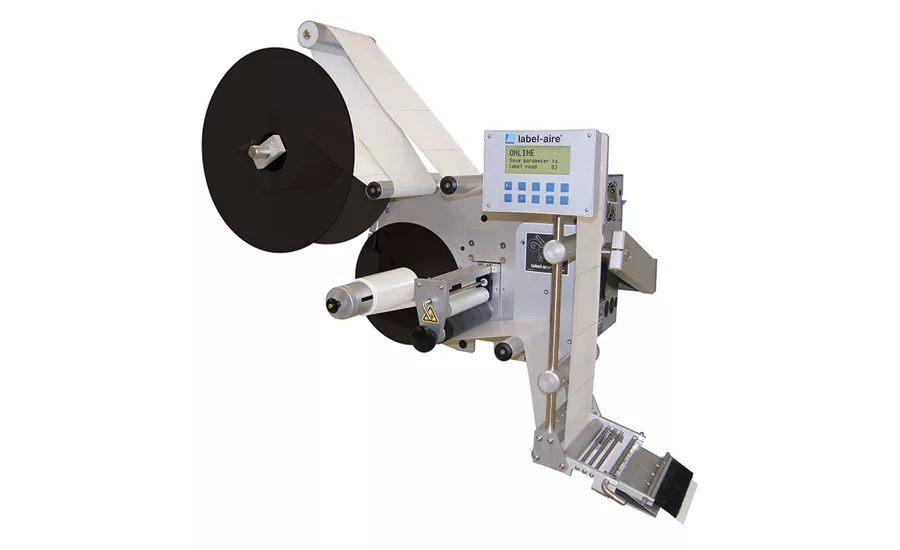

Label applicators are machines for automatically applying pressure-sensitive labels to products. Rolls of labels, which have either been pre-printed or are directly printed by the applicator, are loaded into the label applicator before being applied to product.

The popularity and heavy presence of label applicators in packaging operations stems from their ability to be customized to a manufacturer’s operations, while still remaining flexible enough to be configured to many different types of products and handling systems.

When compared with sleeve, cut-and-stack or mold labels, automated label applicators have the potential to drastically increase productivity and lower operating costs. A well-built, thoughtfully implemented label applicator that is easy to operate, fast and accurate will easily recoup its cost with time, providing a return on investment by reducing the need for manual labor while still increasing the rate of output. But it’s important to choose the right system in order to realize all of these benefits.

Types of label applicators

The following are some of the various label applicators available to manufacturers:

- Integrated, automated label applicators: These label applicators are directly integrated into the manufacturing operations, another step on the conveyor in an existing product handling system. These turnkey applicators can be set up in-line, where they’re automatically placed on a conveyor for labeling, or off-line, where they are manually added.

- Semi-automated label applicators: Semi-automated label applicators function via an operator who places a product into a fixture, or jig assembly, and then applies the label with a foot pedal or a sensor located within the machine. These label applicators often feature a tabletop design for added portability and ease-of-use, but usually are not integrated into an existing product handling system.

- Stand-alone label applicators: Stand-alone label applicators utilize a modular design for maximum versatility. They can be integrated into existing third-party product handling systems and can include a portable head mount. They also can be directly installed onto a conveyor or another machine.

Choosing the right label applicator

After becoming familiarized with the available label applicators, it’s important to know which factors of a label design should be most prominent when evaluating which applicator is the right choice. A labeling solution must, first-and-foremost, be cost-effective. That means that the equipment must perform at the necessary application speed, reduce labor costs and earn back its value with time.

But beyond those concerns, there are certain technical requirements that must be considered when selecting a label applicator. The following are some of those concerns:

- Product surface: It’s important to make sure that the label applicator can handle the shape of the packaging, whether it is flat, concave, convex or some other more irregular shape.

- Label sizes: In addition to shape, a label applicator’s length and width minimums and maximums must be able to account for the specific label dimensions.

- Label location capability: Once it’s been verified that a label applicator can accommodate the shape and dimensions of the brand’s label, it should be confirmed that it’s capable of reaching the correct surface of the product’s packaging, whether that be at the top, bottom, side or some combination of those.

- Material compatibility: The label applicator also needs to work well with the material on which the label is printed, whether that’s paper, film, foil or some other material.

- Application rate: A label applicator needs to keep up with the business. Application speeds, measured in products a minute, should conform to your present rates or offer an opportunity for improvement, providing that accuracy isn’t sacrificed.

- Accuracy requirements: Perhaps most importantly, a label applicator cannot come at the cost of accuracy. Continuously misplaced labels have the potential to reflect poorly on a brand and can even negate some of the production gains made by streamlining labeling operations.

Modernizing the labeling leg of the product handling procedure has the potential to deliver serious results for a business. There are a lot of factors to consider, and the right product should be supplemented by the advice of an experienced professional. But when the right product and expertise meet, label applicators have the power to deliver a real return on investment for brands. BI

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!