Fleet Maintenance Trends

David Kolman

New vehicles, engines, components and the uncertainty that goes along with any new truck technology is impacting equipment maintenance. Nevertheless, the goal of vehicle maintenance management remains unchanged: to come up with the best possible measures to maintain and service a vehicle to ensure maximum energy efficiency, optimum engine performance, the most efficient productivity and longest vehicle life.

Here is a look at some of today’s fleet

maintenance trends:

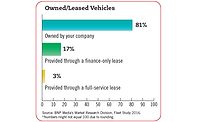

Full-Service Leasing — Any time a new technology is introduced in trucks, there is an

increased interest in full-service leasing. The reason: it can insulate

truck users from the uncertainty that goes along with new technology and

truck ownership. Plus, full-service leasing companies typically have

technicians trained in the new technology that handle vehicle maintenance

and emergency roadside service.

Telematics — The use

of telematics in vehicles is growing. Basically, telematics integrates

computing, electronic and wireless communication technologies. Vehicle

telematics systems are being used for such functions as real-time GPS

(Global Positioning System) vehicle tracking and positioning, navigation,

route optimization, dispatcher/ driver communications, mileage reporting,

toll-paying and remote vehicle monitoring and diagnostics.

Vehicle Life-Cycles — With the continued development of more reliable, longer-lasting

components, combined with the increase in total vehicle maintenance

management tools that allow specifically tailored maintenance programs,

fleets are extending their vehicle replacement cycles.

Maintenance — The

improvement in vehicle engineering and quality continues to lead to

decreased need for routine maintenance intervals and oil changes. With

advances in on-board technology, systems generate and store data, monitor

certain vehicle operating parameters and alert the driver to problems, plus

keep track of when scheduled maintenance is due.

Maintenance Information and Resources — As more powerful processing technology becomes available at

continually decreasing costs, fleets are increasingly developing and

implementing more advanced vehicle maintenance and service recordkeeping

systems and integrating them with improved fleet management systems. With

better information, they are gaining significant opportunities to improve

operations and make cost-effective decisions about whether to repair,

overhaul or replace vehicles.

Hybrid and Alternative Fueled Vehicles — The service and maintenance of these vehicles will become

more of an issue as greater numbers of them come into use. A hybrid vehicle

is one that combines two or more sources of power that can directly or

indirectly provide propulsion power. Alternative fuel vehicles run on a

number of non-petroleum-based fuels, including biodiesel, electricity,

methanol, ethanol, compressed natural gas and propane or liquefied

petroleum gas (LPG). Technicians will require additional training and new

tools to work on these vehicles, which can have such unique systems and

components.

Technology — Keeping

pace with changes in equipment, technology and legislation is becoming a

greater challenge. So, too, is the challenge to keep the existing workforce

up to par with required skills, and modifying the selection criteria used

in recruiting new employees.

Lifecycle Costing — As

fleets collect better information on maintenance and operating expenses,

vehicle lifecycle costing is taking on greater significance. Lifecycle cost

analysis is a process for evaluating the total economic cost of vehicle

ownership, taking into account all costs of acquiring, owning and disposing

of a vehicle over its useful fleet life.

Technicians — Fleets

continue to deal with a shortage of qualified technicians, and the

situation will become worse due to the demographic trends that underlie the

surge in demand. Experienced service technicians are retiring as fewer

people are choosing vehicle service as a career.

Keep in mind that vehicle maintenance begins when

buying new equipment. The choices you make at the beginning of a

vehicle’s life — selecting the appropriate make, model,

components, accessories, body and equipment for the particular application.

Then, for maximum uptime and lower overall lifecycle costs, set up —

and keep — an effective preventive maintenance program. BI

David Kolman is a veteran truck communicator, keynote

speaker and long-haul trucker. Commissioned as an Honorary Colonel on the

Kentucky governor’s staff for his work promoting traffic safety, he

actively participates in trade associations and reports news and

information about the trucking industry for broadcasting and print media.

Equipment news roundup

Kenworth introduced its

new K260 medium-duty cabover, a non-CDL truck with a gross vehicle weight

rating (GVWR) of 26,000 pounds.

The K260 has 63.2-inch bumper to back of cab (BBC)

dimension and is available in wheelbases of 189 and 210 inches, with either

an air or mechanical suspension. Its spacious 92.5-inch-wide cab easily

accommodates three. Doors open 90 degrees for comfortable entry/egress.

Power is supplied by a 220-horsepower PACCAR PX-6

5.9-liter diesel engine backed to a ZF overdrive six-speed transmission.

Axles are rated for 26,000 pounds — front 10,000

pounds; rear 21,000 pounds (4.56 ratio). Air disc brakes are positioned at

the front and rear.