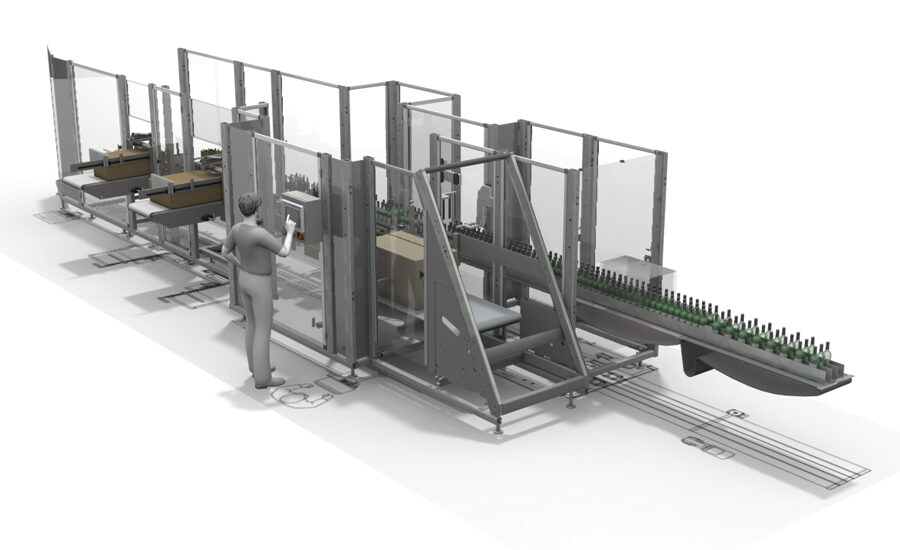

Capping it off

Douglas Machine Inc. announced the expansion of its case packing equipment for the wine industry with the offering of a fully integrated, single-cell top-load case packer for wine bottles. Integrated single-cell solutions include case erecting, loading, partition inserting and case sealing, with case print and label integration also available.

Douglas Machine Inc., 3404 Iowa St., Alexandria, Minn. 56308; 320/763-6587; douglas-machine.com.

Floating to the top

Fort Dearborn Co.introduced a floatable shrink-sleeve label that meets the Association of Plastics Recyclers’ (APR) recyclable guidelines for PET containers. The label has a lower density than traditional shrink-sleeve films that allows it to float and separate from the container during recycling, preventing contamination of the recycled products, the company says. Printed with recyclable-friendly inks and coatings, the label also offers shrink performance with optical film clarity, it adds. The new shrink sleeve can be applied using existing application equipment.

Fort Dearborn Co., 1530 Morse Ave., Elk Grove, Ill. 60007; 847/357-9500; fortdearborn.com.

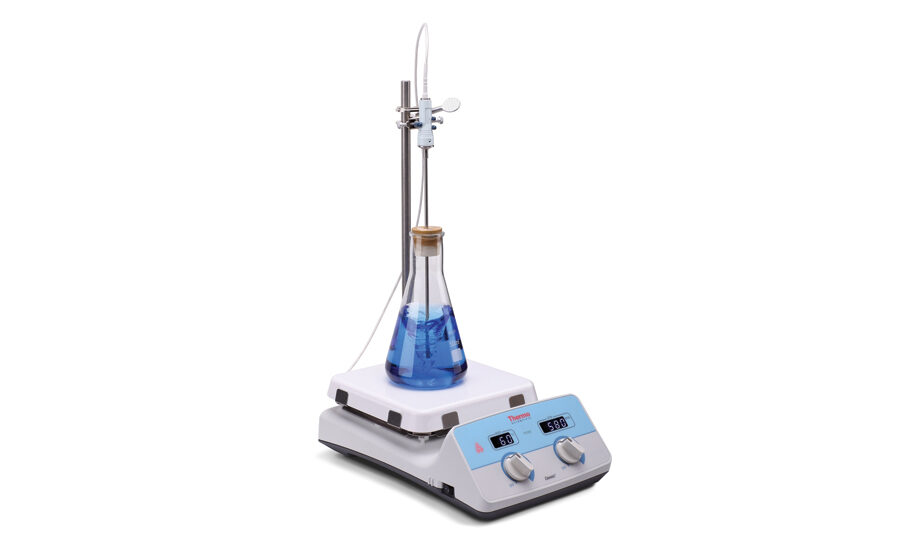

Stirring it up

Paul N. Gardner Co. Inc. introduced Cimarec+ Series Digital Hotplate Stirrers that offer precise, safe stirring control and exceptional temperature performance for microscale chemistries to production operations, the company says. Available in ceramic 4-, 7- and 10-inch sizes, the Cimarec+ stirrer features an easy-to-read LED display for heating and stirring and a raised display design that can be adjusted in 1-degree increments to protect electronics from spills and temperatures. Additional features include the StirTrac, which provides slow-speed stirring, consistent speed control, and a strong magnetic coupling with stirrer and stirring hotplate models. A Hot Top warning system also provides protection from accidental burns when the heating surface is above 122-degrees Fahrenheit.

Paul N. Gardner Co. Inc., 316 NE 1st St., Pompano Beach, Fla. 33060; 954/946-9454; gardco.com.

Mechanical mixer

Charles Ross & Son Co. offers a clean-in-place (CIP) ready Ultra-High Shear Mixer that is ideal for inline emulsification, particle size reduction and homogenization, the company says. It features a patented precisely machined rotor/stator that runs at speeds as fast as 11,000 feet a minute while forcing the product through concentric rows of intermeshing teeth, it adds. The combination of high fluid-velocity and close tolerances between interlocking channels in the rotor/stator subjects the product to intense mechanical and hydraulic shear in a single pass, it adds. CIP-ready models are equipped with a heavy-duty bearing assembly that comprises an oil sump with cooler and circulation pump driven by a washdown-duty motor with a mix chamber, rated for 150 psig at 250-degrees Fahrenheit. Other features include ease of cleaning and sanitization along with fast changeover and longer production runs.

Charles Ross & Son Co., 710 Old Willets Path, Hauppauge, N.Y. 11788; 800/243-7677; mixers.com.

Colder than ice

Frosty Cold Technologies launched its patented Frosty Cold Tech, a powdered coolant agent that transforms into a sub-freezing product when any type of water, even sea or ocean water, is added to it, the company says. The Frosty Cold Tech coolant is reusable inside its packaging, automatically regenerates via evaporation and can be refreshed and reused hundreds of times, it adds. An effective cold-chain solution, Frosty Cold Tech can provide basic refrigeration and food preservation help in underdeveloped countries and is applicable to industrial, medical and recreational industries. The non-toxic, 100 percent recyclable product can be adapted to any custom shape or volume, flexible or rigid packaging, and can be formulated to achieve any freezing point or desired temperature, the company says. When water is added to the Frosty Cold pack, which is pre-loaded with the patented coolant blend, it becomes colder than ice in 20 seconds and can maintain refrigerator temperatures for several hours, it adds. Frosty Cold is partnering with humanitarian organizations that serve underdeveloped regions and disaster areas.

Frosty Cold Tech, 7500 College Blvd., 5th Floor, Overland Park, Kan. 66210; 913/693-7230; frostycoldtech.com.

Sound sleeping

Kenworth Truck Co. offers a new 40-inch sleeper for truck models T880 and T680. The T880 sleeper is suitable in vocational applications that use straight trucks, such as petroleum haulers or the towing industry, and for tractors that transport flatbeds, lowboys or other trailers where length and weight are a factor, the company says. In the T680, a fuel-efficient bulk hauler, the sleeper provides a 260-pound weight savings compared with Kenworth’s 52-inch regional sleeper, it adds. Other features include a sleeping environment that provides more than 22 cubic-feet of storage space. Additionally, the sleeper has a 24-inch by 78-inch, liftable bunk with 90-degree tilt that offers easy access to storage underneath. Fleets and truck operators can choose between the Diamond VIT or Vantage interior, both of which feature coat hooks specifically designed to hold hardhats and coats. Both truck models now are available with Kenworth’s new PACCAR MX-11 engine, which produces as much as 430 horsepower and 1,550 pound-feet of torque.

Kenworth Truck Co., 10630 NE 38th Place, Kirkland, Wash. 98033; 425/828-5000; Kenworth.com.

Protective computing

Siemens released a new 19-inch Simatic HMI INOX Comfort Panel designed for hygienic area applications, the company says. The smooth, splinter-free stainless steel monitor features an easy-to-clean, 240-grit hairline finish with minimized gaps and grooves to protect against microorganisms and splinters, it adds. Other features include an analog-resistive touch sensor with a solid decorative membrane that provides protection for tightness and stability.

Siemens, 5300 Triangle Pkwy; Norcross, Ga. 30082; 800/241-4453; usa.siemens.com.

Leading the charge

Flux Power Holdings Inc., in partnership with Underwriters Laboratories (UL), unveiled new 24-volt Lift Pack lithium-ion battery pack models — Lift Pack S5 135 Ahe, LiFT Pack S5 250 Ahe and LiFT Pack S7 135 Ahe — that are used for Class III pallet-jack forklifts. The first UL 2271 Listed Light EV battery packs for use in electric battery powered industrial trucks, the lithium-ion battery packs also provide an alternative to the lead-acid batteries commonly used in the forklift market and deliver improved performance at a lower cost, the company says. UL 2271 certification is offered by UL for battery products, i.e. cell, module and pack, for use in a variety of light motive or transportation-related applications. UL assesses the ability of the battery packs to meet the standard requirements, as well as electrical, mechanical and environmental testing evaluated per the the company’s compliance criteria. Flux will begin shipping its UL 2271 lithium batteries for electric trucks in the second quarter of 2016.

Flux Power Holdings Inc., 985 Poinsettia Ave., Vista, Calif. 92081; 877/505-3589; fluxpwr.com.

Distributing power

Larson Electronics LLC released its temporary power distribution system with a 480-volt transformer that provides a safe, reliable way for operators in industrial settings to independently tap into and utilize power sources away from the work area, the company says. The three-phase transformer can be stepped down to single-phase at 120 volts AC and three-phase at 208Y-volts AC, it adds. One hundred feet of Type W line-in power cord is included to connect the substation to a primary 480-volt, three-phase power supply, and the secondary current is wired to a 120/208Y, three-phase, 100-amp load center with a main breaker for circuit protection, it adds. Mounted to a standard steel dolly-cart-style frame, the transformer and distribution assembly provide substation mobility and a center point lift eye allows for easy lifting with cable or chain hooks, according to the company.

Larson Electronics LLC, 9419 E. U.S. Highway 175, Kemp, Texas 75143; 800/369-6671; larsonelectronics.com.

Trouble-free performance

Butler Automatic Inc. introduced its SP1 Series Automatic Film Splicer, which increases efficiency in packaging operations by eliminating the packaging line downtime caused by manual film roll changes, the company says. The device senses the diameter of the expiring roll of film and automatically splices the end of each expiring roll onto the new roll. The SP1 Automatic Film Splicer can run at speeds as fast

as 600 feet a minute, it adds.

Butler Automatic Inc., 41 Leona Drive, Middleborough, Mass. 02346; 508/923-0544; butlerautomatic.com.

A smart camera

Cognex Corp. offers its In-Sight Micro 8000 series smart camera, a new line of ultra-compact, standalone vision systems that delivers industry-leading vision tool performance at PC speeds using a traditional “dumb” GigE Vision camera, the company says. As line speeds increase, manufacturers demand greater accuracy, larger fields of view and faster vision tool performance — all without a PC on the factory floor, it adds. Like all In-Sight vision systems, the compact camera is set up with the In-Sight Explorer software that combines the step-by-step EasyBuilder setup with spreadsheet view for greater control, the company says. Other features include power over Ethernet, minimizing cabling that enables the vision systems to integrate into tight spaces on robots and hard-to-reach machinery, it adds.

Cognex Corp., 1 Vision Drive, Natick, Mass. 01760; 855/426-4639; cognex.com.

Saving on seals

Wanner Engineering Inc. offers an upgrade to its Hydra-Cell D10 Series seal-less pumps. Previously rated at 1,000 psi (69 bar) maximum discharge pressure, the new Hydra-Cell D10 models with metallic pump heads now can operate as much as 1,500 psi (103 bar) discharge pressure, the company says. Used for a wide range

of processing applications and in manufacturing plants, Hydra-Cell D10 models have a flow capacity of 4.26 gallons per minute (gpm) with a motor speed of 790 revolutions per minute (rpm) when performing at the higher pressure rating, it adds. Additionally, the pumps contain no mechanical seals, cups or packing to leak, wear or replace, which enables it to handle viscous fluids and abrasive particulates as large as 500 microns in size. In the event of a closed or clogged inlet condition, the D10’s patented Kel-Cell technology will enable it to indefinitely run-dry without damage to the pump, it adds.

Wanner Engineering Inc., 1204 Chestnut Ave., Minneapolis, Minn. 55403; 612/332-5681; hydra-cell.com.

Refilling right

Fountain Master LLC introduced its CO2GO Filling Station, an automated vending machine that economically refills CO2GO branded CO2 cylinders. Similar in size and function to a Redbox machine, CO2GO Filling Stations can be placed in locations easily accessible to the public, including local grocery stores, pharmacies and food markets, the company says. The cylinders are compatible with the Fountain Master cold-beverage system as well as other countertop beverage systems, including SodaStream sparkling beverage makers and Samsung refrigerators. The product is expected to launch regionally this fall.

Fountain Master LLC, P.O. Box 7348, Freehold, N.J. 07728; 732/761-8090; fountainmaster.com.