A new look

In order to meet users’ more stringent requirements for cleaning and disinfection, ContiTech has further developed its beer and drink hoses’ properties to improve their temperature resistance and flexibility. Following testing in extreme usage conditions, the company has decided to initiate series production and discontinue its previous-generation hose. The new Purple Snake hose features a taste- and odor-neutral, high-performance special inner lining as well as new branding: a blue spiral line continuously marked in white that displays the brand and manufacturer name and all of the national and international approvals the hose has received. This shows the user at first glance that the hose meets applicable regulations and is food safe. Additionally, the new marking has a quick-response code for calling up more detailed information on construction and properties, cleaning and disinfection, and the specific hose’s delivery program. ContiTech plans to roll out this new branding on all of the hoses in its portfolio.

ContiTech North America Inc., 136 Summit Ave., Montvale, N.J. 07645; 800/654-0974; contitech.us.

Savings heat up

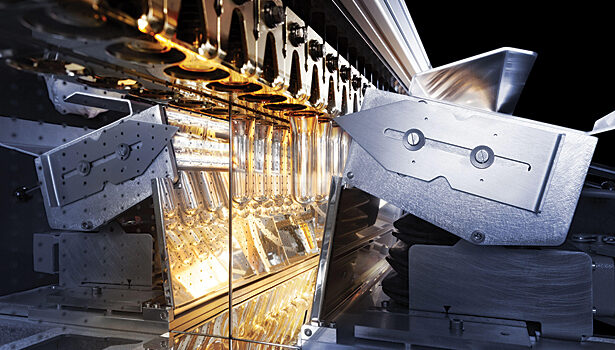

The beverage industry continues to seek lighter PET bottles that remain stable and ensure the quality of the product inside. KHS is taking another step toward reducing bottle weight while maintaining quality with its new line heater. This heating module is designed to be integrated into the rear heater area of a KHS stretch blow molder like its InnoPET Blomax Series IV stretch blow molder, which uses near infrared (NIR) to heat preforms. With NIR, the heat penetration of the preform wall is extremely intense — a feature further enhanced by feeding the preform through a closed heating chamber with all-around reflection. This enables an ideal heating profile to be applied to the preforms while saving energy, the company says. During the controlled heating process, the neck area of each preform is shielded to prevent deformation. Because the neck area is so critical, there is an extremely temperature-sensitive zone directly below the support ring. This must be protected against heat toward the neck yet ideally heated with the utmost precision toward the preform body in order for the PET material in this area to be perfectly stretched, the company explains. KHS’ line heater includes a parabolic mirror that produces a defined, precisely adjustable ray of heat for focused heating. In this way, the additionally heated PET material can be transferred to the bottle body during the stretching process, and lighter preforms can be used for the manufacture of PET bottles.

KHS USA, 880 Bahcall Court, Waukesha, Wis. 53186; 262/797-7200; khs.com.

Rugged reader

Cognex Corp. announced the next generation of its handheld direct-part-mark (DPM) barcode readers. The DataMan 8600 series builds upon its DataMan 8500 handheld barcode reader and combines industry-tested 2DMax+ algorithms and patented Cognex UltraLight technology to read the most challenging DPM codes on the widest range of materials and surfaces, the company says. Additionally, the DataMan 8600 series handheld readers provide Ethernet communication with industrial protocols, enabling seamless integration with factory automation equipment, as well as field interchangeable communication modules that allow readers to be configured to meet customer-specific communication requirements. Available with both corded and wireless communication modules, the DataMan 8600 series supports industry-standard communications including USB, RS-232 and Bluetooth wireless communication to an intelligent base station. Designed for harsh work environments, it also has a rugged industrial design as well as a range of industrial cables and accessories to support the product.

Cognex Corp., 1 Vision Drive, Natick, Mass. 01760; 855/426-4639; cognex.com.

Finding the right mix

Ross Dual-Shaft Mixers enable efficient powder dispersion and convenient batch temperature control in the manufacture of low- to high-viscosity formulations, the company says. For example, its 100-gallon Dual Shaft Mixer Model CDA-100 uses two heavy-duty, independently driven agitators, a high-speed disperser and a two-wing anchor to deliver a wide range of shear levels and flow patterns that can adapt to the varying rheologies of solutions, pastes, gels, suspensions and slurries all throughout the mixing cycle, it says. The sawtooth disperser blade draws solids into a powerful vortex and disintegrates dry agglomerates as the low-speed anchor continuously stirs the batch, it explains. This combination of mixing actions ensures a thorough turnover as fresh product is constantly coming in contact with the disperser and materials around the periphery are continuously being scraped off the vessel surfaces, the company adds. In addition, the mixer is equipped with an air/oil hydraulic lift for raising and lowering the agitators. All wetted parts are stainless steel 316, including the mixer cover, which has 3-inch sight/charge ports and a connection for a vacuum. The disperser and anchor are driven by 15- and 10-horsepower explosion-proof inverter duty motors, respectively, and both agitator shafts utilize single mechanical seals with Viton O-rings.

Charles Ross & Son Co., 710 Old Willets Path, Hauppauge, N.Y. 11788; 800/243-7677; mixers.com.

Blowdown control

Spirax Sarco released its BCV43 series blowdown control valves in three-quarters of an inch and 1.5-inch line sizes. This new range of BCV43 blowdown control valves are based on the Spira-Trol platform and are designed to maintain total dissolved solids at an optimum level and keep blowdown to a minimum, thus maintaining a healthy steam and condensate system and conserving water and energy, the company says. The BCV43 blowdown control valves are suitable for a wide variety of applications where boilers are operated unsupervised for 24- to 72-hour periods and have been engineered to minimize seat erosion, ensuring consistent, tight shut-off.

Spirax Sarco USA, 1150 Northpoint Blvd., Blythewood, S.C. 29016; 800/575-0394; spiraxsarco.com.

Mini me

Cat Lift Trucks introduced a new 7,000-pound-capacity model to its large electric pneumatic tire lift truck series, which can handle loads as heavy as 11,000 pounds. The new 2EPC7000 lift truck features industry-leading lift speeds and increased energy efficiency for greater productivity, the company says. Overall, the expanded 2EPC7000-2EPC11000 range of lift trucks offers three-phase AC motors engineered for maximum efficiency and performance, responsive acceleration and braking, and controlled travel speeds on ramps; batteries that can last up to two shifts; 500-hour extended service intervals for greater uptime; and additional options such as pin-code access, ergonomic seats, cold storage or tropics modifications, and closed cabins.

Cat Lift Trucks, 2121 W. Sam Houston Parkway North, Houston, Texas 77043; 713/365-1000; cat-lift.com.

Adding some fizz

In order to meet growing demands for seltzer and carbonated flavored waters, TechniBlend developed its TB-ILC Inline Carbonation System. Based on extensive research, development and experience with how carbon dioxide is absorbed into a beverage, the TechniBlend system utilizes unique injection, mixing and absorption techniques to ensure that carbon dioxide is fully mixed and properly absorbed into a beverage. TechniBlend offers several different models for beverage product needs. Some models use coriolis mass flow meters to measure product and carbon dioxide in order to deliver carbon dioxide accuracy and precision as well as conventional spray diffusion and tank carbonation systems, which deliver reliable and consistent carbonation control at a more economical price point. In all cases, the TechniBlend system provides superior product and pressure control to guarantee that carbonation levels and saturation pressures are accurately maintained for optimal product stability, the company says.

TechniBlend Inc., N8 W22275 Johnson Drive, Waukesha, Wis. 53186; 262/584-4408; techniblend.com.

Small-business size

To meet the needs of craft brewers and small wineries and distilleries, Standard-Knapp designed a new bottle-handling tool. The EZ Picker is engineered for quick and easy handling of empty and full glass bottles. The system is available in a variety of sizes, including the standard 12-bottle carrier with notched centers for six-pack loading, carriers for 7-ounce to 40-ounce beer bottles, and 750-ml and 1-, 1.5- and 1.75-liter wine and liquor bottles in numerous arrangements. It also can assist with building rainbow packs, the company says. In addition, The EZ Picker weighs less than 4 pounds and features a robust stainless steel construction and smooth gripping action for gentle product handling.

Standard-Knapp Inc., 63 Pickering St., Portland, Conn. 06480; 860/342-1100; standard-knapp.com.

Checking all sides

Eagle Product Inspection created a new advancement in beverage product and packaging inspection with its Eagle Tall Pro XSDV X-ray system. Featuring dual side-view detection technology, the X-ray system offers high-speed inspection of cans, bottles, jars and other upright packaged products. It also provides superior sensitivity by producing two beams with a single X-ray generator. This allows different sides of each package to be inspected as it passes through the search head, maximizing sensitivity levels by detecting up to 50 percent smaller contaminants than traditional machines, the company says. The combination of high-speed inspection and its newly added reject functions makes the system ideal for beverage manufacturers with limited space, it adds.

Eagle Product Inspection, 6005 Benjamin Road, Tampa, Fla. 33634; 877/379-1670; eaglepi.com.

Ready for oversized loads

Designed to offer added support needed to lift large, long or weighty objects, Beacon Industries offers its brand of BFE series fork extension sleeves for fork trucks. Constructed from welded steel and featuring casted steel tips, these units are made to withstand the constant wear and tear of industrial applications, the company says. Extenders can be secured to the forks through a loop- or pin-style attachment system. When evenly distributed, the weight capacity of these units is approximately 4,000 pounds. Hot dipped galvanized and other specialty finishes can be applied to make fork extenders more resistant to corrosion. Fork truck operators can attach or remove extensions from the rack without ever leaving the vehicle’s controls, making these items useful and efficient additions to any facility’s current fleet of forklift trucks, it adds. Beacon also offers storage racks for forklift extensions to hold and safeguard them while not in use.

Beacon Industries Inc., 12300 Old Tesson Road, St. Louis, Mo. 63128; 314/487-7600; beacontechnology.com.

Starting off clean

To help homebrewers and microbrewers get their beer production started, EJ Beverage, a division of Eldon James Corp., offers a draft line conversion kit with PVC-free and antimicrobial tubing. The Brew Ultra Draught Line Conversion Kit is specially designed for home-dispensing systems. The kit includes PVC-free and antimicrobial coiled tubing for a beer dispensing line and a coiled length of PVC-free clear tubing with a red stripe for the gas line. The beer line was developed and tested to help prevent the buildup of biofilm within the tubing walls. The gas line was co-developed with New Belgium Brewing to address concerns of unseen mold buildup and hidden valve failures that could cause product or cleaner to back up in the gas line, the company says.

Eldon James Corp., 10325 East 47th Ave., Denver, Colo. 80238; 970/667-2728; eldonjames.com.