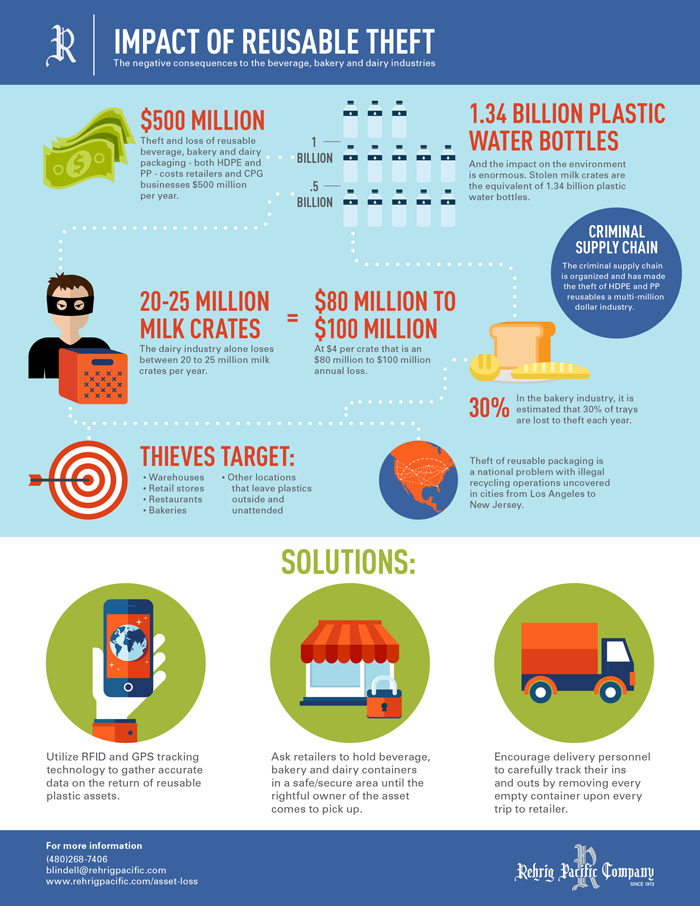

Despite increasing awareness, milk crates, plastic pallets, bakery trays, beverage shells and other containers made from high density polyethylene (HDPE) and polypropylene (PP) are disappearing at a rate that costs retailers and CPG businesses $500 million per year. Ultimately, consumers end up paying this $500 million annual expense in the costs of goods purchased.

The dairy industry alone loses roughly $80 million - $100 million each year, and the replacement cost is $4 per crate. The math is simple, 20 million to 25 million milk crates go missing, mainly from theft. In the bakery industry, it is estimated that 30 percent of trays are lost to theft each year.

And it is no mystery why. A thief at the first stage of this criminal supply chain can earn approximately 11 cents per pound for a stolen container. Their customer—an illegal recycler— grinds these stolen HDPE products into pellets and can export it for upwards of 50 cents per pound. Consider that $4 crate that was stolen and realize that it sells for at least $1.25 on the black market. Milk crates alone may represent $20 to $25 million in the illegal trafficking of HDPE.

In its white paper “Going Green Without Going into the Red,” Rehrig Pacific Co., Pleasant Prairie, Wis., highlights efforts and strategies that organizations and businesses are implementing to reduce theft and loss. One organization— COMBAT (Control of Missing Baskets and Trays)— a multi-industry collaboration of beverage, bakery and dairy manufacturers that are working to educate drivers and customers on how to better manage assets as well as getting legislation enacted to make penalties stiffer for criminals, Rehrig Pacific Co. says.

Rehrig Pacific Co. notes that every business should be incented to solve this problem. Why? Because the added expense of acquiring replacements reduces profits and ultimately costs the consumer in higher prices. And, businesses that reduce theft of reusable packaging gain a competitive advantage over those that do not, it adds.

The company says it believes it is the time to not accept the loss of these assets as a cost of doing business, accelerate strategies to reduce theft and diminish the financial incentive to steal. How?

First, the company says that businesses need to work together through organizations such as the American Beverage Association, Food Marketing Institute, the American Bakers Association and the Grocery Manufacturers Association to develop best practices, the company says.

Second, drivers must be trained to realize that tracking containers is part of their job description. Third, grocers need to be educated on the best methods to prevent abandonment and protect and store reusable assets, and that if they fail to keep them safe, they are in fact complicit in the crime, the company says. Thieves see idle containers not as someone’s property but something left for anyone to take, it adds.

Fourth, begin integrating technology including RFID and GPS to gain accurate and actionable information that can aid in controlling losses and identify locations that need to improve their behavior, it says. And finally, make law enforcement and lawmakers aware of the problem and partner with them to enact stiffer penalties.

Shrink is always factored in as a cost of doing business, and as businesses realize the benefits of reusable packaging to reduce shrink, they will reduce unsaleables, improve productivity, diminish environmental footprint, become more sustainable, lower operating expenses and engage with consumers, they also need to develop effective strategies to reduce shrink in their reusable assets, Rehrig Pacific Co says. There are at least 500 million reasons why.

(Click here for full-size image)