Crafting packaging solutions

Combi Packaging Solutions LLC announced the release of a new packaging machine that will allow craft brewers to maintain their hand craftsmanship while reducing labor costs and increasing throughput to quickly get products to distributors and retail shelves, the company says. Designed to alleviate the tedious task of hand-erecting four- and six-pack carriers, Combi developed its multi-functioning BrewPack machine that erects four- and six-pack carriers along with the regular slotted carton master case and then case packs the carriers, creating a bottle-ready case, it adds. Additionally, it offers a customizable ErgoPack ergonomic hand-packing station that contains a six-pack carrier dispenser and recirculating conveyor for semi-automatic bottle case packing. Both machines will be operating at BrewExpo America in Philadelphia, May 4-6.

Combi Packaging Systems LLC, 5365 E. Center Drive NE, Canton, Ohio 44721; 800/521-9072; combi.com.

Powerful refraction

Reichert Technologies added two new refractometers to its line of analytical instruments: the AR9 Refractometer and the AR5 Refractometer. Accurate, reliable and tough enough for the most demanding applications, the new AR Series Refractometers measure a wide variety of fluids, including juices, beers, engine coolants, pharmaceuticals and more, the company says. The top-of-the-line AR9 refractometer is resilient, durable and precise with measurement accuracies of 0.00002 refractive index (RI) and 0.02 percent Brix. With a built-in Peltier thermostat, the AR9 also controls the temperature at the sample interface to an exactness of 0.03 degrees Celsius, it adds. Built for research and development projects, the AR9 provides the mandatory data needed with a YAG (Yttrium Aluminum Garnet) prism, the hardest prism available, along with a 7-inch color touch-screen universal display, it adds. The economical AR5 refractometer includes Peltier temperature control, a precise measuring RI with results accurate to 0.0001 RI and 0.05 percent Brix, and is the ideal instrument to perform routine measurements with standard scales, according to the company. Other features include a robust design and a sapphire prism that ensures reliable operation.

Reichert Technologies, 3362 Walden Ave., Depew, N.Y. 14043; 888/849-8955; reichert.com.

PET processing made easy

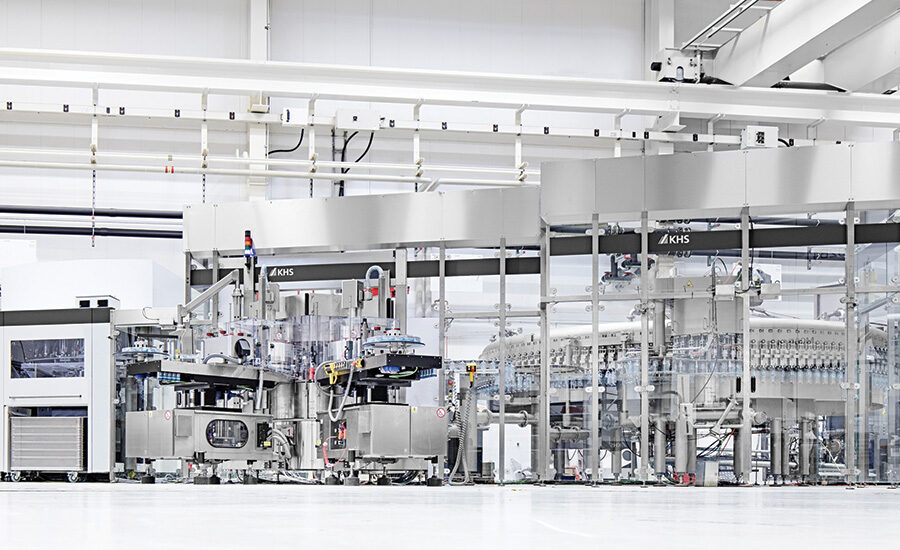

KHS launched a new filling and packing system — the KHS InnoPET TriBlock — for bringing multifunctional PET bottles to market. The system incorporates a stretch blow molder, labeler and filler. With consistent neck handling, the InnoPET TriBlock also enables lightweight PET, including a 0.5-liter bottle weighing notably less than 8 grams, to be easily processed, the company says. In addition, the system utilizes an innovative pre-glued technology that eliminates hot-melt vapors, it adds. Other features include easier bottle handling and improved efficiency and hygiene, as there is no need for air conveying segments. Additionally, KHS also provides a new option to integrate a labeler into the block so that containers are fully conveyed within one machine. It also saves space, energy and manpower costs because it can be operated by one person, it adds.

KHS USA, 880 Bahcall Court, Waukesha, Wis. 53186; 262/797-7200; khs.com.

A dairy-good solution

Douglas Machine Inc. announced that its Vectra Cartoner provides market versatility, particularly for the dairy industry. The equipment’s sanitary design is ideal for packaging fresh and extended shelf life milk products into multipack cartons, the company says. The Vectra platform handles products in gable-top cartons, PET bottles and aseptic bricks, it adds.

Douglas Machine Inc., 3404 Iowa St., Alexandria, Minn. 56308; 320/763-6587; douglas-machine.com.

Specialty designs

NORD Gear Corp. announced the recent expansion of its machining department and the flexibility, customization and commitment NORD Drivesystems offers to its customers. NORD’s range of drive equipment includes helical in-line, helical shaft-mount, helical-bevel, helical-worm, worm gear units, large industrial gearboxes, AC motors and AC Vector drives with as much as 250 horsepower, the company says.

NORD Gear Corp. USA, 800 Nord Drive, Waunakee, Wis. 53587; 888/314-6673; nord.com.

Withstanding high temperatures

Baumer Ltd. added five new product variants to its CleverLevel series, which includes a compact level-switch with frequency-sweeping technology in a miniaturized design for extra flexibility at high temperatures, the company says. Other features include a cooling neck for high temperature applications and a longer version for improved level detection in bulk media. The maintenance-free device is built to withstand long-term temperatures as high as 200 degrees Celsius, it adds. The 82- and 250-millimeter designs are suitable for tanks with thick layers of insulation and cone-bottom kettles. They also can be used with highly viscous or bulk media to prevent faulty switching operations and unwanted downtime for enhanced equipment productivity.

Baumer Ltd., 122 Spring St., Unit C-6, Southington, Conn. 06489; 860/621-2121; baumer.com.

Mobile protection

RAM Mounting Systems, a division of National Products Inc., introduced IntelliSkin, a protective device case that simplifies the frequent docking and undocking of smartphones and tablets common in rugged trucking and field applications, the company says. IntelliSkin provides standard charging contacts to prevent damage to iPhones, iPads, and Samsung phones and tablets, while featuring an integrated power connector that is compatible with any global docking system (GDS) technology, it adds. RAM Mounts’ GDS platform provides compatibility with many different devices and offers docking stations with scalability. In addition, GDS docking stations allow access to keyboards, monitors, speakers, hard drives and other USB devices by plugging in a connectivity hub to the back of the dock, it adds.

National Products Inc., 8410 Dallas Ave. S., Seattle, Wash. 98108; 800/497-7479; rammount.com.

Blending precision

Alfa Laval offers a rotary jet mixer that quickly and efficiently handles liquid and powder mixing, gas dispersion, and clean-in-place (CIP) tank cleaning, without requiring separate pieces of equipment for each process, the company says. The rotary jet mixer combines high blending precision with minimized mixing times, saving as much as 50 percent in energy requirements, it adds. Based on rotary jet head technology, it can be used in tanks between 100 and 800,000 liters. Equipped with two or four nozzles, the rotary jet mixer is positioned below liquid level in the tank. Liquid is withdrawn from the tank outlet by a pump and circulated through an external loop to the mixer, the company says.

Alfa Laval Inc., 5400 International Trade Drive, Richmond, Va. 23231; 800/558-4060; alfalaval.us.

Meter measurement

Omega Engineering Inc. released its transit time ultrasonic flow meter, a non-intrusive flow measurement for clean water and chemicals. The Omega FDT7000 series offers easy installation because its snap and clamp-on pipe transducer body sensors do not come in contact with the internal liquid, the company says. The technology has several inherent advantages over alternate ultrasonic devices including low-cost, easy installation, no pressure head loss, no moving parts to maintain or replace, no fluid compatibility issue, and a wide measuring range that ensures reliable readings, it adds. The FDT7000 is CE approved, NEMA 3 (IP54) protected and is designed to work on PCV-, PP- and UPVC-pipe systems.

Omega Engineering Inc., One Omega Drive, Stamford, Conn. 06907; 888/826-6342; omega.com.

Sanitary processes

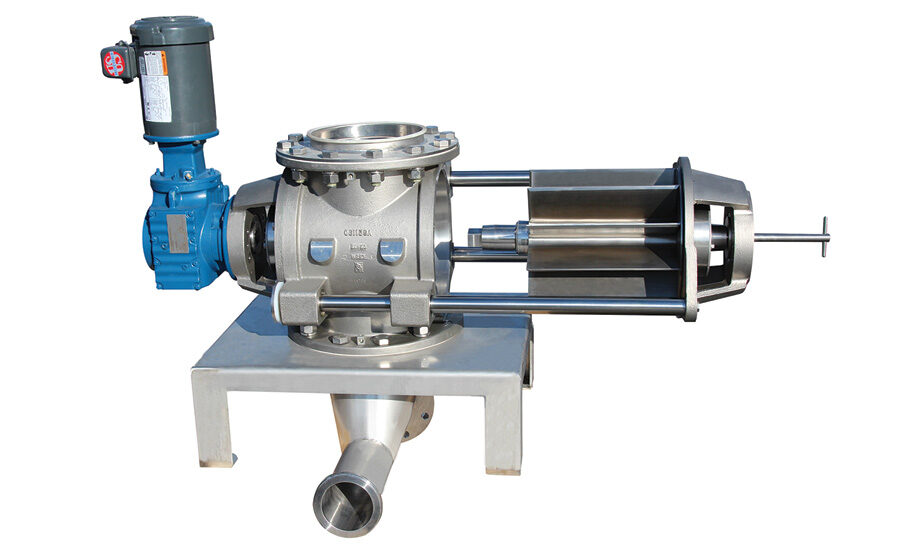

Schenck Process launched a new Global Cleanable Airlock (GCA) ideal for applications where dry, raw or finished products are being handled and inspection or system clean-out are required. Because the GCA is designed for high process rates and offers a number of features suited for sanitary processes, the airlock is specifically suited for food and pet food applications, the company says. The GCA is available in two models: a standard unit and a demountable unit. The standard model is a round-inlet, round-outlet rotary valve, which incorporates seals and product contact surfaces. The demountable unit is designed with a rail system that simplifies removal of the endplate/rotor assembly from the housing providing access to the internal valve cavity, rotor pockets and all other product contact areas for quick and easy cleaning, the company says.

Schenck Process, 746 E. Milwaukee St., Whitewater, Wis. 53190; 816/891-9300; schenckprocess.com.

Lubricated braking control

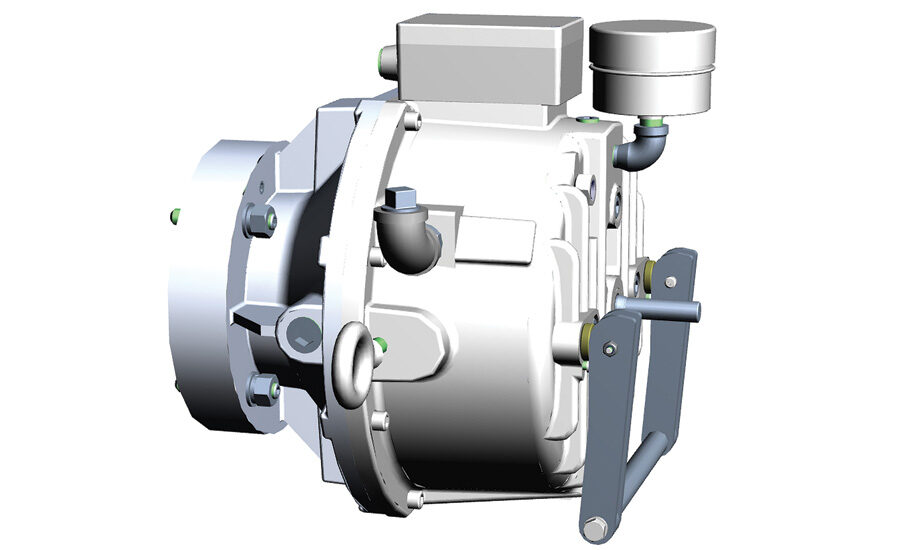

Force Control Industries unveiled its new MagnaShear hazardous duty brakes, which employ oil shear technology to provide longer service life with virtually no maintenance or adjustment, the company says. The motor brakes are ideal for applications where the motor is reversed for each cycle, such as in cranes, winches and hoists as well as ship and railcar loader/unloader conveyors, and tippers and sweep samplers, the company says. Additionally, the MagnaShear motors now meet Class I and Class II Div 2 specifications. Available with spring-set torque ratings from 3 to 900 foot-pounds, MagnaShear motor brakes can be sized to the correct torque independent of the motor frame size or horsepower, it adds. The motor includes quick-mount features for quick and easy mounting to drive motors in NEMA frame sizes 56 to 405. Proven oil shear technology transmits torque between lubricated surfaces — thereby eliminating wear on friction surfaces, providing longer service life with no maintenance or adjustment, according to the company. Additionally, the patented fluid recirculation system dissipates heat build-up, a common problem in dry braking systems, it says.

Force Control Industries, 3660 Dixie Highway, Fairfield, Ohio 45014; 513/868-0900; forcecontrol.com.

Stirring it up

Paul N. Gardner Co. Inc. introduced Cimarec+ Series Digital Hotplate Stirrers that offer precise, safe stirring control and exceptional temperature performance for microscale chemistries to production operations, the company says. Available in ceramic 4-, 7- and 10-inch sizes, the Cimarec+ stirrer features an easy-to-read LED display for heating and stirring and a raised display design that can be adjusted in 1-degree increments to protect electronics from spills and temperatures. Additional features include the StirTrac, which provides slow-speed stirring, consistent speed control, and a strong magnetic coupling with stirrer and stirring hotplate models. A Hot Top warning system also provides protection from accidental burns when the heating surface is above 122 degrees Fahrenheit.

Paul N. Gardner Co. Inc., 316 NE 1st St., Pompano Beach, Fla. 33060; 954/946-9454; gardco.com.

Trouble-free performance

Butler Automatic Inc. introduced its SP1 Series Automatic Film Splicer, which increases efficiency in packaging operations by eliminating packaging line downtime caused by manual film roll changes, the company says. The device senses the diameter of the expiring roll of film and automatically splices the end of each expiring roll onto the new roll. The SP1 Automatic Film Splicer can run at speeds as fast as 600 feet a minute, it adds.

Butler Automatic Inc., 41 Leona Drive, Middleborough, Mass. 02346; 508/923-0544; butlerautomatic.com.

Filtration fineness

Argonide Corp. offers CoolBlue, an under-counter water purification system that incorporates advanced microbiological purifier performance that meets the U.S. Environmental Protection Agency’s Guide Standard for Microbiological Purifiers as tested and certified by the Water Quality Association (WQA), the company says. Effective for water with a high pH level, the three-stage filtration process utilizes Argonide’s original NanoCeram technology for improved taste and reduction of soluble contaminants. The system’s last step features a patent-pending DEAL filtration media that attracts, captures and retains submicron particles, including bacteria and viruses, to offer the cleanest water, it adds.

Argonide Corp., 291 Power Court, Sanford, Fla. 32771; 407/322-2500; argonide.com.