New door capabilities

Aleco, a division of ES Robbins Corp., announced the launch of its AirFlow Mesh Bug Barrier Door by Aleco. The AirFlow Mesh Bug Barrier Door allows air ventilation but also keeps insects and debris out of work areas while providing additional security, the company says. It provides a 65 percent shade factor helping to keep facilities cooler longer by significantly reducing heat from the sun and allowing light in. AirFlow helps meet U.S. Food and Drug Administration requirements, improves building appearance and is available in seven colors, it says.

• Aleco, 2720 East Avalon Ave., Muscle Shoals, Ala. 35661; 800/633-3120; aleco.com.

Servo-driven system

BBULL USA offers its Brush-Off Servo (BOS) technology that provides guaranteed upright rejection of defective standard round glass containers. The compact BBULL BOS is complete with tracking controls to allow simple integration onto any bottling line or production equipment to increase line efficiencies and reduce waste associated with fallen containers in the rejection area, according to the company. The new BOS uses a servo-controlled cam to divert product smoothly to an adjacent conveyor or motorized reject table. With only one moving wear part, the system offers reliability and provides savings in maintenance cost compared to conventional devices, the company says.

• BBULL USA, 260 Scarlet Blvd., Oldsmar, Fla. 34677;

813/855-1400; bbullusa.com.

Commercial filters

Genesis Water Technologies Inc. introduced its GWT series commercial/industrial ultrafiltration system solutions, which incorporate advanced ultrafiltration rigid membrane technology to provide cost-effective, high-performance output for a wide range of water filtration and reuse applications throughout the food and beverage industries, the company says. These systems are custom built for high flow rate applications of 100 gallons a minute or higher and can handle a range of total suspended solids, biochemical oxygen demands, chemical oxygen demands and turbidity, while still providing consistently high product water recovery rates. These flexible systems are cost effective, provide lower maintenance and operating costs, and are available in different configurations to meet clients’ specific filtration requirements, the company says.

• Genesis Water Technologies Inc., 555 Winderely Place,

Suite 300, Maitland, Fla. 32751; 877/267-3699; genesiswatertech.com.

Case sealers

Eagle Packaging Machinery offers a wide range of case sealers that use glue or tape to seal cases. For glue applications, Eagle offers three models: the CS-BD (belt-drive) for typical case sealing applications for corrugated cases; the CS-BNB (bag-in-box) to provide added protection to the bagged product inside the case from being punctured by using a full-overlap flap

case where the seam is on the edge of the case; and the CS-FB (flight bar) case sealer for tall cases that tend to tip on a belt conveyor as well as for light or heavy cases that require a positive push through the machine. All EZglue case sealers run at speeds of 40 cases a minute and can apply glue on all flaps or glue between the outside major and minor flaps, the company says. With a range as small as 6-inch by 6-inch by 6-inch and up to 18 inches wide by 20 inches deep and any length, EZglue series case sealers can handle very small light cases to large heavy cases, the company says. For tape applications, Eagle offers three models: the CS-12 with two side belts and the CS-12H with two side belts and one top belt for heavier cases. For a fully automatic solution, the Automatic Case Sealer closes all flaps prior to sealing. EZtape case sealers operate at speeds up to 12 cases a minute and are easily adjusted for different case heights and widths. Using 2-inch- or 3-inch-wide tape, these tape sealers can work independently or in a production line and also offer a case range of 6-inch by 6-inch by 6-inch and up to

18 inches wide by 20 inches deep and any length.

• Eagle Packaging Machinery LLC, 4760 NW 128th St., Miami, Fla. 33054; 305/622-4070; eaglepm.com.

Heavy-duty door

TMI LLC developed a rugged and durable swinging door — the Mega-Pro Heavy Duty (HD). The new Mega-Pro HD is designed to handle the heaviest levels of forklift and mechanized traffic, while effectively separating a building’s environments and controlling temperatures without impeding traffic flow, the company says. The Mega-Pro HD combines the toughness and durability of an impact door with the flexibility and ease-of-use found in a swinging door. It was designed for use in large warehouses, storage facilities and other areas with constant workflow and high-impact traffic. The Mega-Pro can be used in doorways up to 10-feet wide and 10-feet high and features heavy-duty galvanized steel hardware that attaches to clear three-eighths-inch thick industrial-grade PVC that is available in both regular- and low-temperature grades. A spring-loaded design ensures that the door opens and closes consistently and all door components are housed within a heavy-duty frame that prevents the infiltration of dust, debris and other contaminants, the company says. In addition to effectively separating temperatures and managing environments, the Mega-Pro HD can reduce decibel ratings up to 35 dBA to create a safer and more Occupational Safety and Health Administration-compliant workplace. Optional impact plates can provide greater levels of durability.

• TMI LLC, 5350 Campbells Run Road, Pittsburgh, Pa. 15205; 412/787-3665; tmi-pvc.com.

Flexible solution

Bosch Packaging Technology released its SurePouch line of reclosable flexible pouches that are filled on the new SurePouch clean-fill machine series (SPC) roll-fed vertical form, fill and seal (VFFS) machines. The SPC can produce four different pouch formats for retail and foodservice. The EZPouch, EZGable and EZSquare formats have filling volumes from 100 milliliters to

5 liters and offer flexible applications for retail, according to the company. For foodservice, the EZPillow can hold up to 20 liters, allowing for easy and quick refilling, it adds. All formats are produced, filled and sealed with the same machine. Clean-filled applications for the SurePouch include non-carbonated beverages, water, dairy products and concentrates. The SurePouch system also is capable of filling viscous liquids up to 25,000 centipoises as well as particulates up to 25 millimeters in diameter and protects particulate integrity, according to the company. The machine also can handle dry bulk goods, including coffee. The new VFFS machine is capable of filling a variety of products and achieving hygiene standards up to ultra-clean fill, the company says. SurePouch packs also are fitted with reclosable spouts, which are ultrasonically welded to the exterior of the pouch and can be positioned in various locations. The spouts provide an enhanced hygienic feature as the product is filled directly into the pouch and not through the spout, the company says. The closure only comes in contact with the product when the consumer opens the package. The spouts are available in sizes of 10, 20 and 30 millimeters.

• Bosch Packaging Technology Inc., 869 S. Knowles Ave.,

New Richmond, Wis. 54017; 715/246-6511; boschpackaging.com.

Robotic bulk palletizers

Schneider Packaging Equipment introduced its new line of robotic bulk palletizers for high-speed bulk palletizing applications. Equipped with a Fanuc Robotics articulated arm, these robotic palletizers are able to handle a wide variety of unstable bulk products at significant speeds, the company says. Ideal for most bulk products including empty plastic or glass bottles, cans or other highly unstable products, the robotic bulk palletizer is designed to occupy minimal floor space and maximize flexibility and efficiency, it adds. Systems can be fully automated with slip and tier sheet dispensing, pallet dispensing, a product and pallet transport conveyor, stretch wrapping, labeling, and automated guided vehicles for a complete, fully automatic solution.

• Schneider Packaging Equipment Co. Inc., 5370 Guy Young Road, P.O. Box 890, Brewerton, N.Y. 13029; 315/676-3035; schneiderequip.com.

Green packaging

Tetra Pak unveiled four new features for its carton packaging portfolio that are aimed at strengthening the environmental attributes of several of its leading products, according to the company. The features include a separable top for the Tetra Evero Aseptic and three renewable polyethylene (PE) caps made from plant-based sources. In partnership with Brazil-based Braskem, Tetra Pak offers green PE caps that are made from sugar cane derivatives. Since July 2011, Nestlé Brazil has been packing two milk brands — Ninho and Molico — in Tetra Brik Aseptic packages using the green PE StreamCap 1000. Based on this successful trial, Tetra Pak launched green alternatives for the following caps: DreamCap 26, LightCap 30 and Helicap 27. The green caps will be distinguished from the original caps by a leaf logo, which will be carried on the cap. Following the launch of the Tetra Evero Aseptic, Tetra Pak developed the Tetra Evero Aseptic Separable Top, which has a perforation in the cardboard that enables the separation of a PE top from the carton sleeve, delivering improved environmental characteristics by making it easy for consumers to separate the top and carton sleeve for recycling, the company says.

• Tetra Pak USA, 101 Corporate Woods Parkway, Vernon Hills, Ill. 60061; 847/955-6000; tetrapak.com/us.

Sanitation improvement

BioSafe Systems has improved and reintroduced SaniDate 5.0. It now is approved to cover a broader range of human health pathogens, including Listeria, MRSA, Klebsiella pneumoniae, Streptococcus, human influenza virus and more. This is in addition to previously approved applications for Staphylococcus aureus, Escherichia coli and Salmonella enterica. Application surfaces include floors, walls, walkways, benches, tables, chairs, tractor trailers, refrigerators, evaporators, clean-in-place systems and other food and non-food contact surfaces. SaniDate 5.0 also is able to control algae, bacteria and fungi in a variety of water treatment applications. Many of these application rates were newly expanded to provide users with better disease control options. SaniDate 5.0 is available in

5-, 30-, 55- and 275-gallon sizes.

• BioSafe Systems LLC, 22 Meadow St., East Hartford, Conn. 06108; 860/290-8890; biosafesystems.com.

Price management solution

Vistaar Technologies Inc. announced the commercial availability of version 1.5 of its Distributor Price Management solution for beverage alcohol companies. Vistaar Distributor Price Management is a one-stop solution for mid-market beverage alcohol companies looking to better manage their price structures to reduce margin leaks, improve profitability and comply with state laws, the company says. Key highlights of Distributor Price Management 1.5 include the following: optimize the three-tier pricing structure from retail shelf price to Freight on Board (FOB); proactively and intelligently manage margins; analyze gross profit through reporting including leveraging weighted average models; and downstream integration to enterprise systems for FOB, list price, discounts and price support, according to the company. Vistaar Distributor Price Management provides transparency to the user community and enables collaborative decision-making across the sales, marketing and finance groups. This user-friendly solution equips business users to manage price and promotion changes and their associated ripple effects throughout the three-tier distribution network, it says. Rapidly deployable, Vistaar’s solution delivers short-term measurable business benefits and provides the foundational pricing infrastructure needed to grow business over time, the company adds.

• Vistaar Technologies Inc., 200 Lanidex Plaza No. 4, Parsippany-Troy Hills, N.J. 07054; 973/581-6300; vistaar.com.

ERP upgrade

Deacom Inc. released version 14.3 of the Deacom Enterprise Resource Planning (ERP) Software System. The enhancements made in the 14.3 release include a number of improvements to make current functions more efficient, added capabilities to boost a client’s warehouse operations and upgrades to the system that will improve the overall user experience, the company says. Substantial system enhancements were made in the inventory management and quality control (QC) functionalities and include a global unit of measure table, a master production calendar for job scheduling, new lot location capabilities, master lots and container tracking for license plating. Deacom also released two new supporting tools to the Deacom ERP Software System: a User Acceptance Test Script and a new Deacom Help System. The User Acceptance Test Script will assist customers with the testing of critical business functionality in all new Deacom build releases. The new Deacom Help System is a Web-based help system that provides supporting documents on the main Deacom application, the warehouse management system and the Deacom API library.

• Deacom Inc., 950 West Valley Road, Suite 3000, Wayne, Pa. 19087; 610/971-2278; deacom.com.

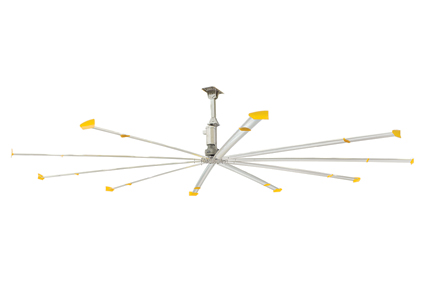

| Big Ass Fans’ newest product provides manufacturing solution |

|

A reinvention of its popular Powerfoil X industrial ceiling fan, Big Ass Fan Co. introduced the Powerfoil X2.0 fan this month. Developed in the world’s only research and development facility substantial enough to test large ceiling fans, this model further expands the coverage area of the original Powerfoil X model with the addition of a wash-down option and an array of purpose-built features in order to provide solutions for the strict standards of the food and beverage processing industry, the company says. Available as an optional upgrade, features include a stainless steel wash-down motor built to withstand frequent intense cleaning, food-duty paint and a completely sealed NitroSeal gearbox filled with food-grade oil. Its stainless steel extension tube, mount and hardware are nonporous, nonabsorbent and corrosion resistant, the company says. The Powerfoil X2.0’s overall design prevents the collection of food particles and the pooling of liquids for daily sanitization, it adds. This fan was developed in direct response to requests from food manufacturers for an air movement solution that would meet food production facility requirements. Although the optional wash-down upgrade is a new feature, the general principle behind the 8- to 24-foot-diameter Powerfoil X2.0 models remains the same. Large-diameter low-speed fans move a large volume of air gently and efficiently, making a person feel cooler by up to 10 degrees Fahrenheit, according to the company. Moving slowly in the winter, fans can be used to destratify heat by moving large volumes of air without creating a draft, it adds. The destratification of heat from the ceiling allows facilities to be more energy-efficient, and therefore cost-efficient, Big Ass Fans notes. Powerfoil X2.0 incorporates a new patented airfoil system to move air more efficiently than ever before, the company says. The system combines a patented airfoil and winglet design with new AirFence technology, which captures and redirects air sliding along the length of the airfoil. The Powerfoil X2.0 provides a 28 percent larger coverage area than previous models, the company says. The designers at Big Ass Fan Co. made 16 customer-driven changes to the Powerfoil X and implemented 198 quality checkpoints overall, but did not touch Powerfoil X’s original patented NitroSeal Drive, according to the company. Overall, the Powerfoil X2.0 is designed to provide large spaces with a reliable air movement solution, it says. • Big Ass Fans, 2425 Merchant St., Lexington, Ky. 40511; 877/244-3267; bigassfans.com. |

|

GEA: Total solutions provider for complete extended shelf life production lines |

|

GEA Process Engineering possesses the necessary know-how to design and manufacture hygienic, aseptic and sterile plants for the production of liquid products. GEA’s engineering solutions are able to retrofit an existing system or develop a completely new plant, the company says. With years of technical expertise, GEA Process Engineering works closely with product developers to custom engineer the best solution. The company is known for creating advanced systems for inline mixing and blending; de-aeration; carbonation; heat treatment, including ultra-high temperature processes; evaporation; distillation; membrane filtration; PET and HDPE bottle filling; aseptic processing and filling; sterile tanks; containment; product recovery; cleaning, such as clean-in-place; fermentation; and process integration and automation. GEA Process Engineering is a member of the GEA Group, a global technology group specializing in process systems and solutions. • GEA Process Engineering Inc., 1600 O’Keefe Road, Hudson, Wis. 54016; 715/386-9371; niroinc.com. |