Operating under the motto “Off-centered beers for off-centered people,” it should come as no surprise that Dogfish Head Craft Brewery, Milton, Del., is not bashful about creativity. Dogfish Head’s lineup includes 34 beers with ingredients and brewing processes inspired by a range of ancient recipes, music, collaborations and Founder and President Sam Calagione’s own ideas. Beyond its beers, the craft brewery’s off-centered approach also applies to its marketing activities, human resources efforts and business expansion plans.

Dogfish Head remains dedicated to both the creativity and processes that have grown the company from its start as a brewpub in nearby Rehoboth Beach, Del., to this year’s expected 170,000 barrel production, Calagione says.

“Even though we’re a sizeable regional brewery, we’re brewing the same way we were when we were the smallest brewery in the country: very experimental,” he explains. “Our average beer is 9 percent alcohol and made with six ingredients as opposed to the normal four ingredients.”

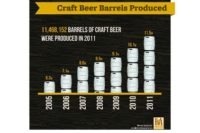

During the last 10 years, the brewery experienced scale growth rates ranging from 30 to 50 percent each year, Calagione says. In 2011, the company made an intentional decision to limit growth, he explains; Dogfish Head reported 20 percent expansion that year.

“We recognize we’re at a lucky position to make that choice because it’s a challenging economy,” Calagione says. “But at the scale we’re at, it got very hard for our co-workers, our quality of life and [created] anxiety about how much it took to grow 20 percent each year, and sometimes 40 percent or 50 percent. So 15 to 20 percent we think is a sustainable number, but over that was just too much.”

As a family-owned company, Dogfish Head places a high priority on quality of life for its 140 employees or co-workers as Calagione says. Cindy Dunson, human resources director for the company, says Dogfish Head strives to create a community or family-like atmosphere, which includes off-centered activities such as its weekly “Beer-Thirty” gathering on Friday afternoons, after-hours book club meetings and a company-wide small-batch brewing contest.

Even with its growth rate reigned in, Calagione says Dogfish Head is expecting 20 percent growth next year, which will place the brewery at more than 200,000 barrels in production. To accommodate continual expansion, Dogfish Head has a long-term plan to expand its Milton, Del., facility to become a 200-barrel brewhouse.

“We are making investments to continue to provide double-digit growth for our retailers, distributors and beer lovers, but we’re also focused more on strong growth than fast growth,” Calagione explains. “We have no interest in narrowing our portfolio, being less adventurous and focusing on a couple flagship beers, but we still feel an obligation to our co-workers and the marketplace to grow — just not too fast.”

‘Counterintuitive’ strategy

To reign in its growth, in late 2010 and early 2011, the company’s sales team, led by Vice President of Sales Adam Lambert, conducted a national evaluation of the company’s business plans and distributor relationships. Despite having detailed plans and goals with every wholesaler, the company went back to the drawing board starting with Delaware distributors and those in markets closest to the brewery. At the end of this evaluation, the company chose to remove distribution from four states, Canada and the United Kingdom to better focus on local markets, Calagione says.

“Pulling out of four states was a very emotional decision for the entire company, although we did this as a responsible business decision,” Lambert says. “It was tough for us, our distributors, our great retailers and all the awesome beer drinkers in those markets. With the growth we were experiencing close to home, we had to find beer to keep the local market supported.”

The brewery also requested that its wholesalers and sales team only service existing accounts and not open any additional ones for a period of time.

“If that state’s constantly running out of beer before the next truck can actually get there we said, ‘Hey guys, you can’t open new accounts because this is how much beer we agreed to sell this year, and if we don’t get this beer out and they’re getting more accounts, somebody’s not going to get what we promised them,’” Calagione says. “It’s a very delicate position to sell beer from, and it’s counterintuitive for a brewery to tell a distributor: ‘Please don’t take more beer than we agreed to.’”

With its scaled-back plan in place, the company began to open new accounts in the latter part of 2011, Lambert says.

Staying ‘social’

Adding new accounts is not only a challenge for Dogfish Head’s sales team, but also its marketing team, which focuses on grassroots marketing efforts through social media outlets. In addition to the company’s website, its more than 220,000 “likes” on Facebook and just more than 78,000 followers on Twitter, the marketing team, led by Vice President of Marketing Mariah Calagione, keeps tabs on the latest social media programs.

“I’m not saying any of these will be around forever, but we need to see where our consumers are online and where they want to come to us,” she says.

Dogfish Head is active on Google+, shares photos on Instagram and maintains a profile on Untappd, a network where members can share their favorite beers and on-premise locations. In early February, Dogfish Head created a profile on Gentlemint, an interactive online pinboard for men similar to Pinterest, Mariah Calagione says.

Social media outreach is an expansion of the company’s initial marketing strategy, Mariah Calagione says. “When we started in ’95, our main way to talk with customers was across our bar or at the table in our restaurant,” she says. “The way we grew at that point was with festivals and standing at beer stores and talking with individual customers. We still do that, but we also do that online.”

Through the years, Dogfish Head has noted an evolution of its consumers, Mariah Calagione says.

“We used to be able to say: ‘We’re a beer geek brewery. Beer geeks buy our beer. We’re all beer geeks, and we’re happy to be. We’re happy that they’re supporting us,’” she says. “But in the last couple of years, the core supporters have grown beyond the beer geek community more toward beer fans or beer aficionados, the bigger pool of people who are interested in dabbling and playing around with different beers just the same that happens with coffee, cheese and wine.”

Dogfish Head’s focus on grassroots marketing efforts helps the brewery connect with its consumers in its own off-centered way, Sam Calagione explains.

“While you might not see us on the Super Bowl halftime show as a sponsor or on billboards as you’re driving down the highway, when we post a beer dinner in a town on Facebook, Twitter or dogfish.com, it usually sells out within hours or days,” he says. “When we say a beer is going to be released … it drives that community to find it, and our specialty beers sell out.”

The company’s investment remains the creation of and commitment to Dogfish Head’s unique story and sharing that story with beer lovers to motivate them to find Dogfish Head’s releases, Sam Calagione says.

Story tellers

With a portfolio of 34 beers, Dogfish Head has a sizable task communicating the virtues of each option, but it’s one that the brewery embraces with resources dedicated to communicating the inspiration, ingredients and brewing process of each beer across sales, marketing and retail. In fact, the sell sheets the brewery shares with distributors are titled “Every beer has a story,” says Maria Grieshaber, marketing manager for Dogfish Head.

Within the first two months of 2012, Dogfish Head added two brand-new beers: Tweason’ale and Noble Rot. Tweason’ale is a sorghum-based certified gluten-free beer made with strawberries and buckwheat honey.

In addition to creating the recipes for Dogfish Head’s beers, Sam Calagione often provides direction, if not the actual artwork, for product packaging. In the case of Tweason’ale, he dreamed up a four-part novella telling the story of a strawberry and a bee who meet, fall in love and have a baby named Bee-Berry, which adorns the labels of bottles of Tweason’ale. He partnered with a designer to illustrate the love story across the sides of the beer’s four-pack cases.

The beer launched in January and has already received positive feedback from consumers who are affected by gluten sensitivity and celiac disease, Grieshaber says. Dogfish Head plans to release Tweason’ale four times a year.

In contrast to Tweason’ale, Sam Calagione not only created the recipe for Noble Rot, a saison-style ale made with grapes infected by the benevolent fungus botrytis, but also painted the label’s artwork. Botrytis is known as noble rot in the wine community, which inspired the product’s name and Sam Calagione’s artwork of the Dogfish Head logo rotting above a king.

“It’s kind of counterintuitive to probably any big brand-name strategy: We’re going to call something rotten and then we’re going to take our own logo and make it look rotten,’” he explains. “But it’s the same way that we’ll take a risk in recipes; we take beer seriously, but we don’t take ourselves really seriously.”

Noble Rot launched in late January and was immediately a hit with the brewery’s co-workers, Sam Calagione says. He notes that the company’s

co-workers receive a free case of one of Dogfish Head’s core beers each pay period, but he’s never seen Dogfish Head’s team get so excited to purchase one of its own beers as they were with the release of Noble Rot.

Dogfish Head expects both of the new releases to become part of the brewery’s regular rotation. “Five years from now, our ability to buy high volumes of botrytis-infected grape musk from Washington state will probably increase so that we will hopefully have grown [Noble Rot] from 400 barrels to 600 to 700 barrels, if we had that opportunity,” Sam Calagione says. “Whereas Tweason’ale’s immediate reception, the explosion of the gluten-free world and the fact that Dogfish has really been the first player to release an off-centered version of a gluten-free beer using exotic ingredients like buckwheat honey and strawberry … I think Tweason’ale could be a very significant thing for us in two to three years. This year alone, we’ll sell more Tweason’ale than any of the single brands of 750-ml. [packaged beers].”

Joining its previously released Bitches Brew, a bold dark beer meant to be a companion to the Miles Davis album of the same name, and last year’s Faithfull Ale, which honored the 20th anniversary of rock band Pearl Jam with a Belgian-style golden ale made with black currants, the brewery is working on its latest music-inspired collaboration project. This year, Dogfish Head is working with hip-hop band Deltron 3030 on a hybrid cider-beer called Positive Contact that will be released in conjunction with the band’s follow-up to its 2000 debut album.

Named after a song on the band’s first album, Positive Contact was custom-created to suit the palate of Deltron 3030 member Dan the Automator, Sam Calagione says. The product is a 9 percent alcohol-by-volume hybrid cider-beer made with wood-pressed Fuji apples, roasted faro, cayenne peppers and fresh cilantro, the company says. Later this spring, the company will release 9,000 cases that each contain six 750-ml. champagne-style bottles of Positive Contact, a 10-inch vinyl record of four exclusive Deltron 3030 remixes and a list of recipes from renowned chefs that were inspired by the music and the beer.

“The idea is that six people can take this home and have a house party where they make the food, listen to the music and drink the beer,” Sam Calagione says. “Hopefully it gets them talking about Dogfish, Deltron 3030 and the chefs. We’re trying to connect all those communities in a way that none of us are really advertising, we’re just sharing and hoping that they like it.”

New releases

Positive Contact is a prime example of the Dogfish Head team’s dedication to new projects. “We all have our roles in this beer that we’ve never produced in volume more than 10 kegs before, and that frankly is going to be less than one-fifth of 1 percent of our sales this year,” Sam Calagione says. “But we’re putting dozens of hours into it each, instead of just focusing on the 48 percent of our sales that is 60 Minute IPA and making that bigger. A lot of public companies would say that’s stupid, especially fiscally.”

Dogfish Head’s new product development begins the same way that it has since the company opened its brewpub in 1995. Sam Calagione thinks of an idea and a list of ingredients and makes a test batch on the brewpub’s scaled-down brewing system. The test batch will be shared with brewpub visitors, who can choose from a variety of Dogfish Head beers and brewpub exclusive batches.

“We have seven brewpub exclusive beers on tap at the brewpub,” Mariah Calagione explains. “Maybe one or two of them will end up being packaged some day, but [the customers] don’t know which ones, and sometimes even we don’t know which ones are going to be packaged. They are involved in the process of trying them out and giving feedback on every beer that we make there.”

This feedback from customers at its brewpub substitutes any focus groups, Sam Calagione says.

“Our regulars are paying us $4 or $5 per pint; they’re going to tell you the truth on how they feel,” he explains. “You know, ‘Hey, thanks for this,’ ‘It’s too spicy,’ ‘This one’s too that,’ or ‘This one’s awesome.’ That’s really all we do for market research is listen to the people that helped us grow.”

At the brewpub, Dogfish Head uses a “snowflake philosophy” in which each batch can be different, Sam Calagione says, but if the company chooses to go into production with a beer, consistency must be reached in the recipe and process. At that point, Sam Calagione condenses the ingredients, recipe, desired alcohol by volume and any special processes and shares it with the company’s brewers, including Brewmaster Tim Hawn, who develop the commercial recipe while additional Dogfish Head team members work on sourcing ingredients, sales plans and choosing packaging.

The company’s motto also plays a part when it comes to a beer’s commercial production, explains Chief Operating Officer Nick Benz.

“Off-centered is what we do,” Benz says. “The ideas that come out of Sam’s head, how we do it and how we come up with the right way to do it, that’s also off-centered. Once we determine that off-centered way, everybody has to follow that way or else we don’t make the same beer every time, we don’t make the same food in the kitchen or spirits in the pub. Sometimes there’s this external perception of ‘Wow, that must be total anarchy, chaos, fly-by-the-seat-of-your-pants and make it up as you go.’ That’s true during our [research and development] and experimental phases, but once we determine what we’re going to do, customers in any industry expect consistency and that’s what we aim to deliver.”

Prior to a product’s release, Dogfish Head shares the beers at festivals and events to collect additional feedback. In early February, Sam Calagione attended the Extreme Beer Festival in Boston where Dogfish Head sampled the recently released Noble Rot and Positive Contact, which is still in development.

At its core

New releases join the brewery’s portfolio, which includes seasonal and limited-edition varieties as well as its seven core brands that are available year-round: 60 Minute IPA, 90 Minute IPA, Raison D’Etre, Midas Touch, Indian Brown Ale, Burton Baton and Palo Santo Marron. Although 60 Minute IPA dominates the brewery’s sales, maintaining a flagship brand is not what Dogfish Head necessarily intends.

“We’re probably the only brewery in the country that celebrates when their flagship is down as a percentage of their sales,” Sam Calagione says. “Just in the last two years, 60 Minute IPA has dropped from 51 percent of our sales; in 2010 it was 49 percent, and in 2011 it was 48 percent of our volume.”

Dogfish Head’s 90 Minute IPA is the company’s second best-seller and makes up about 18 percent of its sales, Sam Calagione says. The remainder of its core brands have each reported double or triple digit percentage growth from a smaller volume base than 60 Minute IPA, he explains.

Within Dogfish Head’s portfolio, the company has 18 different price points. The suggested retail price of a beer is set using a formula of the ingredients, utility and time it takes to create a beer compared to the company’s 60 Minute IPA, Sam Calagione says. For example, one of its core brands Palo Santo Marron, an unfiltered brown ale, carries a higher price tag than a traditional lager, he explains. Palo Santo Marron is 12 percent alcohol by volume and is made with more than 2.5-times the ingredients than a traditional beer. It also ferments for one month in stainless tanks, and then is transferred to a handmade 10,000 gallon tank made from palo santo wood imported from Paraguay, which mellows the hoppiness of the beer, Sam Calagione says.

“Over two months — that means it took almost three-times the ingredients, six-times the time and utilities, and that loss of opportunity to fill that tank with other beers,” he says. “All those things are factored into why Palo Santo Marron costs more, but it still doesn’t cost hundreds of dollars. It’s a premium — maybe two- or three-times an inexpensive light lager — but still affordable.”

Dogfish Head also dedicates time and resources to its other wood-aged beers, cask-conditioned beers and bottle-conditioned beers. These processes often require additional energy and occasional hand-packing, but it’s worth it to the brewery, Sam Calagione says.

“We call it blissfully inefficient, where it’s a conscious choice for us to say, ‘Let’s spend a bunch of our time, energy and resources on this project instead of this giant batch of 60 Minute IPA all day long,’” he says. “We love 60 Minute IPA, but we love all our children equally, and they’re all our children.”

One of its cask-conditioned releases, 75 Minute IPA, is a blend of its two best-sellers, 60 Minute IPA and 90 Minute IPA, that is dry-hopped with whole-leaf Cascade hops and cask-conditioned with maple syrup from Sam Calagione’s family farm in western Massachusetts. Sam Calagione explains that the process, which is made in a homemade tank dubbed Johnny Cask, imparts 75 Minute IPA with softer bubbles, sweet subtle notes and complexity.

The brewery’s unique processes also are factored into the sales tactics, Lambert says.

“We are very focused on educating our distributors and retailers not only on how our beers taste, but how we make them and what sort of proprietary processes and equipment we use,” the vice president of sales explains. “Taking the time to explain how we found the ingredients and complexities of flavors is serious work and falls in line with being off-centered.”

To promote its various styles of beer, Lambert’s team also creates off-centered events. For its Ancient Ales beer dinner series featuring its

Chateau Jiahu, Sah’tea, Theobroma and Ta Henket beers, the company challenges restaurants in different markets to create a menu that complements Dogfish Head’s “liquid time capsules,” he says. BI

| Innovation starts at Dogfish Head Brewings & Eats |

|

Dogfish Head Craft Brewery began as a brewpub in Rehoboth Beach, Del., in 1995. In the early days, the company’s Founder and President Sam Calagione spiced up his brewing routine by adding handfuls of ingredients he snagged from the brewpub’s kitchen. The company brewed two to three times a day, five to six days a week on a homemade brewing system made of repurposed kegs the brewery called Sir Hops Alot. Just as American music fans moved on from one-hit wonder rapper Sir Mix-a-Lot, Sir Hops Alot was retired after one year when Dogfish Head purchased five barrel tanks from a local cannery that was going out of business. Today, Dogfish Head’s do-it-yourself approach continues as the brewpub’s brewery operates on a system made from repurposed yogurt tanks. But it’s still where the brewery’s innovations start out. Calagione’s ideas begin in small batches worked out on the brewing system, which, he admits, is the only system that he knows how to brew on. “I’m the least technically skilled brewer at our company,” Calagione says. “I’m proud to say that, but I’m still the guy who comes up with what we’re going to produce next, at least in terms of what we’re thinking about bringing all the way into distribution. I love that part of what I do.” As its production scale brewery has increased, the brewpub, known as Dogfish Head Brewings & Eats, maintains a necessary place in the company’s plans, he explains. “The brewpub will always be the birthplace of the company, but I think it’s really cool that it’s still where the first stages of our experiments come to life,” he explains. “While now it pales in comparison in terms of revenue to our production brewery, it’s equally integral to the success of our company because we’re not a company that believes in traditional advertising. “We have grown because we just try to share our beer with people and make it unique enough that it resonates, quality enough that they enjoy it and then hopefully they will go out and spread the word. The pub is ground zero for that,” he concludes. The brewpub hosts up to seven exclusive beers every day, including some beers that might be in experiments for production, Calagione explains. Possibly without their knowledge, visitors to the brewpub help to shape the next iterations of the beers by providing feedback on the beers. This helps the brewpub staff to tweak the recipes of the beers for the next batch — or to adapt the recipe prior to commercial production, the company says. The notoriety of the Dogfish Head brand has increased the traffic to the brewpub, which is especially popular during the summer months with Rehoboth Beach’s tourists. “In the summer it can be a really long wait, but a lot of people make the pilgrimage and they’re going to wait it out,” says Maria Grieshaber, marketing manager for Dogfish Head. “The atmosphere is like everybody’s waiting for the same thing, it’s that anticipation of waiting to get in: I heard about this beer and I’ve been wanting to try it, or I saw that guy on the [Discovery Channel’s ‘Brewmasters’] show.” It’s also where the company sells 90 percent of its Dogfish Head craft spirits, which are made in the brewpub on scrap yard-sourced equipment dubbed “Frakenstill.” Its off-centered jin and varieties of naturally flavored rums and vodkas are popular with brewpub visitors and tourists visiting Rehoboth Beach, says Nick Benz, the brewery’s chief operating officer. Similar to the brewery’s downsizing of its beer availability, the company chose to focus on Delaware and removed its spirits distribution from New Jersey, Maryland and northern Pennsylvania. “Typically the excitement for the off-centered spirits is proportionate to the excitement about our beers, albeit on a much more local level,” Calagione says. “We’re already looking to put out 15 or 20 percent more spirits in 2012 than we did in 2011, and are hopeful that that trajectory can continue to improve.” Dogfish Head’s lineup of spirits include flavored vodkas, including peanut butter variety, rum made with wildflower honey, and jin, its off-centered release of gin featuring black pepper and whole-leaf hops. |

| The making of El Diablo Verde |

|

As part of its commitment to creating a family-like work atmosphere, Dogfish Head Craft Brewery, Milton, Del., offers a variety of activities during and after work hours for its 140 employees, including weekly “Beer-Thirty” social gatherings, book club meetings and its internal Small Batch Brewing competition. Patrick Staggs, director of operations for the brewery, handles the Small Batch Brewing program that was designed to get everybody at the brewery involved in having even more of a share of Dogfish Head’s signature sense of creativity and experimentation, he says. The Small Batch Brewing program invites employees from any department to create a team, brainstorm a recipe and brew their beer on Dogfish Head’s systems with ingredients purchased by the company. The teams take half home and share half with their co-workers, who help judge the beer, Calagione explains. This year’s winners created an India Pale Ale that was just under 7 percent alcohol, heavily hopped with 80 International Bittering Units and made with fresh jalapenos and cilantro. With its Hispanic-inspired ingredient list, the team gave the beer the in-house name of Mexicali IPA, but after the beer was pronounced the winner, the team realized that Mexicali IPA did not live up to the Dogfish Head standard of cleverly named beers. Thus, the beer was re-christened El Diablo Verde. El Diablo Verde is offered on tap at Dogfish Head Brewings & Eats. The winners will travel to New York City for an overnight trip to visit La Birreria, the beer garden at Mario Batali’s Eataly restaurant that features Dogfish Head beers. |