|

For several years, light emitting diode (LED) lighting has been making steady improvements in quality, efficiency and cost. Is it ready for prime-time?

The answer is: “it depends.”

LEDs are making great inroads in freezers where they have two big advantages: extended service life and dramatic energy savings through aggressive on-off cycling.

LEDs love the cold, which can double their already impressive life expectancy versus other lighting sources.

Although there is a significant wattage reduction just by switching to LEDs due to their higher efficiency versus other lighting sources, the largest savings opportunity is a result of LEDs’ ability to be cycled on and off by motion sensors. The life of an LED is not shortened by frequent cycling, and LEDs achieve instant-on illumination to full, or more than full, brightness — a quirk about LEDs is that the initial output is brighter than the warmed up LED.

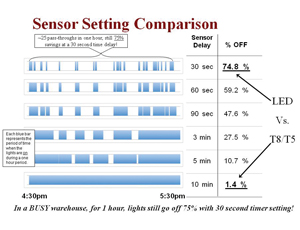

Truly staggering savings can be achieved with an aggressive control strategy, for example, using a mere 30-second time delay before turning lamps off once the motion sensor sees no movement. The norm in the lighting industry has been to set a time delay at about 10 minutes because historically, anything shorter killed fluorescent lamp life.

Freezer activity typically is fast-moving in spurts throughout the day and a passive infrared (PIR) sensor easily picks up a warm body or forklift crossing its path. An aggressive 30-second time delay works surprisingly well.

Imagine a very busy warehouse where every two minutes someone walks or drives down an aisle, stops to grab a product and moves on. In this active scenario, the lights would come on for approximately 30 seconds and then go off for the next 90 seconds. This means the lights are off 75 percent of the time, and this is at peak activity levels.

In slow times, you would be looking at 90-percent-plus off-time. The chart at the left shows how the aggressive time delay generates the off-time.

Add to this the wattage reduction from replacing 455 watts of metal halide with approximately 160 watts of LED and you can achieve a 90-percent kWh reduction in lighting energy usage.

In addition, by aggressively cycling LEDs, you can cut the refrigeration load (and energy cost) by almost the same 90 percent, as the cooling primarily is fighting the lighting system 24/7 in most applications.

Quality LED fixtures that replace a 400-watt-high bay fixture cost in the range of $500-$700, but continue to drop. Utility incentives exist throughout the country in most locations that can help offset the cost and improve the return on investment (ROI).

In ambient temperature warehouses, the T5 and T8 fluorescent fixtures still deliver a better ROI, but the LED fixtures are likely to catch the fluorescents in a few years, if not sooner, as prices keep dropping and LED efficiency improves.

A Fortune 500 distribution center has installed LEDs in a freezer at a 45-foot mounting height. The motion sensor works unusually well in the freezer as it easily detects a warm body moving toward the light fixture. The LED fixture illuminates when workers are more than 30 feet away, providing ample time to have the light ready as needed, even when they are approaching quickly.

In addition to selecting the proper lighting technology for a given application, there is another element of lighting design that has a major impact on the total lifecycle value of a lighting retrofit project.

Most plants have changed equipment layouts and added complexity to their facilities with production lines, palletizer/depalletizer machines and other obstructions — and a one-for-one approach misses the opportunity to truly engineer a solution. An engineered solution considers productivity, safety, quality and morale by properly designing the light levels for each task while also improving how accessible each fixture is for future maintenance.

For example, if an existing fixture is in a difficult-to-reach location, the upgrade provides an opportunity to rethink the area to determine how to illuminate the task while positioning the new fixture in an easy-to-reach location.

A palletizer machine also is the perfect opportunity to rethink the lighting strategy. Usually the existing lights were designed for a high bay application, but the machine can cut the height in half, making the fixture spacing obsolete for that application. Upgrading the lighting with a one-for-one approach just replicates the problem with more efficient fixtures.

The proper design for a palletizer would be to include more fixtures of a lower power, located for easy access and designed for a mounting height in the 10-foot range. This may seem like common sense, but it requires an engineered solution instead of a one-for-one simplistic approach. BI